Ring test tooling

A technology of retaining rings and tooling, applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate test results, large axial displacement of retaining rings, and easy injury to test personnel, so as to reduce the probability of fracture and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

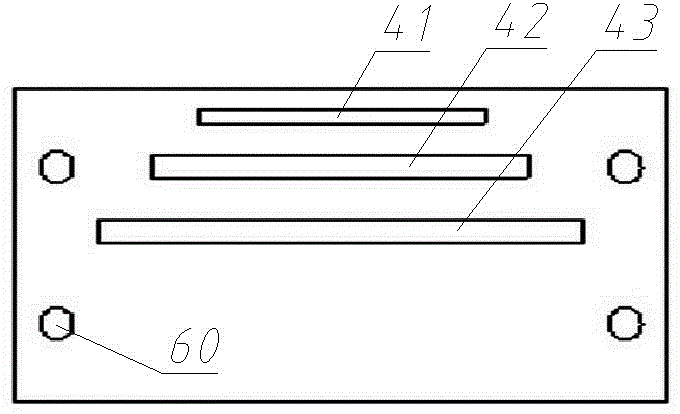

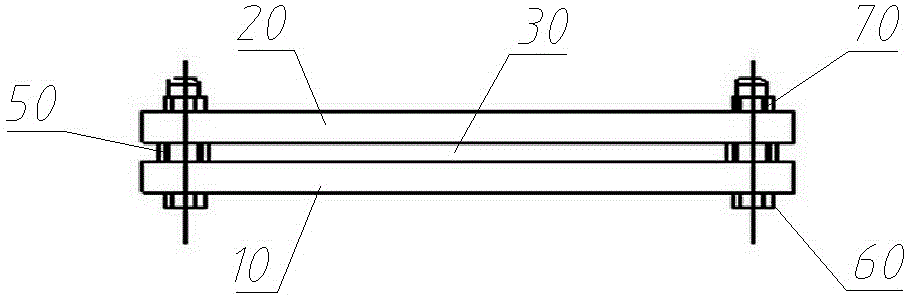

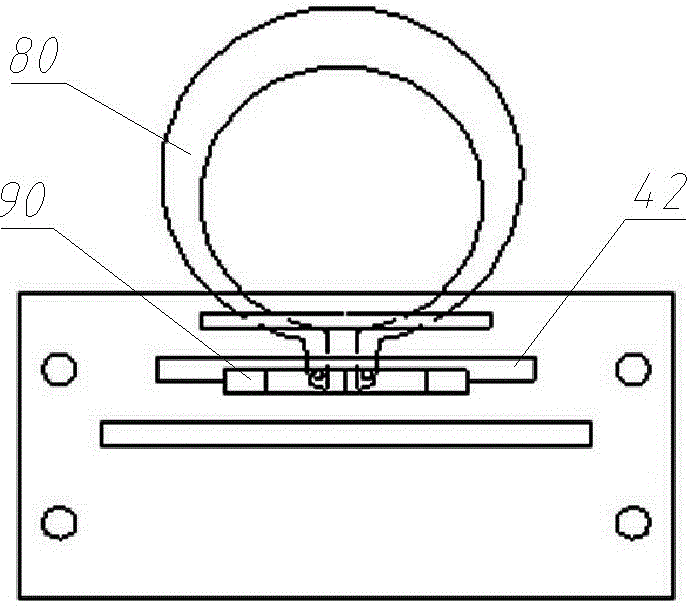

[0018] An example of the retaining ring test fixture of the present invention is Figure 1~Figure 5 As shown, it includes a front limiting plate 10 corresponding to both axial sides of the retaining ring 80, a rear limiting plate 20 and a gasket detachably arranged between the front limiting plate 10 and the rear limiting plate 20 50. The gaskets 50 are arranged in series, and the thickness of each gasket in the series corresponds to the seam gauge of the retaining ring 80 of the corresponding specification. When it is necessary to test the corresponding retaining ring 80, the gasket 50 of the corresponding thickness is selected in the series. Can.

[0019] Among them, the spacers 50 are provided with four identical ones, respectively corresponding to the four corners of the front limiting plate 10 and the rear limiting plate 20, and are connected with the front limiting plate 10 and the rear limiting plate 20 by bolts 60 and corresponding The nuts 70 are detachably fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com