Double-sided adhesive tape, manufacturing method thereof, and method for pasting double-sided adhesive tape on FPC products

A manufacturing method and double-sided adhesive technology, applied in the direction of printed circuit manufacturing, adhesives, film/sheet adhesives, etc., can solve the problems of affecting environmental sanitation, inconvenient, not easy to clean, etc., to improve efficiency and avoid The effect of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

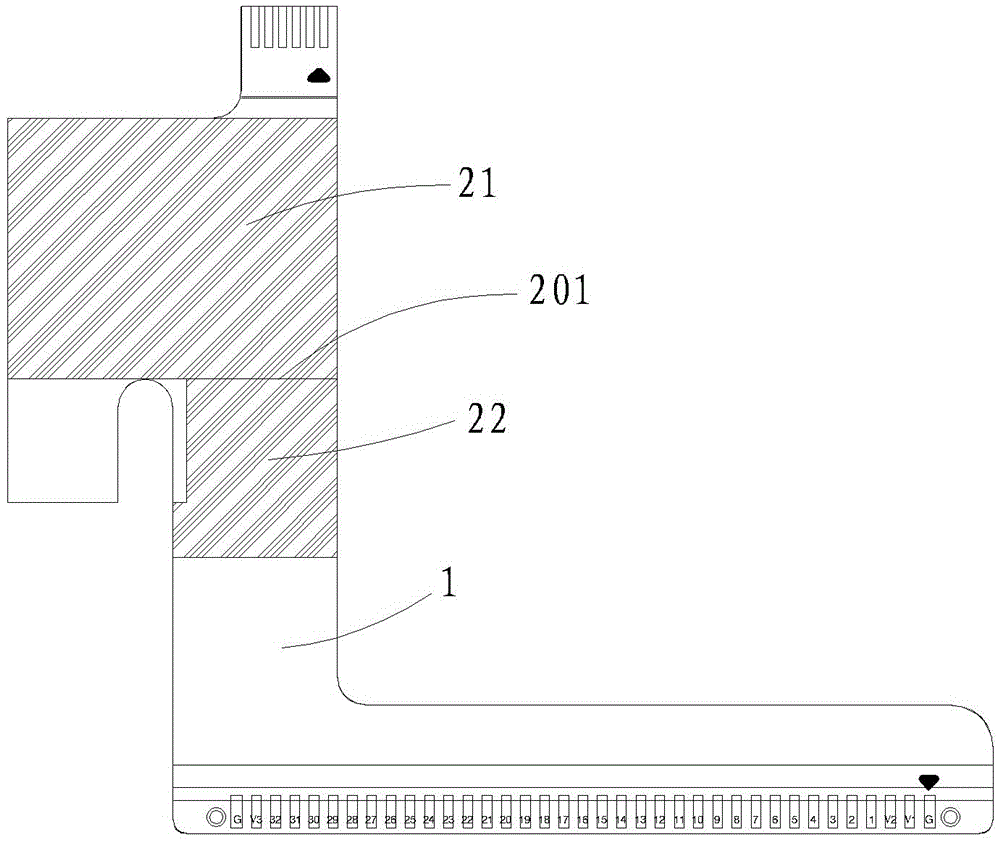

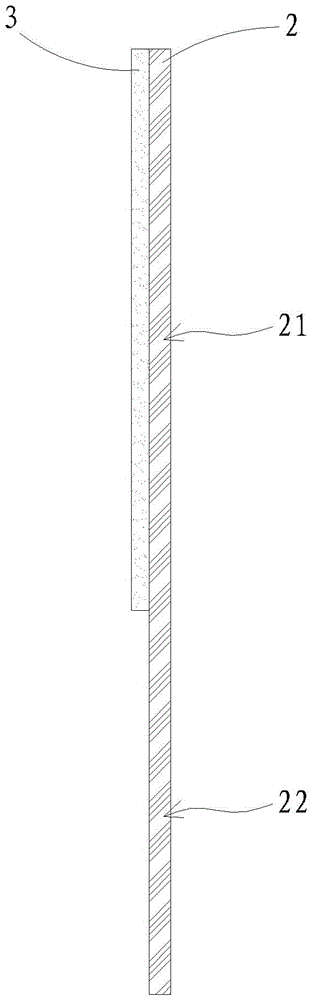

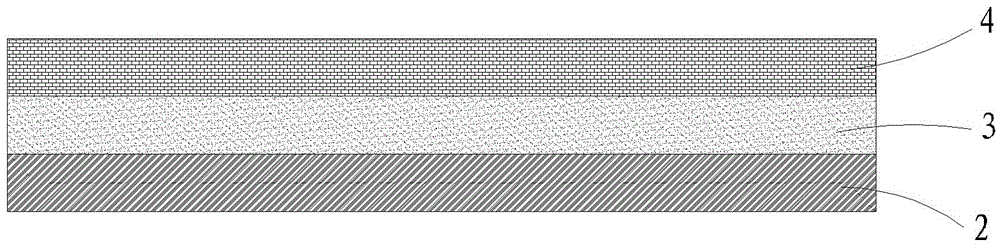

[0047] The present invention proposes a method for manufacturing double-sided tape, which uses secondary punching (cutting) and two layers of self-contained release paper to make double-sided tape, which can be easily pasted to FPC products (FPC The imposition product, the same below, will not be repeated), thereby improving the work efficiency and avoiding the debris generated by the prior art by peeling off the self-provided release paper on the double-sided adhesive layer of each set adhesive area one by one. Specifically: first paste the self-prepared release paper to the double-sided adhesive layer of the double-sided adhesive material, and then perform the first punching (cutting) to connect the release paper adhesive area corresponding to each unit piece with the release paper. The dividing line of the paper handle and the adjacent dividing lines are connected to each other by a line that does not interfere with the overall shape used for the sticking operation to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com