Chilling agent

A chiller, weight percentage technology, applied in the field of chiller, can solve problems such as difficult to find eutectic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1, the chiller includes the following components, by weight percentage, tellurium 45%, aluminum 20%, titanium 10%, iron 25%, and the above-mentioned components are made into particles of 0.5-1.5 mm and then uniformly mixed to form the chiller. refrigerant.

Embodiment 2

[0011] Embodiment 2, the chiller includes the following components, by weight percentage, tellurium 55%, aluminum 30%, titanium 10%, iron 5%, and the above-mentioned components are made into particles of 0.5-1.5 mm and then uniformly mixed to form the chiller. refrigerant.

Embodiment 3

[0012] Embodiment 3, the chiller includes the following components, by weight percentage, tellurium 50%, aluminum 30%, titanium 10%, iron 10%, the above-mentioned components are made into particles of 0.5-1.5 mm and then uniformly mixed to form the chiller. refrigerant.

[0013] Spread the chiller evenly on the bottom of the thermal analysis sample cup to measure the addition of molten iron in the thermal analysis sample cup.

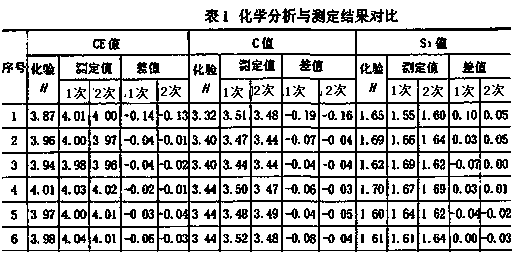

[0014] Such as figure 1 As shown, after using the chiller provided in Example 3 to detect both sides of the molten iron with different components, the CE, C, Si value data and their comparison with the results of the chemical analysis of the same molten iron can be seen The accuracy of the measurement results after the invention is used is high, and the measurement stability is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com