Yarn break stop system

A technology of yarn breakage and yarn, applied in looms, textiles, textiles and papermaking, etc., can solve the problem that the weft cannot be shut down in time, and achieve the effect of shutting down in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

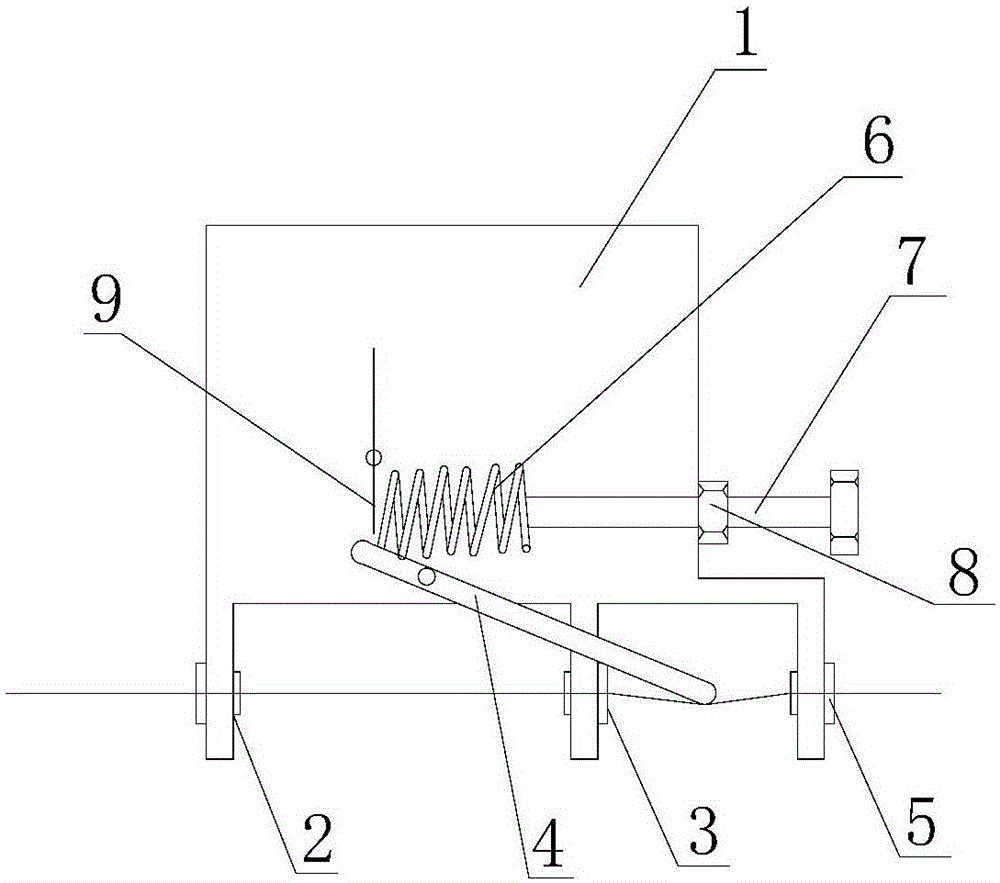

[0014] Such as figure 1 As shown, a yarn breakage shutdown system includes a tension adjustment box body 1. Outside the tension adjustment box body 1, the tension adjustment box includes a wire inlet 2, a wire inlet 2 3, a tension Bracket 4 and outlet hole 5; in the tension adjustment box body 1, the tension bracket 4 is hinged with the tension adjustment box, the bottom end of the tension bracket 4 has a spring 6, and the other end of the spring 6 is fixedly connected with an adjustment bolt 7, and the adjustment bolt 7 The middle part is fixed on the tension adjustment box body 1 by a nut 8, and one end of the adjustment bolt 7 is located outside the tension adjustment box; the box body also has a switch 9 for controlling the opening and closing of the loom, and one end of the switch 9 is connected to the tension adjustment box The body 1 is hinged, and the other end of the switch 9 is located at the rear end of the bottom end of the tension bracket 4 along the direction of ...

Embodiment 2

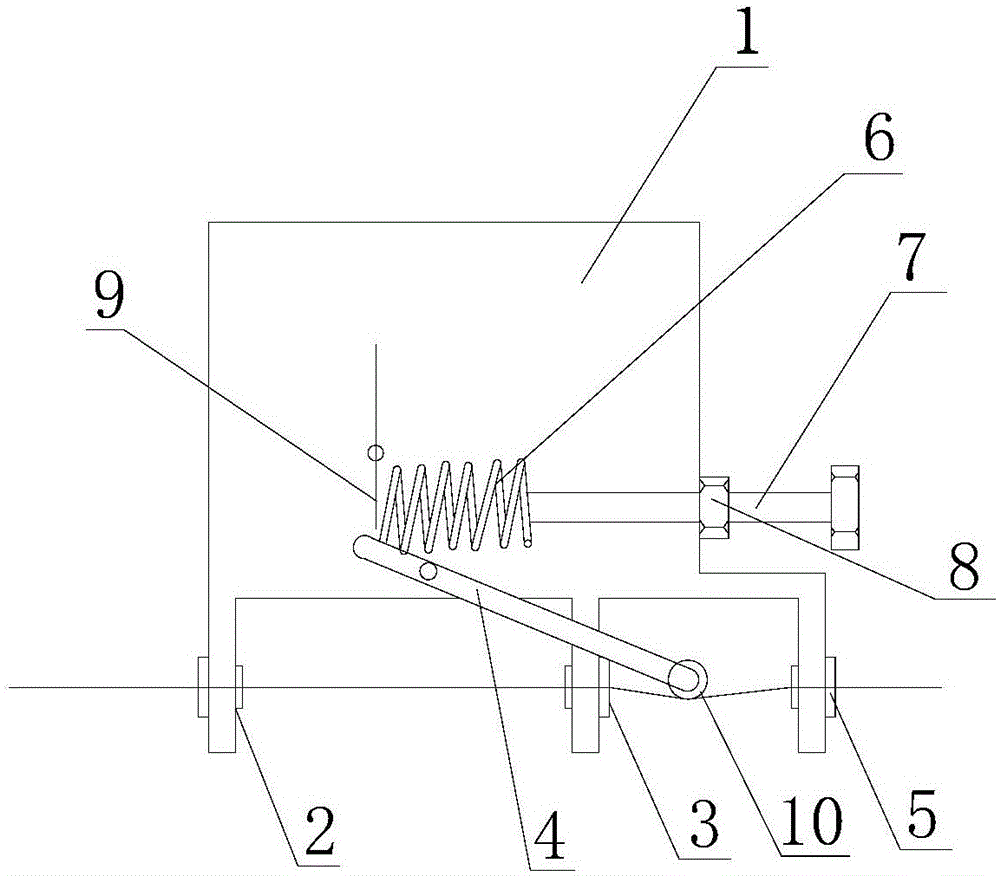

[0017] As an improvement of Example 1, the contact between the tension support 4 and the yarn has a rolling ring 10, so that the sliding friction between the tension support 4 and the yarn is changed to rolling friction, which reduces the wear of the yarn , to a certain extent reduces the probability of yarn breakage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com