Hanger base structure and hanger with same

A technology of basic structure and hanger, applied in the field of hanger's basic structure and hanger, can solve the problems of large size, many parts, complex structure, etc., and achieve the effect of not easy to lose and easy to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

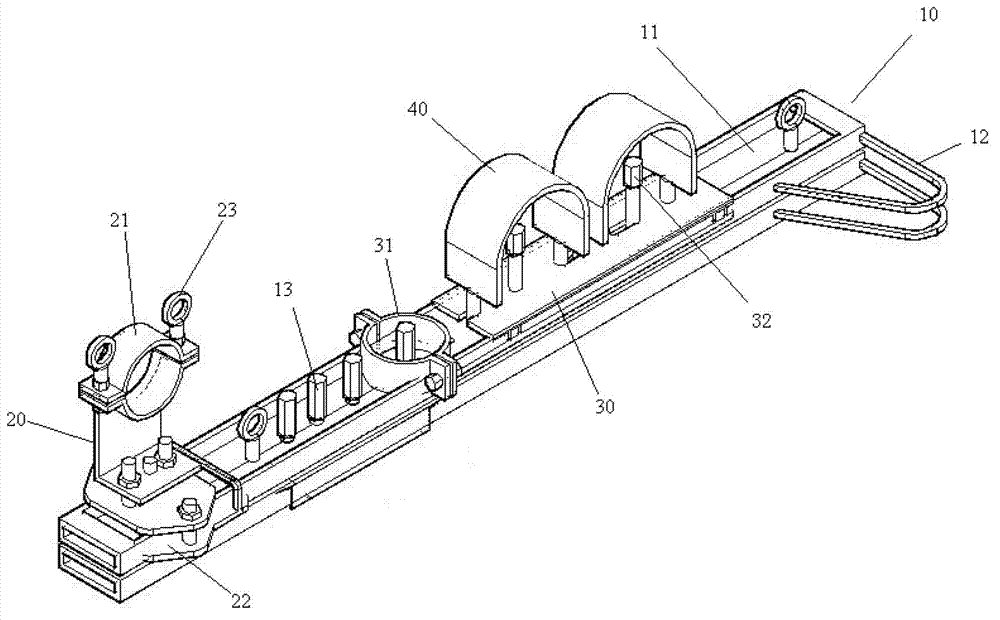

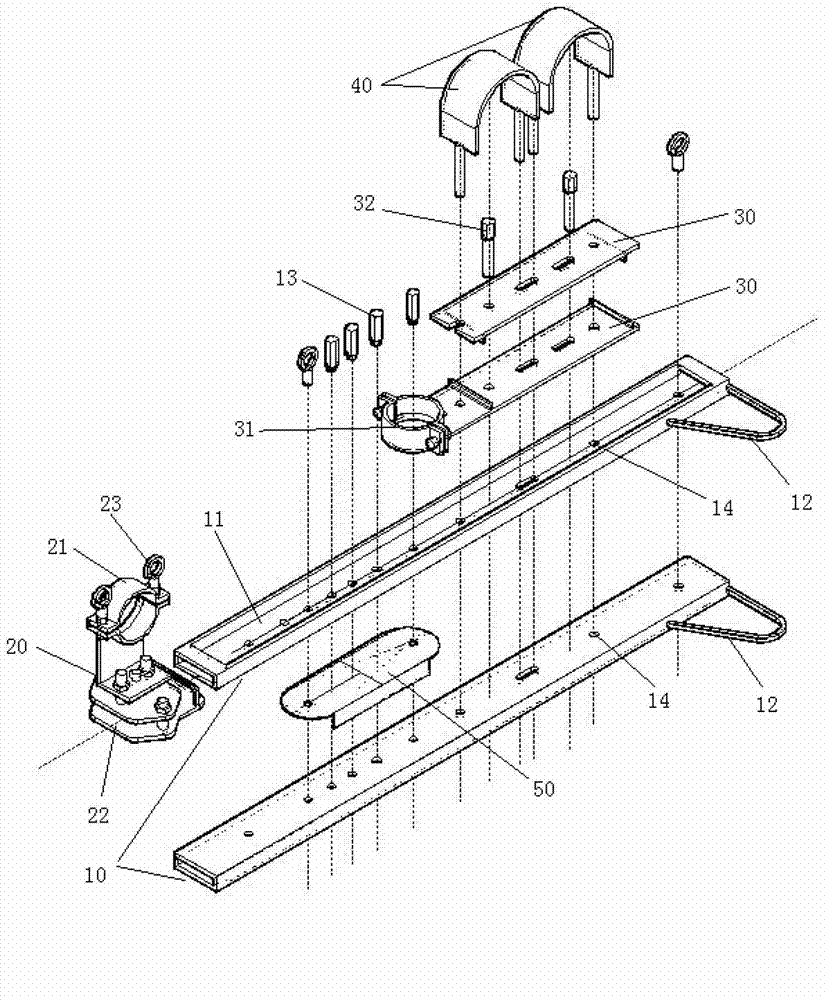

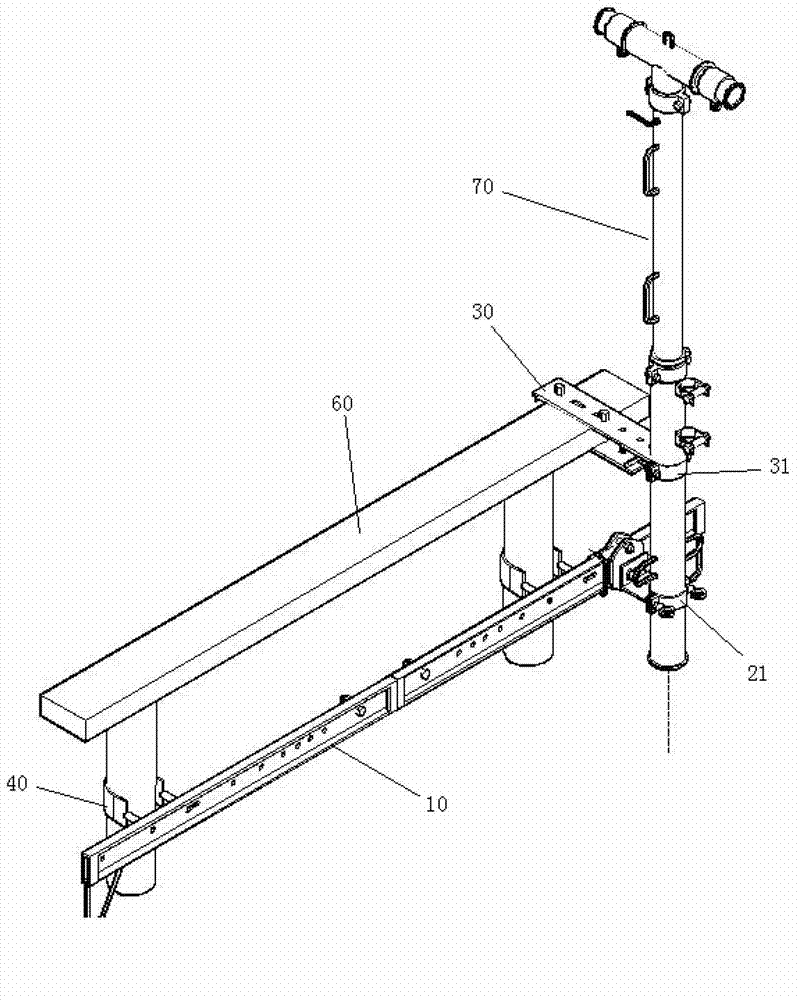

[0021] Such as figure 1 and figure 2 As shown, the basic structure of the hanger of the present invention includes: a base plate 10 and a connecting sleeve 20, wherein the base plate 10 is provided with a groove 11 along its longitudinal direction, and the bottom of the groove 11 is provided with a plurality of bolts for installation Holes 14 , preferably, one bolt 12 is provided on each bolt installation hole 14 . The connecting sleeve 20 is sheathed on one end of the base plate 10 through the receiving space 22 thereon, and the connecting sleeve 20 is provided with a first hanger body mounting portion 21 , which is preferably a sleeve structure. The first hanger body installation part 21 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap