Perforator provided with built-in detonating cord extrusion-type bullet fixing component

A detonating cord and extrusion type technology, applied in the field of perforators, can solve the problems of difficulty in reaching the maximum blast height of a perforating cartridge gun, a worn detonating cord, and unreliability, and achieves good on-site application effects. , The effect of improving the blasting height in the gun and increasing the stability of the gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

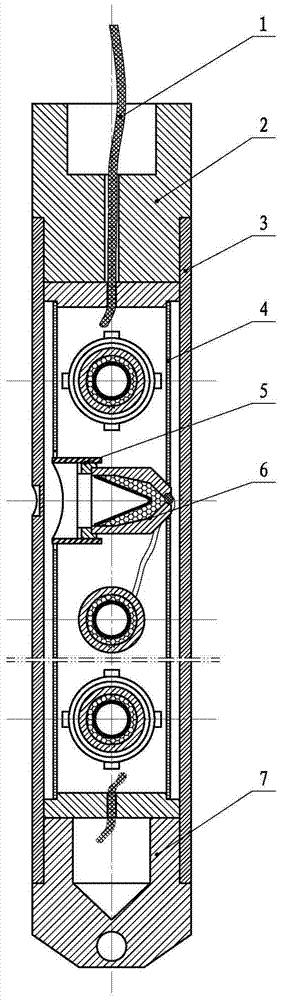

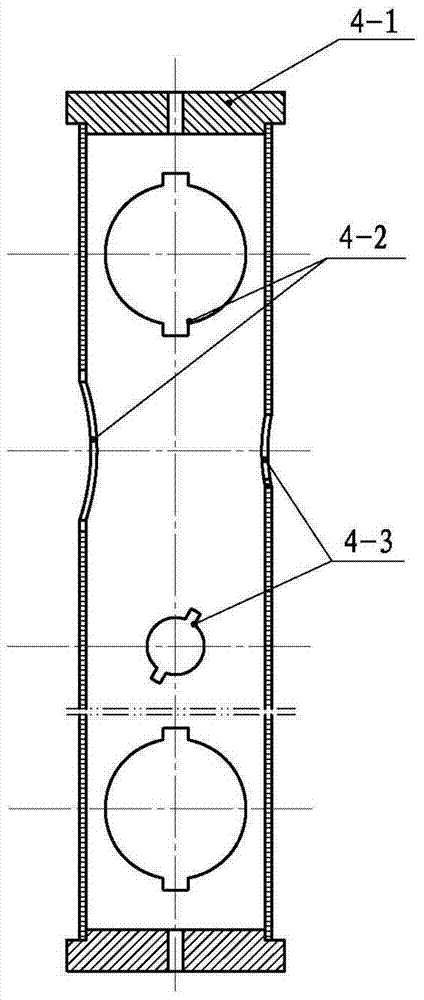

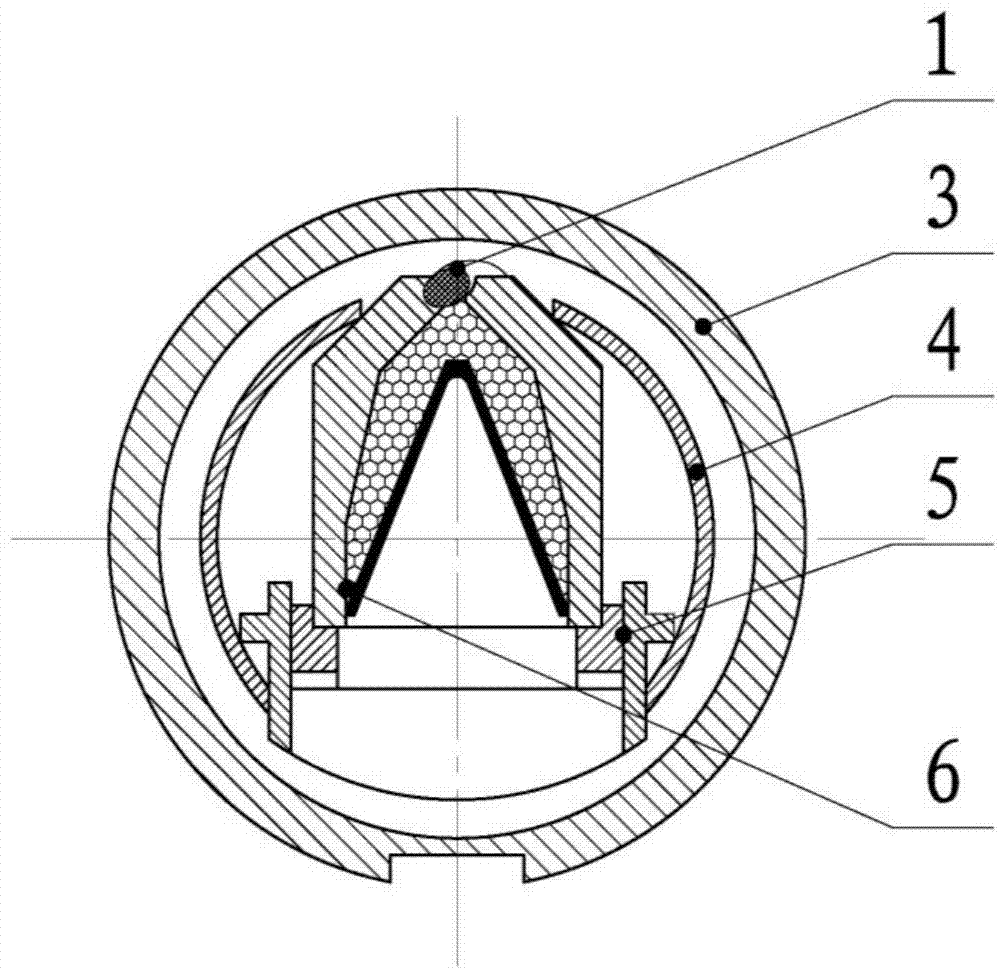

[0024] Specific examples are as follows: According to figure 1 The provided perforator with built-in detonating cord extruded fixed bullet assembly includes detonating cord 1, gun head 2, gun body 3, bullet holder tube 4, fixed bullet sleeve 5, perforating bullet 6 and gun tail 7 . It is characterized in that: on the outer wall of the bomb holder tube 4, a plurality of bullet loading holes 4-2 and bullet fixing holes 4-3 are arranged in parallel and spirally, and the centers of the bullet loading holes 4-2 and the bullet fixing holes 4-3 are on the same axis Above; in each charging hole 4-2, there is a ring-shaped fixed bullet sleeve 5, the axis of the fixed bullet sleeve 5 is perpendicular to the loading hole, and is located at the mouth of the perforating charge 6; The solid elastic sleeve 5 includes an outer ring 5-1 and an inner ring 5-2. The inner ring 5-2 rotates inside the outer ring 5-1 and moves up and down through threads. There are two symmetrical rings on the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com