A anti-seepage structure and construction method of smw construction method pile shield portal

A technology of water seepage structure and construction method, which is applied in earthwork drilling, wellbore lining, tunnel lining and other directions, can solve problems such as water seepage, and achieve the effect of saving construction cost, increasing stability effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

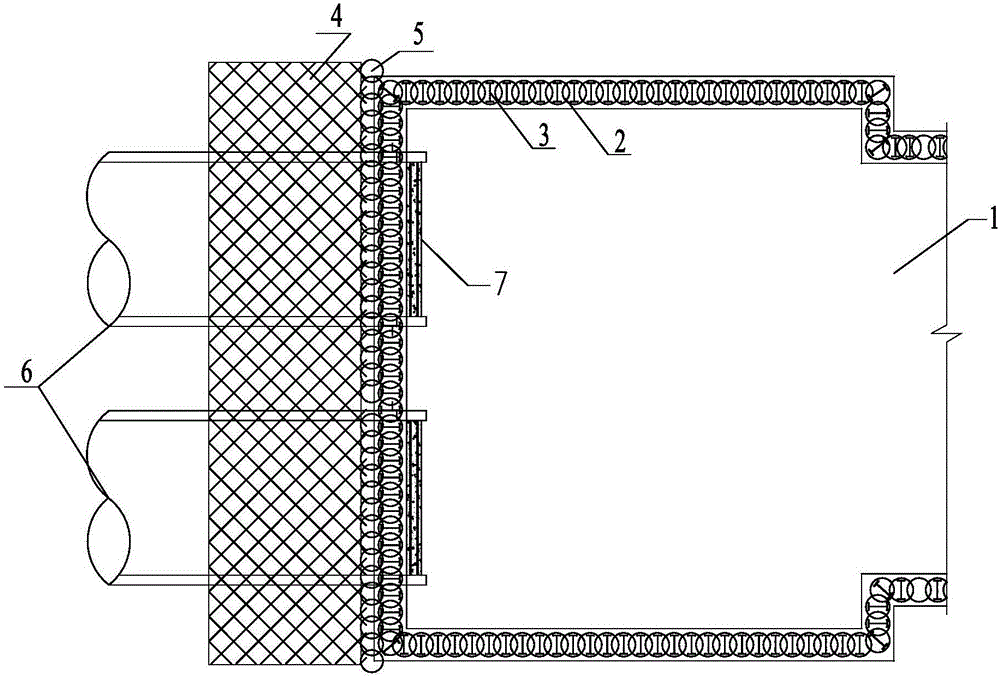

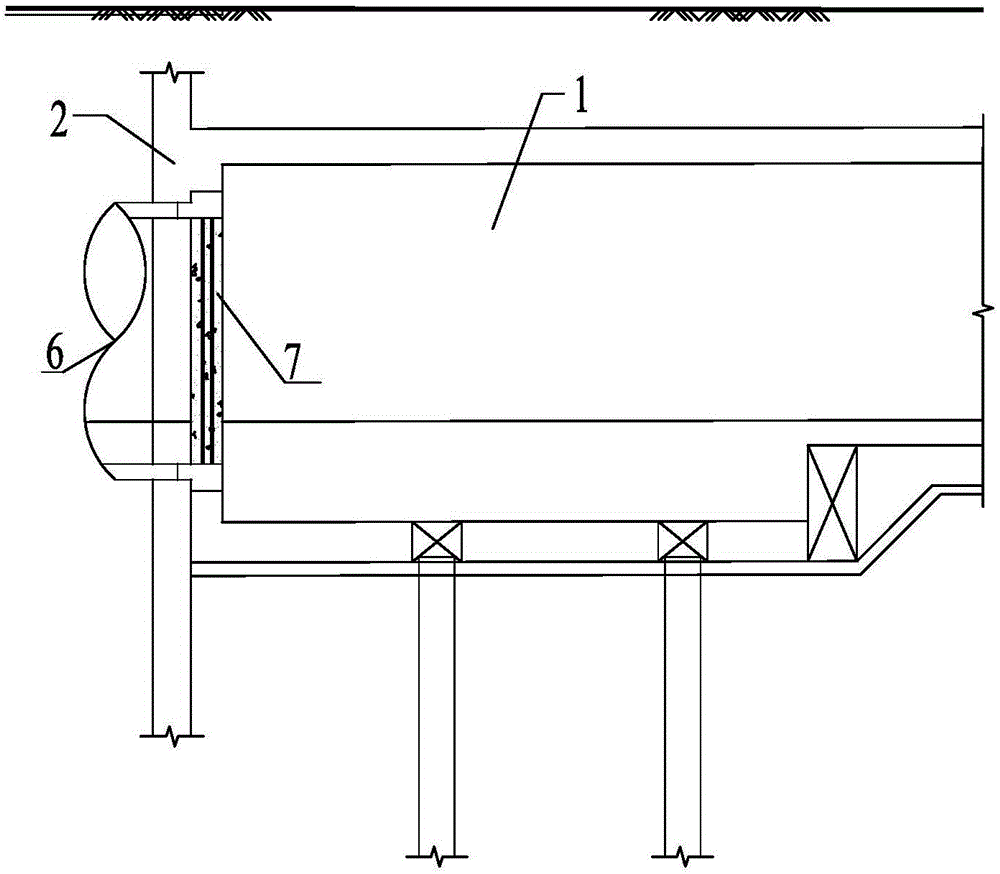

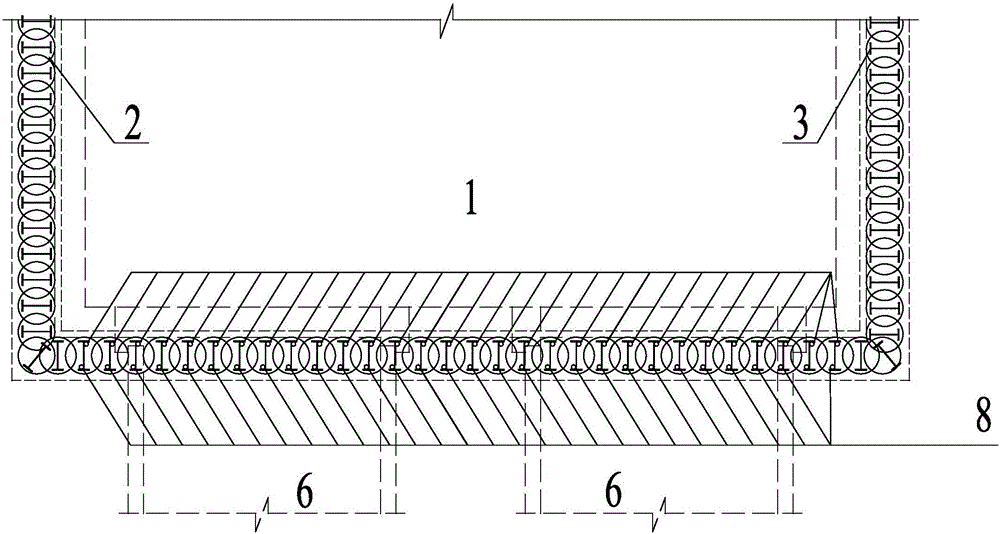

[0032] Embodiment: In this embodiment, Station A of Metro Line 2 in a certain city is used as a single-story station, and the end well of the station adopts the SMW construction method pile enclosure structure. The depth of the foundation pit of the end well is 11.9m, and the pile length is 21.4m. The insertion depth of the H-shaped steel for construction method piles is 9.6m, and the insertion ratio is 0.81. The reinforcement scheme of the end well adopts the combination of three-axis stirring pile and triple tube high-pressure jet grouting pile, and the reinforcement volume is 9m (width along the line direction) × 21.4m (length along the end wall direction) × 12.2m (depth). The west end well of Station A will be used as the U-turn and launching shaft of the shield machine of the construction unit of Station B. The main structure of the 70m end well of Station A will be capped at the end of July 2010, and the enclosing structure SMW construction method pile H-shaped steel is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com