Ceramic base used for electric appliance and manufacturing method of ceramic base

A manufacturing method and a technology for a ceramic seat, which are used in ohmic resistance heating parts, heating elements, heating element materials, etc., can solve problems such as unsatisfactory thermal conductivity, and achieve the effect of excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

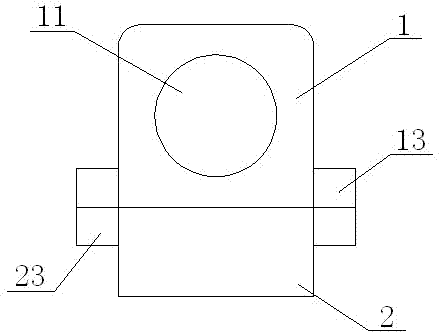

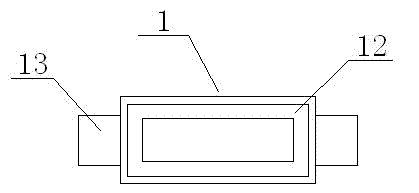

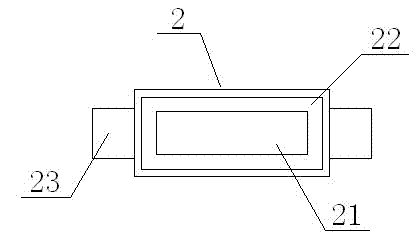

[0017] see Figure 1-Figure 3 As shown, embodiments of the present invention include:

[0018] A ceramic seat for electrical appliances, which is used for liquid electric mosquito coils and plays the role of insulation and heat conduction, comprising: a ceramic sleeve 1, and a base 2 matched with the ceramic sleeve 1, the ceramic sleeve 1 and the ceramic sleeve 1 The base 2 is made of ceramic material, and the outer surfaces of the ceramic sleeve 1 and the base 2 both contain an insulating and heat-conducting adhesive film layer;

[0019] The ceramic bushing 1 is a square bushing, the center of which is provided with an installation hole 11 matc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap