A crane component and its linkage connection device

A connecting device and crane technology, applied in the direction of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problem of low connection efficiency, achieve the effect of improving connection efficiency and realizing automatic linkage connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

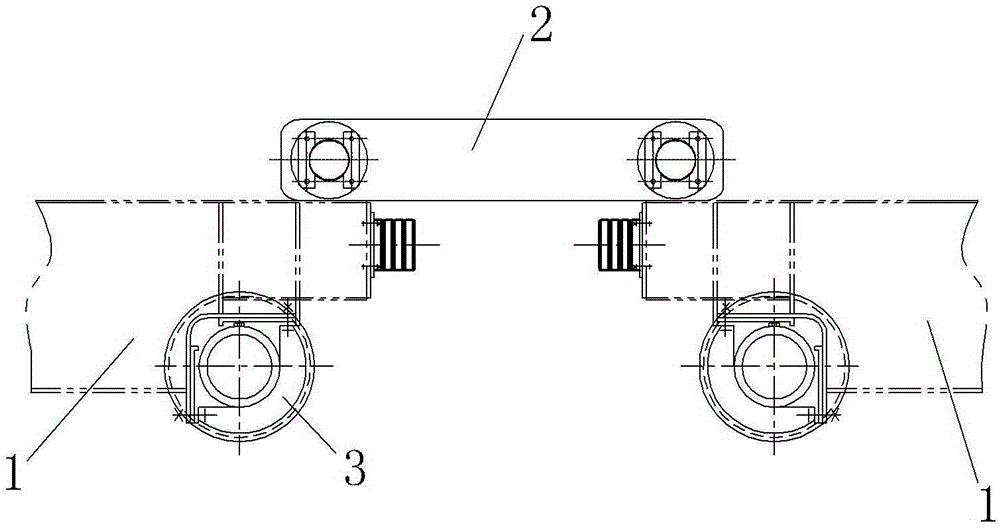

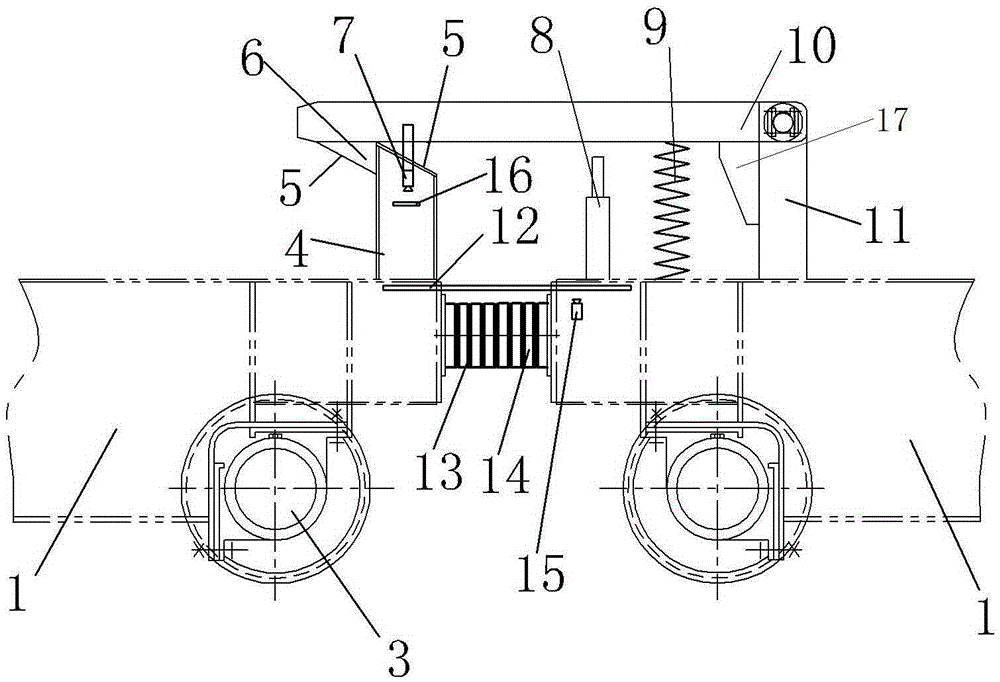

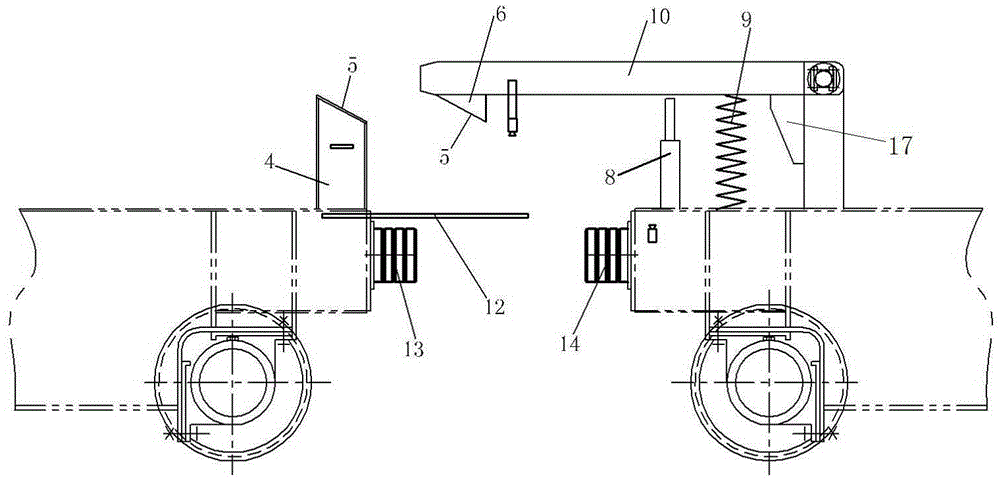

[0028] An implementation example of a crane assembly Figure 2~7 Shown: Including linkage connection device and two cranes arranged in the front and rear direction, each crane includes a main beam (not shown in the figure) extending in the left and right direction and end beams 1 arranged at both ends of the main beam, on the end beams A walking wheel 3 is provided, and the end beam in this embodiment is also called a walking beam. The linkage connecting device includes a bracket 11 and a block 4 respectively welded and arranged on the walking beams of two cranes. The bracket 11 is located on the front side of the block 4, and a swing rod 10 that can swing up and down is hinged on the bracket. It has a hook 6 which has a hook working position that is matched with the rear side of the stopper during the swinging process of the swing rod 10. A spring 9 is provided between the swing rod 10 and the walking beam at the front position. The upper end of the spring 9 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com