Steel pipe hoisting method used in hole-pile method steel tube column construction

A hoisting method and technology of steel pipe columns, which are applied in the field of steel pipe hoisting construction of steel pipe columns by hole pile method, can solve the problems of difficult movement of gantry frames, long transfer lines, and high safety risks, so as to improve overall stability and speed up construction Progress, the effect of improving the efficiency of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Hole pile method steel pipe column hoisting construction

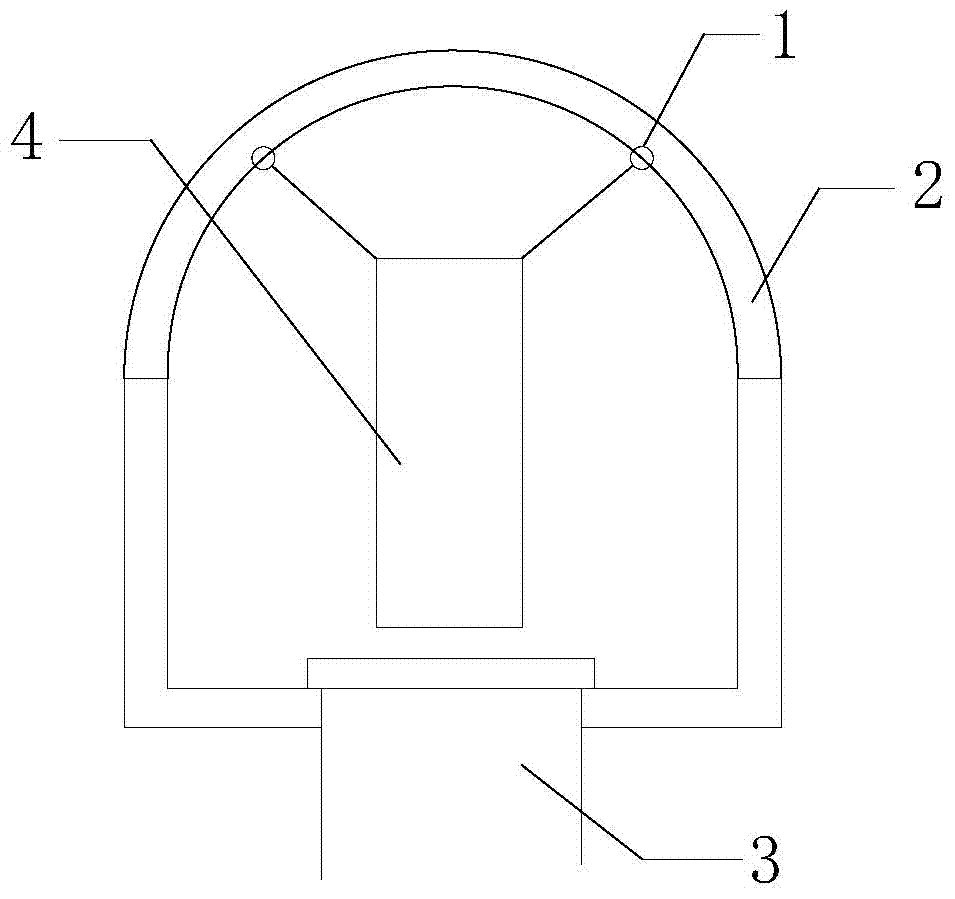

[0039] like figure 1 As shown in Fig. 1, the primary support 2 grid main reinforcement of the pilot tunnel is used as the temporary lifting point 1, and two lifting points are set up. The lifting points are longitudinally and symmetrically arranged on both sides of the center line of the steel pipe column, and horizontally symmetrically arranged on both sides of the pilot tunnel centerline. The lifting rings are directly locked. On the main reinforcement of the initial support grid in the pilot hole, adjust the center of the steel pipe column 4 by adjusting the chain length of the electric hoist during hoisting, so that the steel pipe column coincides with the central axis of the vertical hole 3. The steel pipe column is hoisted downward by the gourd. During the hoisting process, the multi-line symmetrical hoist is used to adjust and limit the verticality. The hoisting method is convenient to set ...

Embodiment 2

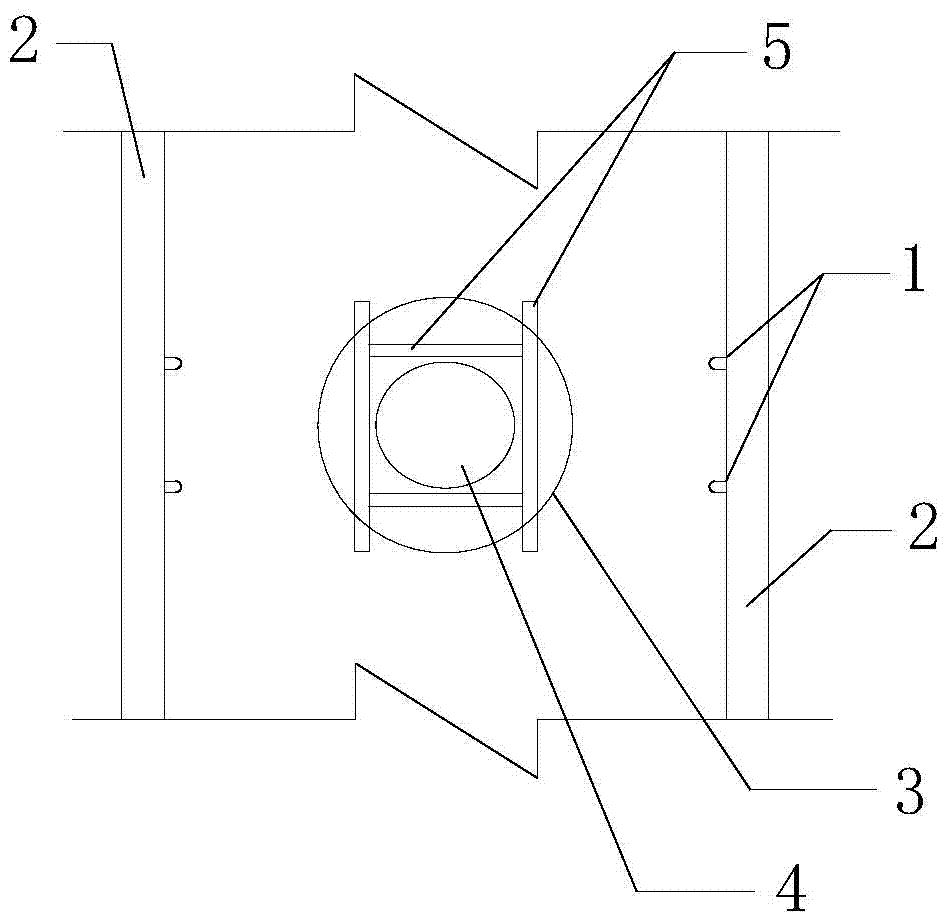

[0045] For the hoisting construction of the steel pipe column by the hole pile method, the main reinforcement of the initial support grid of the pilot tunnel is used as a temporary lifting point, and a total of four lifting points are set. The lifting ring is directly stuck on the main reinforcement of the primary support grid of the pilot tunnel, and the center of the steel pipe column is adjusted by adjusting the chain length of the electric hoist during hoisting. The steel pipe columns are hoisted downward by electric hoists, and the columns are connected with high-strength bolts. After the hoisting is completed, a detachable I-shaped steel well frame 5 is used to limit the steel pipe column.

[0046] Preferably, the distribution structure of the I-shaped steel well-shaped frame is: two of the I-shaped steels tighten the initial support of the pilot hole under the premise of clamping the steel pipe column, and the other two are fixed on the above-mentioned two under the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com