Stepped conical nut fastener

A technology of fasteners and steps, which is applied in the field of step cone nut fasteners, can solve the problems that bolts and expansion sleeves can only stay on the attachments, unfavorable installation of fastened objects, waste of materials, etc., and achieve strong adhesion , good versatility, and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

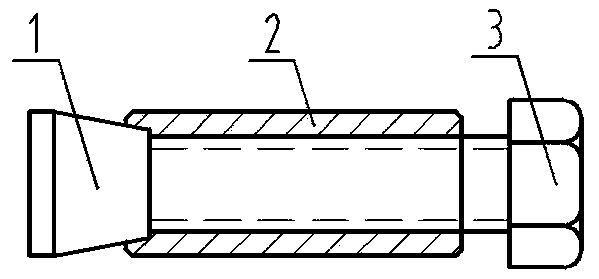

[0009] The stepped cone female fastener of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0010] Referring to the accompanying drawings, the stepped cone female fastener of this embodiment is made of metal, and the stepped cone female fastener includes a stepped cone nut 1, an expansion sleeve 2 and a bolt 3, and the stepped cone nut 1 is provided with The inner thread has a step at one end to strengthen the adhesion, and the other end is tapered; the stepped conical nut 1 is connected to the inner hole of the expansion sleeve 2, and the bolt 3 passes through the inner hole of the expansion sleeve 2 and the stepped conical The inner thread of the conical end of the nut 1 is butted, and by rotating the bolt 1, the stepped conical nut 1 translates to the inner wall of the expansion sleeve. Peripheral wall, to achieve fastening connections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com