Insulation pillar cleaning device

A technology for insulating pillars and cleaning devices, which is applied to cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of affecting power supply, complicated operation, and long time consumption, and achieve the effect of saving cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

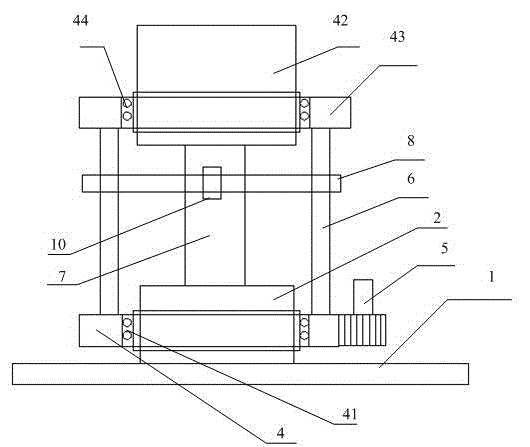

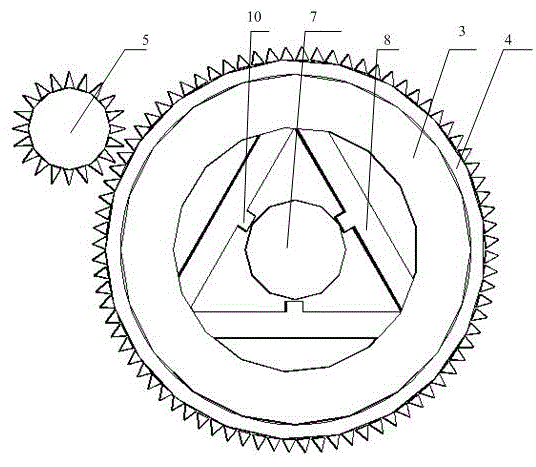

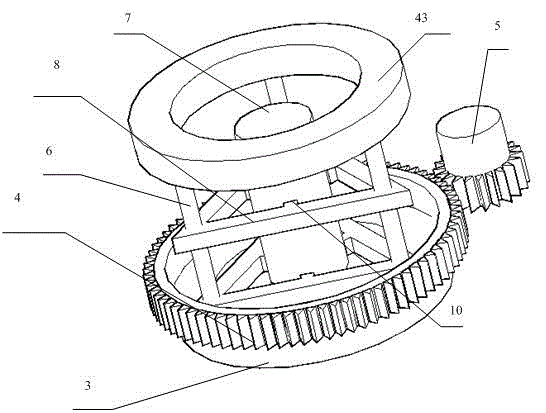

[0024] Such as Figure 1-Figure 4 shown.

[0025] The insulating support cleaning device comprises a turntable 3 coaxial with the insulating support 7, a gear turntable 4, and an upper turntable 43. The upper end of the insulating support 7 is provided with an upper base 42 of the insulating support, and the lower end of the insulating support 7 is provided with a lower base 2 of the insulating support. 4 is set on the outer diameter of the turntable 3, the output shaft gear of the motor 5 meshes with the gear of the gear turntable, the turntable 3 is socketed with the lower base 2 of the insulating support through the lower bearing 41, and the upper turntable 43 is connected with the upper base of the insulating support through the upper bearing 44. The base 42 is socketed, and at least three vertical columns 6 are arranged between the upper end surface of the turntable 3 and the lower end surface of the upper turntable 43; adjacent vertical columns 6 are connected by a horiz...

Embodiment 2

[0035] On the basis of above-mentioned embodiment:

[0036] Such as Figure 5-Figure 7 As shown, it also includes oblique pressure screw 11, which runs through the transverse column 8, and the wiper block 10 is installed on the front end of the oblique pressure screw 11, and the front end of the oblique pressure screw 11 is located between the transverse column 8 and the insulating support 7. At one end, the angle between the axis of the baroclinic screw 11 and the transverse column 8 is an angle A, and the value range of the angle A is less than or equal to 60 degrees.

[0037] By adopting the above-mentioned oblique pressure screw 11 and the value range of the above-mentioned included angle A, the wiping block 10 can be made to contact the outer diameter surface of the insulating support in an oblique manner, so that the cleaning effect is optimal. Generally, the included angle A can be set to 40 degrees or 30 degrees or 15 degrees. If the included angle A is 90 degrees, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com