A transmission device for laser cutting

A laser cutting and conveying device technology, which is applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as fault improvement, and achieve the effects of reducing faults, avoiding forehead damage, and reducing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

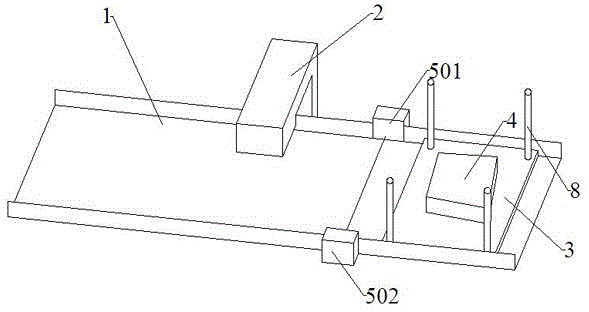

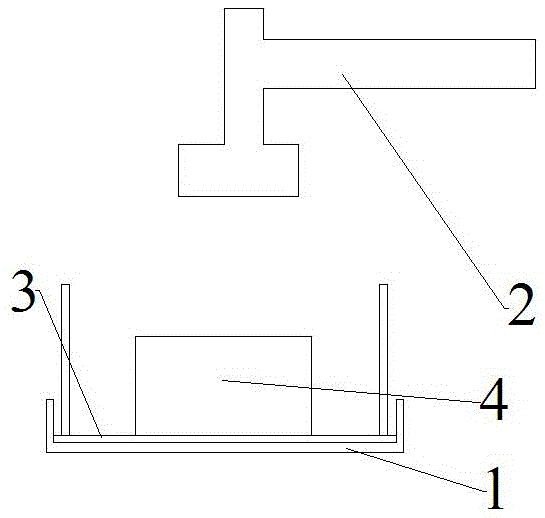

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0018] A conveying device for laser cutting, comprising an object to be cut 4, a conveying belt 1, a laser cutter 2 and a control device for controlling the laser cutter. The laser head of the laser cutter 2 can be manually adjusted in position.

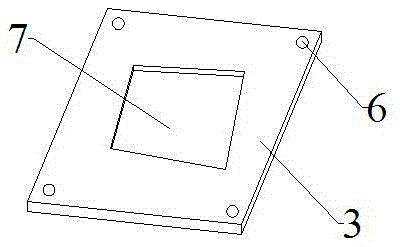

[0019] A storage board 3 is also arranged on the conveyor belt 1 . In order to facilitate the quick placement of the storage board 3 on the conveyor belt 1 , baffles are provided on both sides of the conveyor belt 1 . The storage board 3 is set as a rectangle, and the width of the conveyor belt 1 is the same as that of the storage board 3, so that the storage board 3 can be directly and quickly placed on the conveyor belt 1 when in use, and there are baffles on both sides to prevent the storage board from being skewed up.

[0020] A groove 7 is arranged on the object board 3 , and the shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com