Lever synchronizer

A synchronizer and lever technology, which is applied in the field of auto parts, can solve the problems of bloated structure, the inability to return the gear sleeve 1 normally, and the long axial arrangement of the gearbox.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

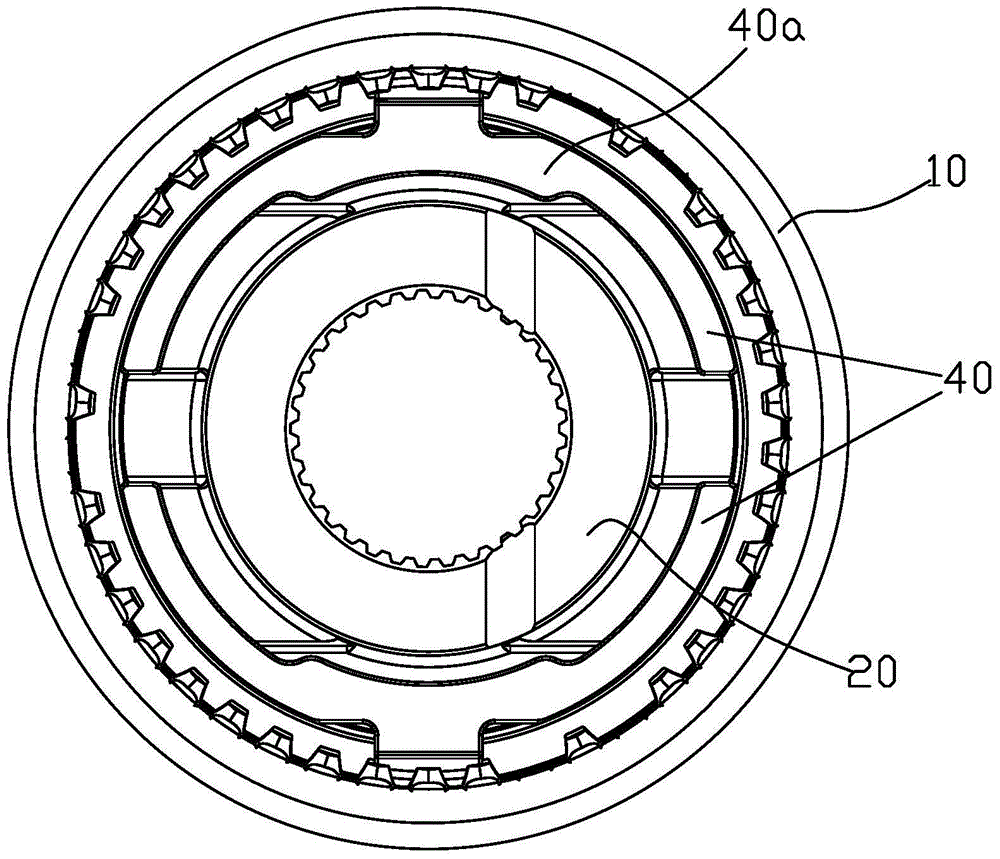

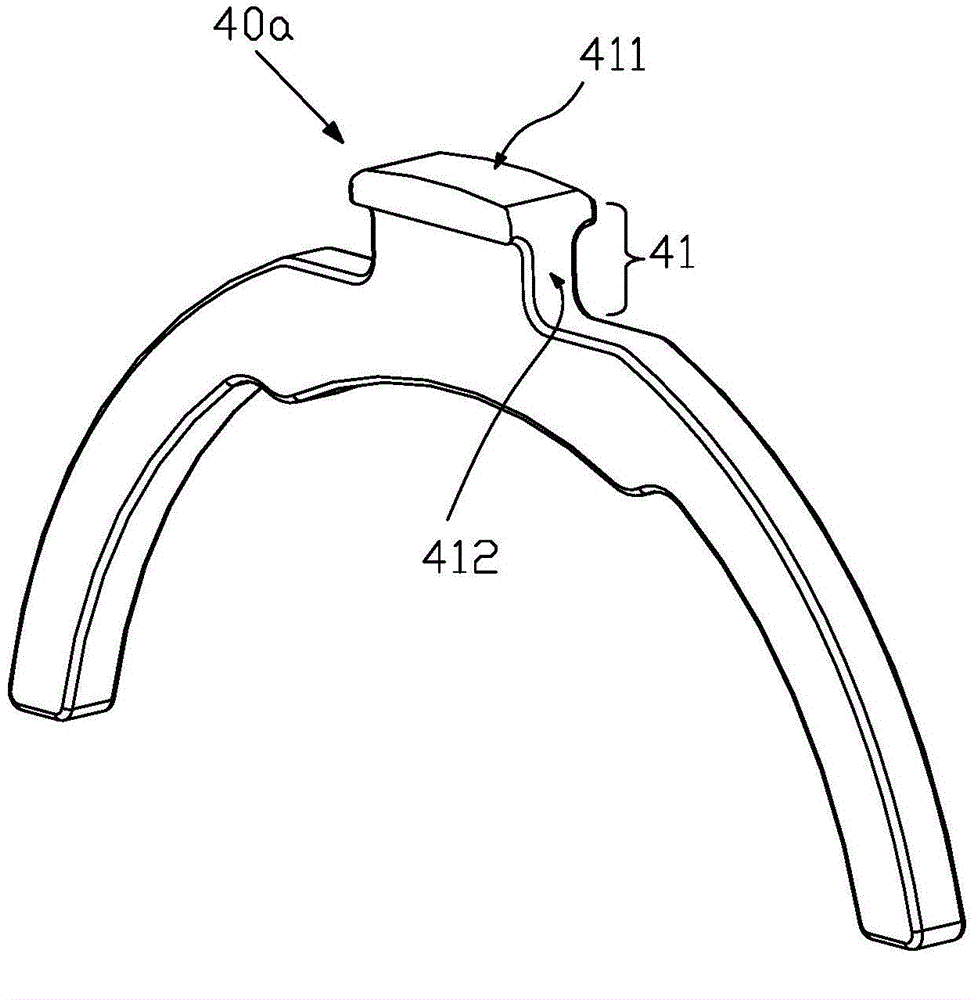

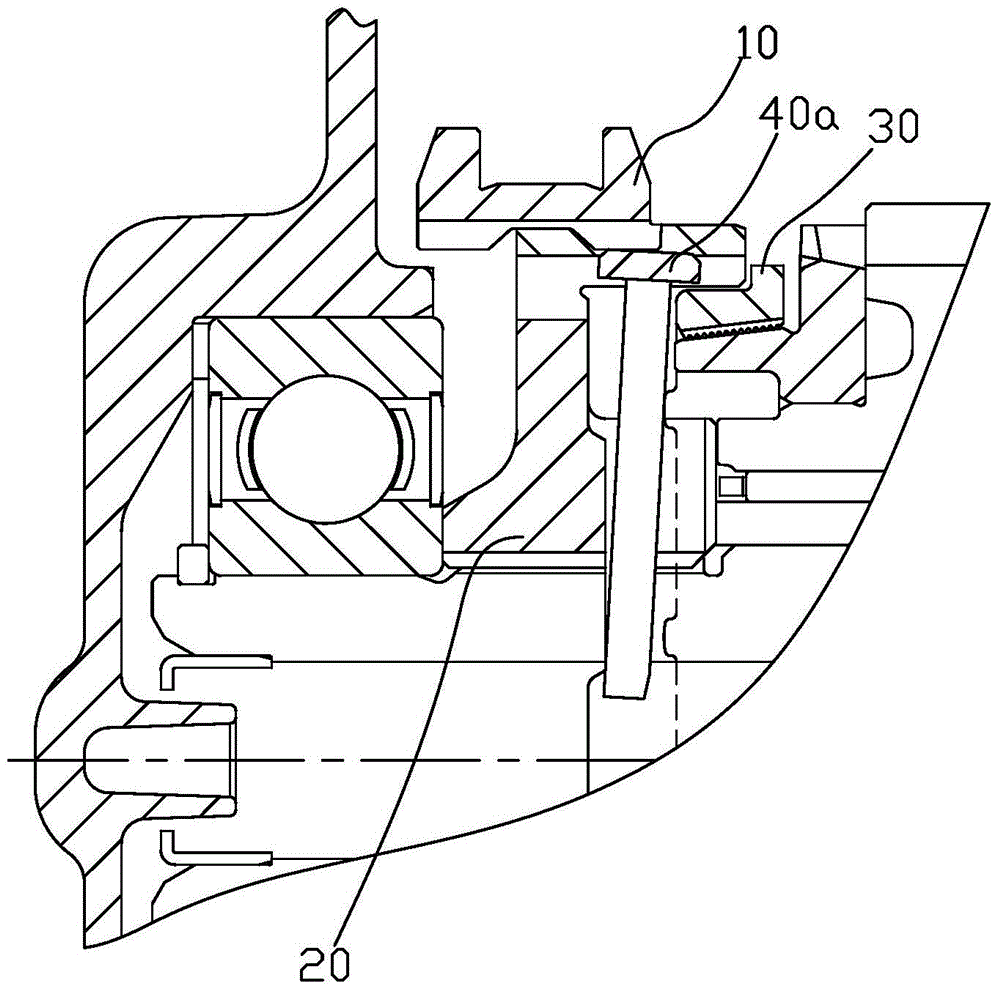

[0013] Such as Figure 1-3 As shown, a lever synchronizer includes a gear sleeve 10, a gear hub 20 and a synchronizing ring 30, a lever 40 is arranged between the gear hub 20 and the synchronizing ring 30, and the described lever 40 consists of two semicircular The lever unit 40a is composed of two semicircular lever units 40a with opposite openings. The arc-shaped top of the lever unit 40a is provided with a boss 41, and the top of the boss 41 is clamped between the gear sleeve 10 and the gear hub 20. Meanwhile, the boss top surface 411 where the boss 41 is in contact with the gear sleeve 10 extends to both sides along the axial direction of the gear sleeve 10 so that the axial section of the boss 41 is T-shaped. The openings of the two lever units 40a are arranged opposite to each other and respectively clamped in the annular grooves on the gear hub 20. The annular grooves of the gear hub 20 provide a fixed point for the lever unit 40a, which is the fulcrum of the lever unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com