Highly-sealed ball valve

A high-sealing, ball valve technology, used in valve devices, pipes, cocks including cut-off devices, etc., can solve the problems that the sealing ring or sealing block cannot withstand high temperature, the sealing is not strict, and the production is affected, so as to achieve good sealing, Good sealing coordination and good overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

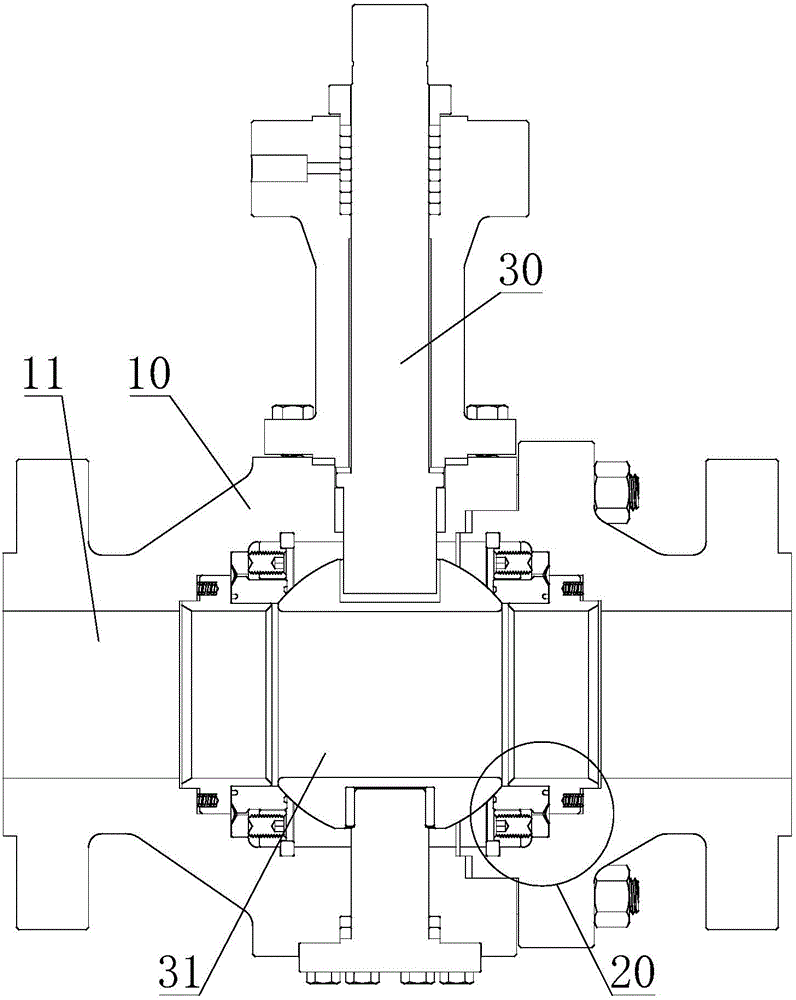

[0012] Example, see Figure 1 to Figure 4 As shown: a high-sealing ball valve includes a main valve body 10 with a passage 11 passing through the main valve body 10. The middle of the passage 11 is provided with a valve seat assembly 20, and the middle of the passage 11 is provided with a rotatable valve stem 30. A ball 31 matched with the valve seat assembly 20 is fixed on the valve stem 30. That is, the sphere 31 closely fits with the sealing surface of the valve seat assembly 20, so as the valve stem 30 rotates, the sphere 31 follows the rotation, so that the overlap between the through hole of the sphere 31 and the passage 11 is determined by 0-100% change, and then realize the cut-off and penetration of the channel 11.

[0013] The valve seat assembly 20 may be two groups located on both sides of the ball 31. The following takes the group located on the right side of the sphere 31 as an example for description.

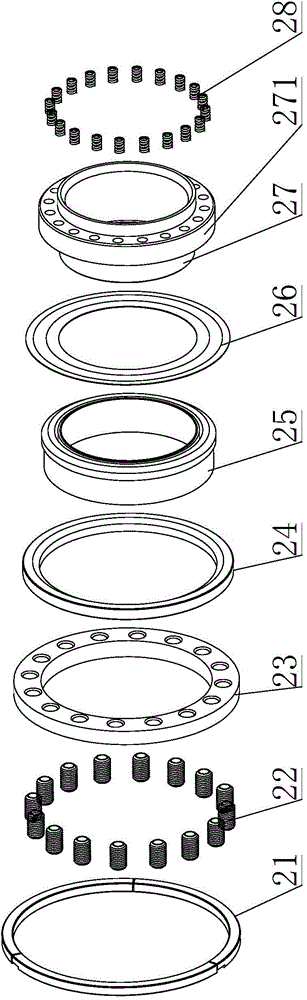

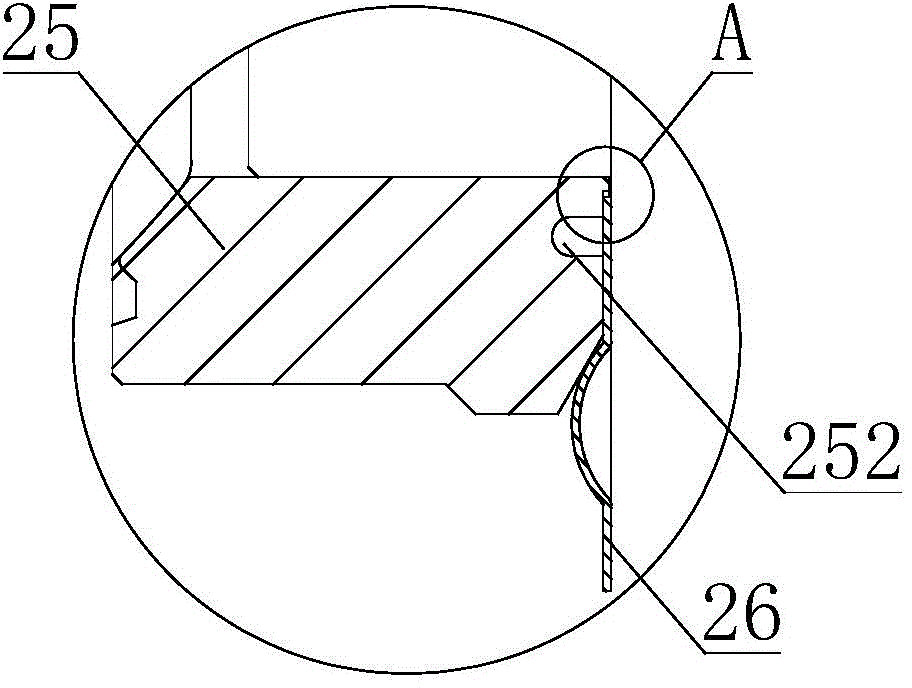

[0014] The valve seat assembly 20 includes a hard-seal valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com