A slurry spraying device for dry-process papermaking reconstituted tobacco production

A spraying device and dry papermaking technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of poor atomization effect, easy nozzle blockage, poor adjustability, etc., and achieve good atomization effect, uniform spraying, and high flow rate stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

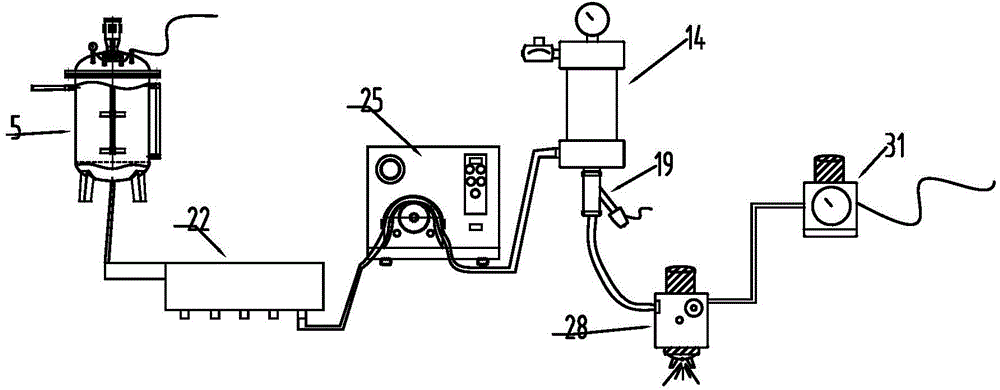

[0033] Such as image 3 The slurry spraying device shown includes a constant pressure storage tank 5, a slurry distributor 22 connected to the material outlet of the constant pressure storage tank 5, the slurry distributor 22 has a plurality of slurry outlets 24, Each slurry outlet 24 is connected to a slurry buffer 14 through a metering pump 25 respectively, and the slurry buffer 14 is connected to a slurry inlet 29 of a binary nozzle 28 through a shut-off valve 19 . The binary nozzle 28 has a slurry inlet 29 and a compressed air inlet 30 for mixing compressed air and slurry. In addition, a compressed air pressure regulating valve 31 is connected to the compressed air inlet 30 through a pipeline to provide compressed air to the binary nozzle 28 .

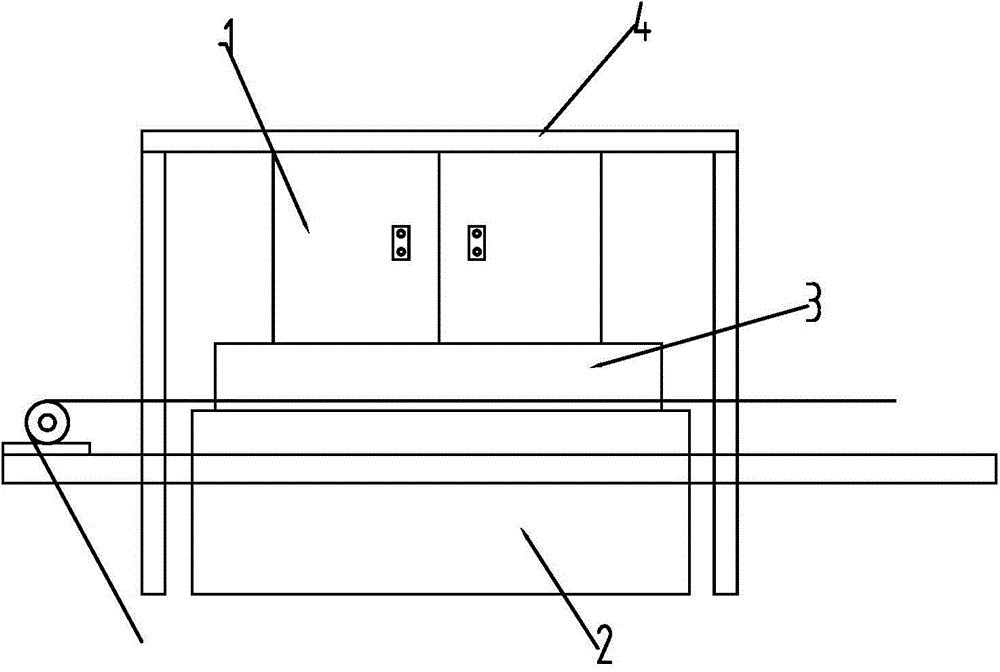

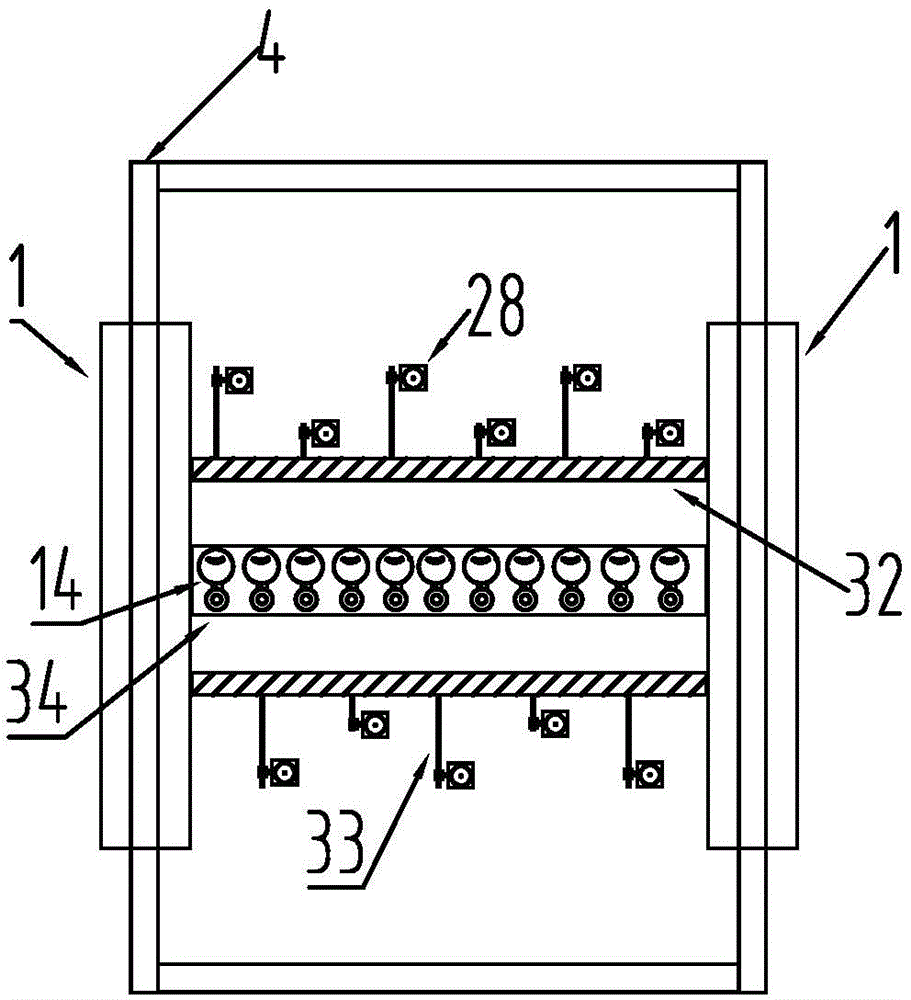

[0034] Among them, such as figure 1 with 2 As shown, the main body of the slurry spraying device is installed on the frame 4 . Mounting boxes 1 are arranged on both sides of the frame 4, and the constant pressure supply storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com