Bell-less material distributing method capable of ensuring stable running of blast furnace

A blast furnace and cloth technology, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of frequent wind breaks, narrow local coke window, collapse and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

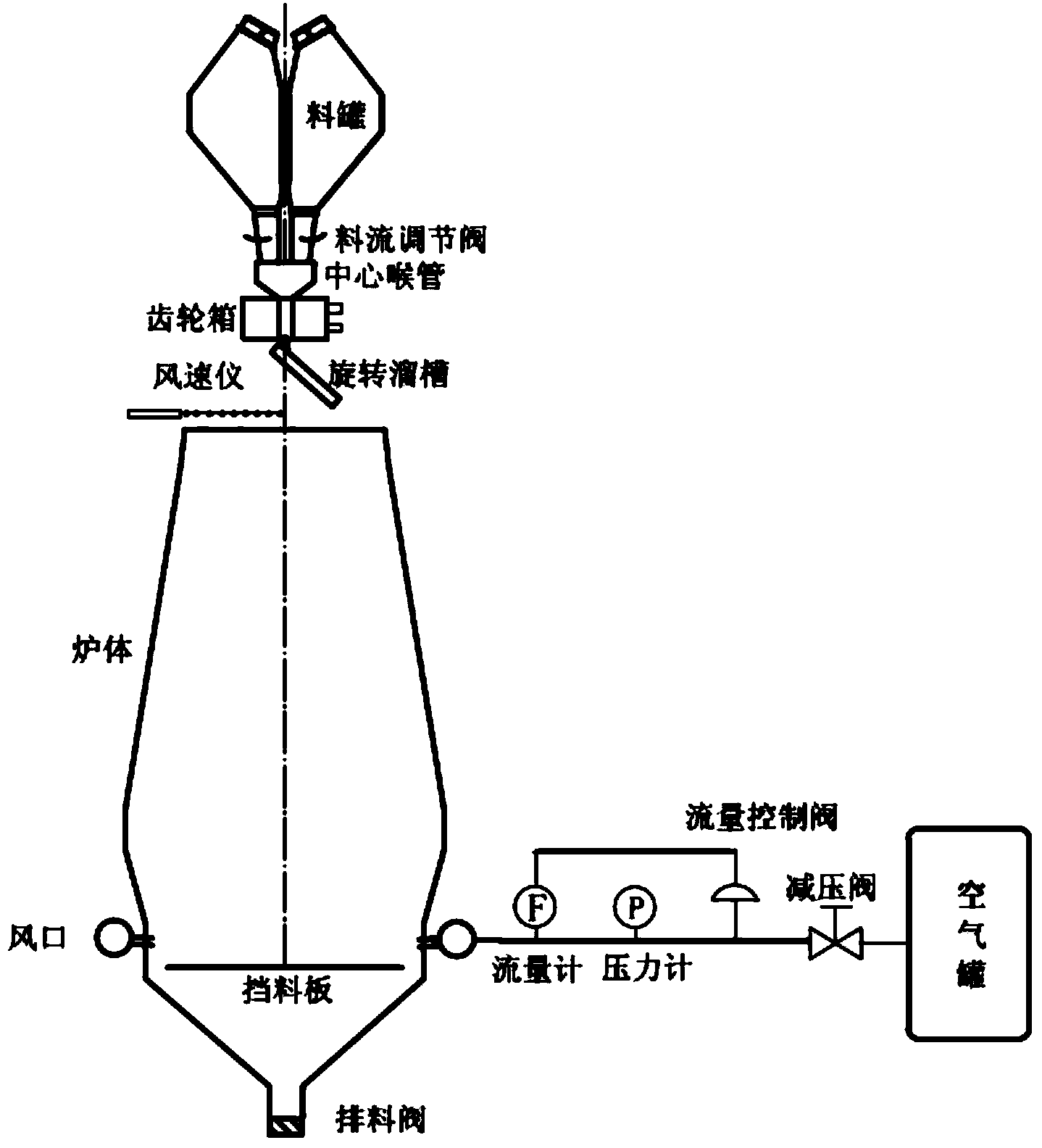

Method used

Image

Examples

Embodiment 1

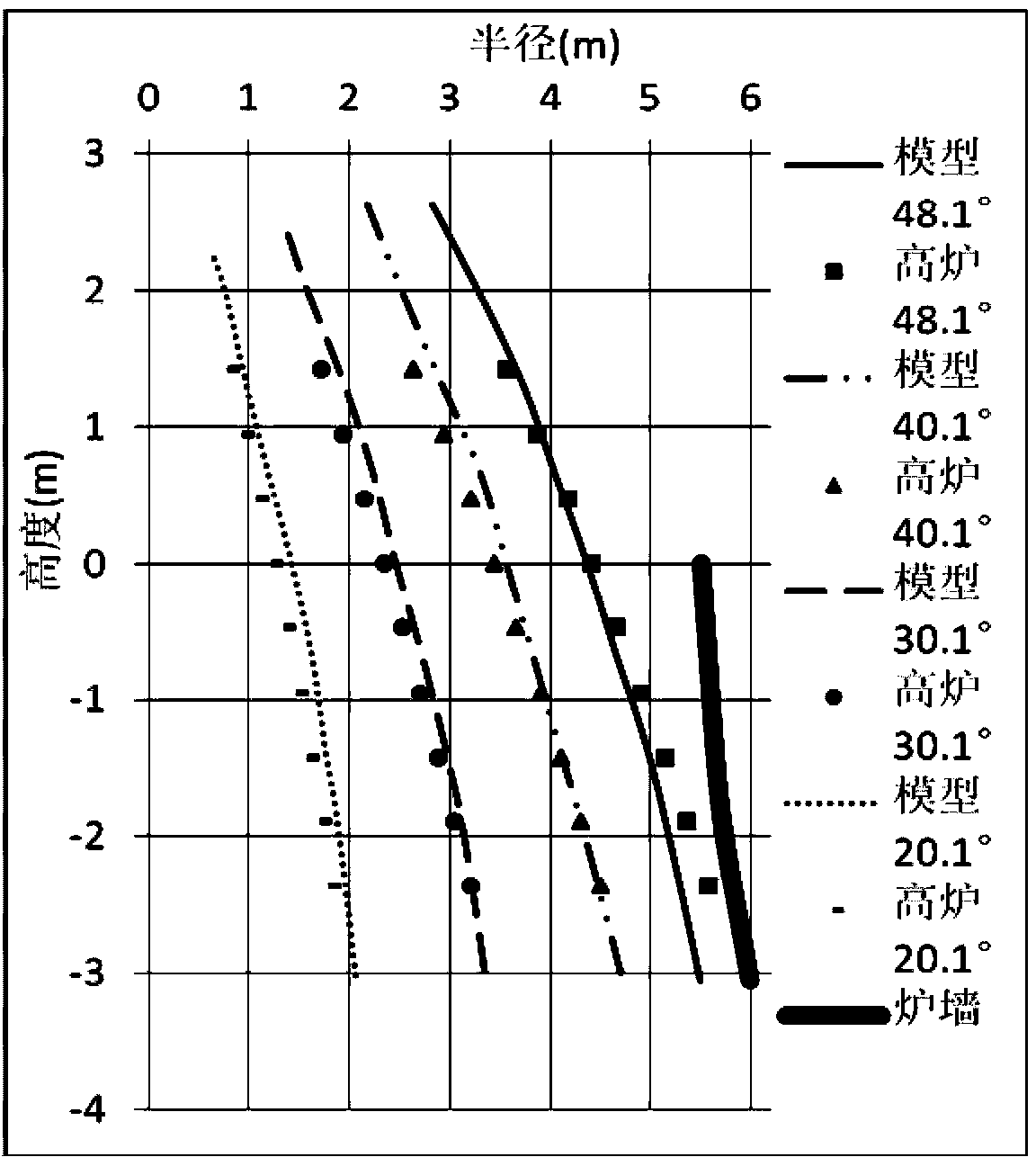

[0036] Embodiment 1: Carry out the practice of protecting the weak zone in the middle of the coke layer on the cold cloth model.

[0037]

[0038]

[0039] The operating parameters of the blast furnace are set as: top gas flow rate 1.0m / s, coke batch 32t, ore batch 170t, material line 1.6m, based on the distribution matrix A of Shagang 5800 blast furnace in July 2013, optimize from A to F :

[0040] Gradually reduce the number of circles at the center and edge of the coke, for example, the 5 circles and 4 circles of the 1st and 2nd gears of the coke are reduced to 4 circles and 3 circles respectively, and the 12th gear of the coke is reduced from 3 circles to 2 circles;

[0041] Gradually spread the ore further, and gradually increase the ore from 5 stalls to 8 stalls;

[0042] Increase the number of turns of coke in the middle part, that is, increase the 4th, 5th, and 6th gears in the middle part from one turn to 3 turns each.

[0043] According to the matrix from A t...

Embodiment 2

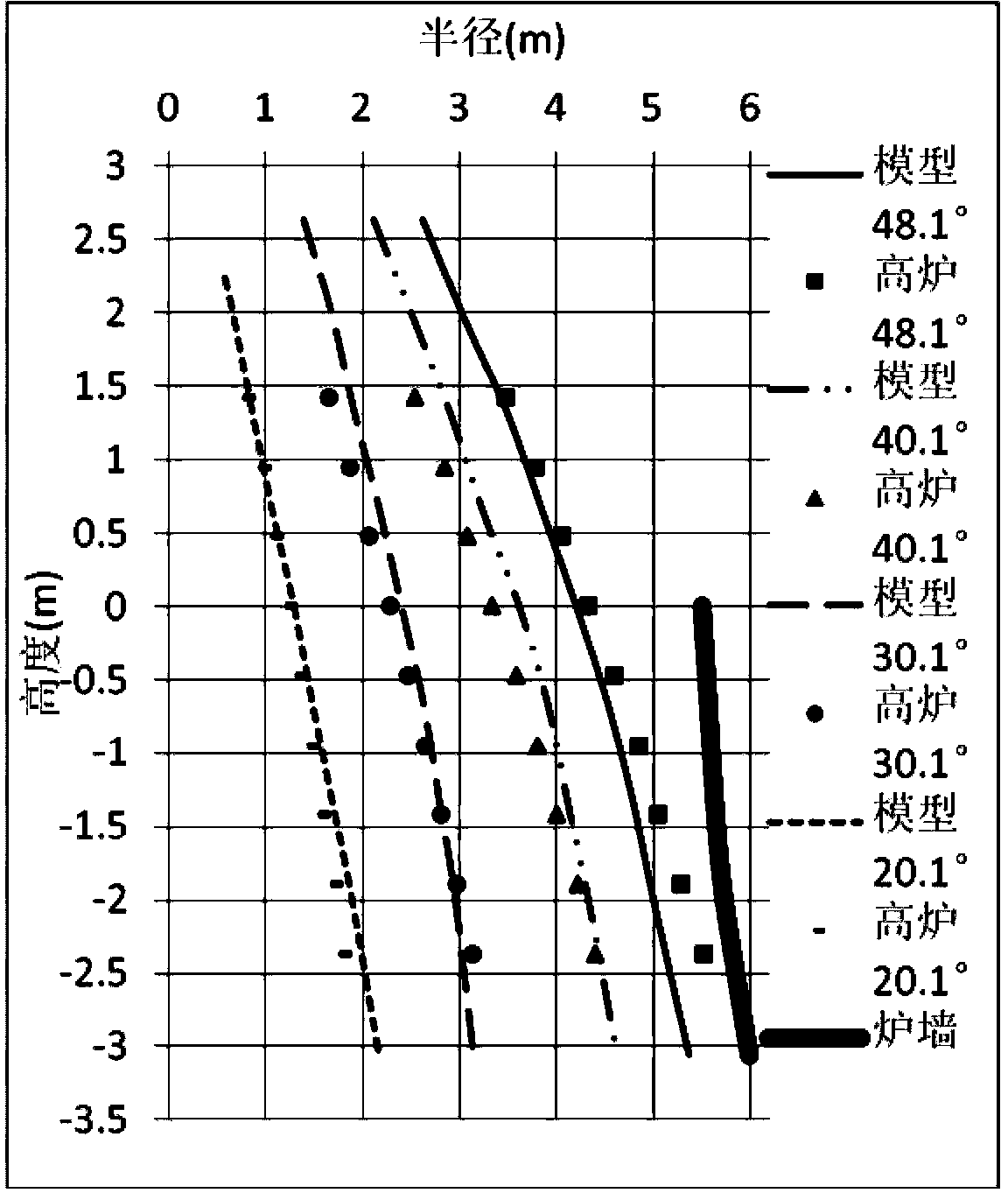

[0044] Example 2: The practice of protecting the weak zone in the middle of the coke layer on Shagang 5800 blast furnace

[0045]

[0046] On July 23, 2013, Shagang 5800 blast furnace began to implement the cloth attempt to protect the weak zone in the middle of the coke layer. The operation from June 10, 2013 to July 22, 2013 was called the first stage. The September 12, 2013 operation was called phase two. And from June 10, 2013 to September 12, 2013, there was no significant change in the quality of raw materials and fuels, so the impact of changes in the quality of raw materials and fuels on blast furnace operation during this period can be ruled out, such as Figure 10 shown.

[0047] A typical cloth matrix for the first stage is The average coke batch is 30.1t, the average ore batch is 157.2t, the total number of coke turns is 22, the total number of ore turns is 22, and the top gas flow rate is 1.0m / s. It can be calculated from the cloth matrix setting that the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com