Spring rubber seismic reduction and isolation system of bridge

A shock-absorbing and isolating rubber technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of affecting the safety and comfort of driving on bridges, the inability to effectively eliminate earthquakes, and the high cost of shock-absorbing and isolating systems. It is easy to achieve Prefabrication and assembly, easy setup, effect of reducing horizontal shear displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

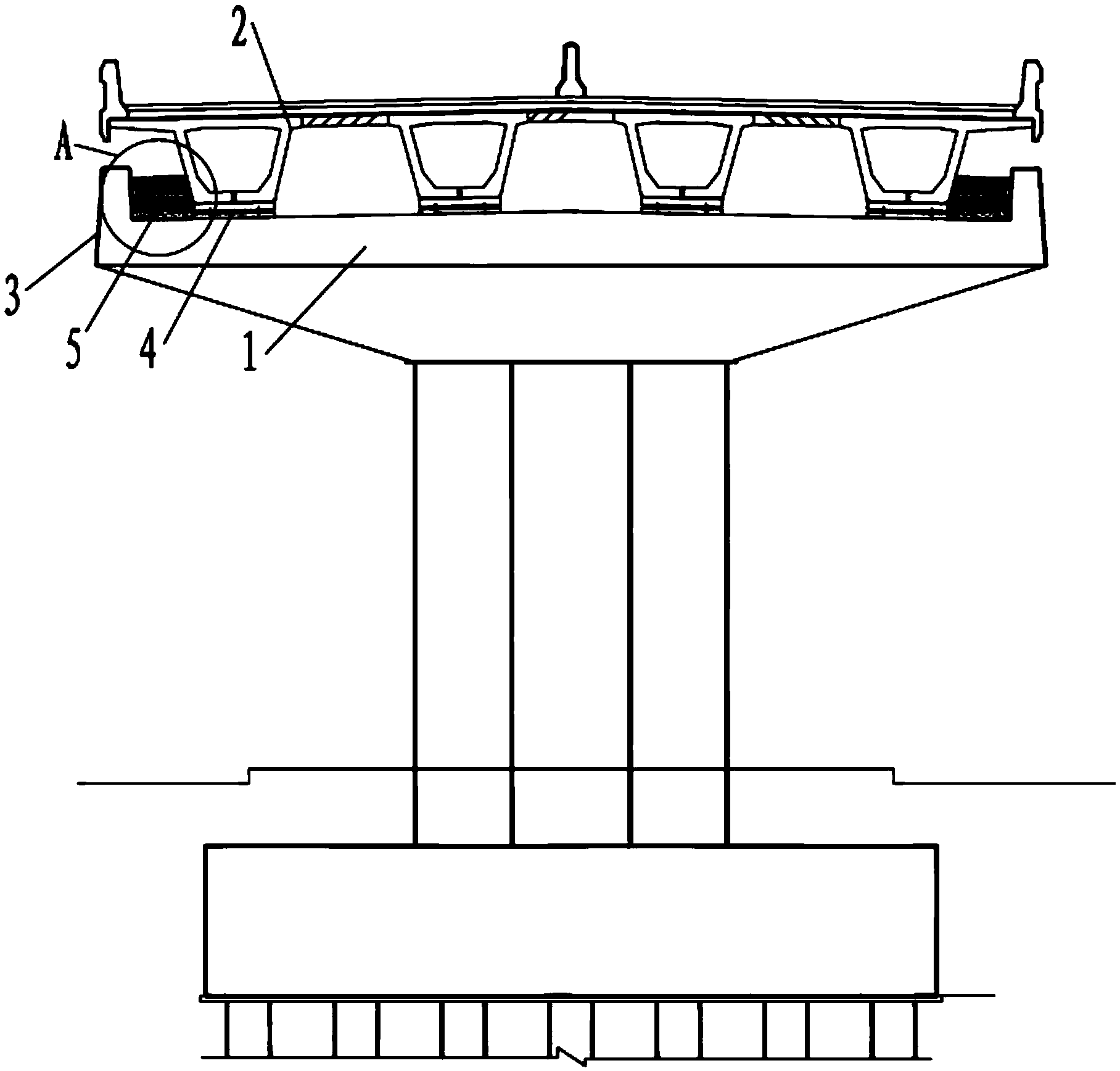

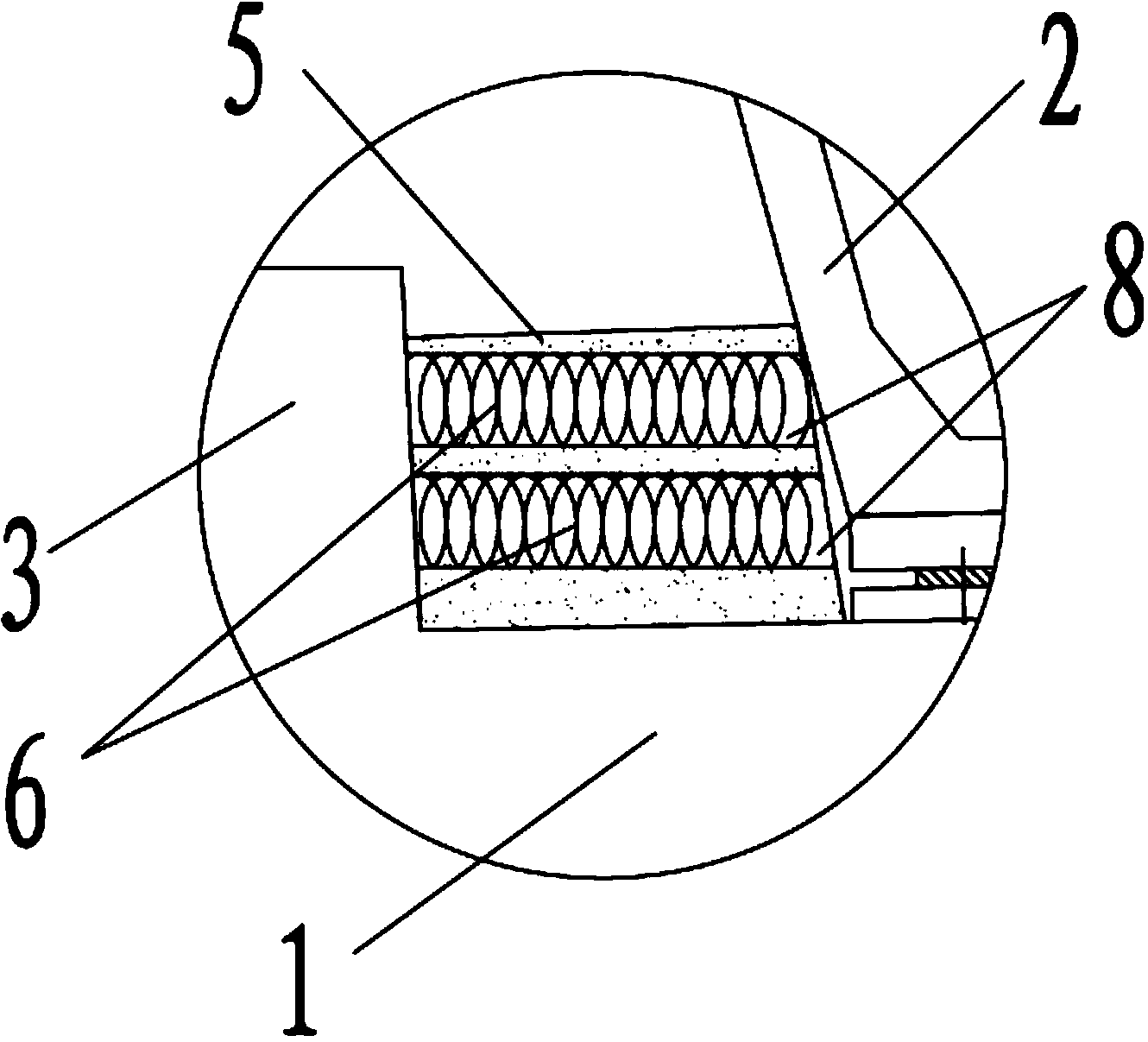

[0020] Such as figure 1 As shown, a spring rubber shock-absorbing and isolation system for a bridge in this embodiment includes a cover beam 1 and a beam body 2. Both ends of the cover beam 1 extend upward to form a stopper 3, and between the two stoppers 3 The top surface of the cover beam 1 is provided with a number of sliding friction bearings 4, the beam body 2 is stacked on the top of the cover beam 1 through the sliding friction bearings 4, and there is a gap between the beam body 2 and the stoppers 3 on both sides .

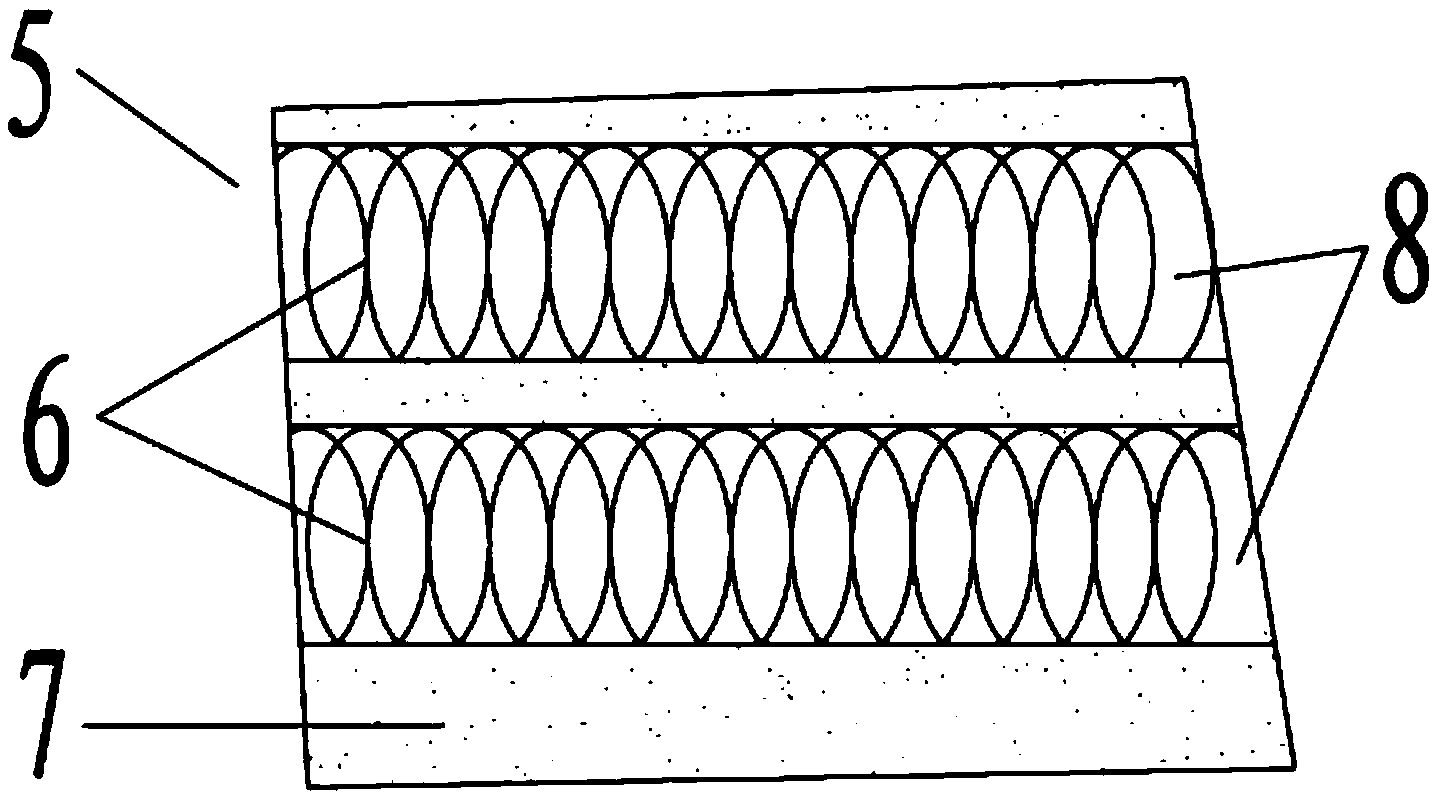

[0021] combine figure 2 As shown, the gap is filled with a spring rubber self-resetting spacer 5, the spring rubber self-resetting spacer 5 is a rubber block 7 with a spring 6 inside, and the two ends of the spring 6 are connected to the beam body 2 and the stopper respectively. on block 3.

[0022] Specifically, such as image 3 As shown, the rubber block 7 is horizontally provided with several through holes 8 for passing through the spring 6 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com