Automotive sound temperature calibration test device and automotive sound temperature calibration test method

A car audio and test device technology, applied to electrical components and other directions, can solve problems such as unfavorable comprehensive parameters, cumbersome test process, etc., and achieve the effect of simple operation and reliable test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

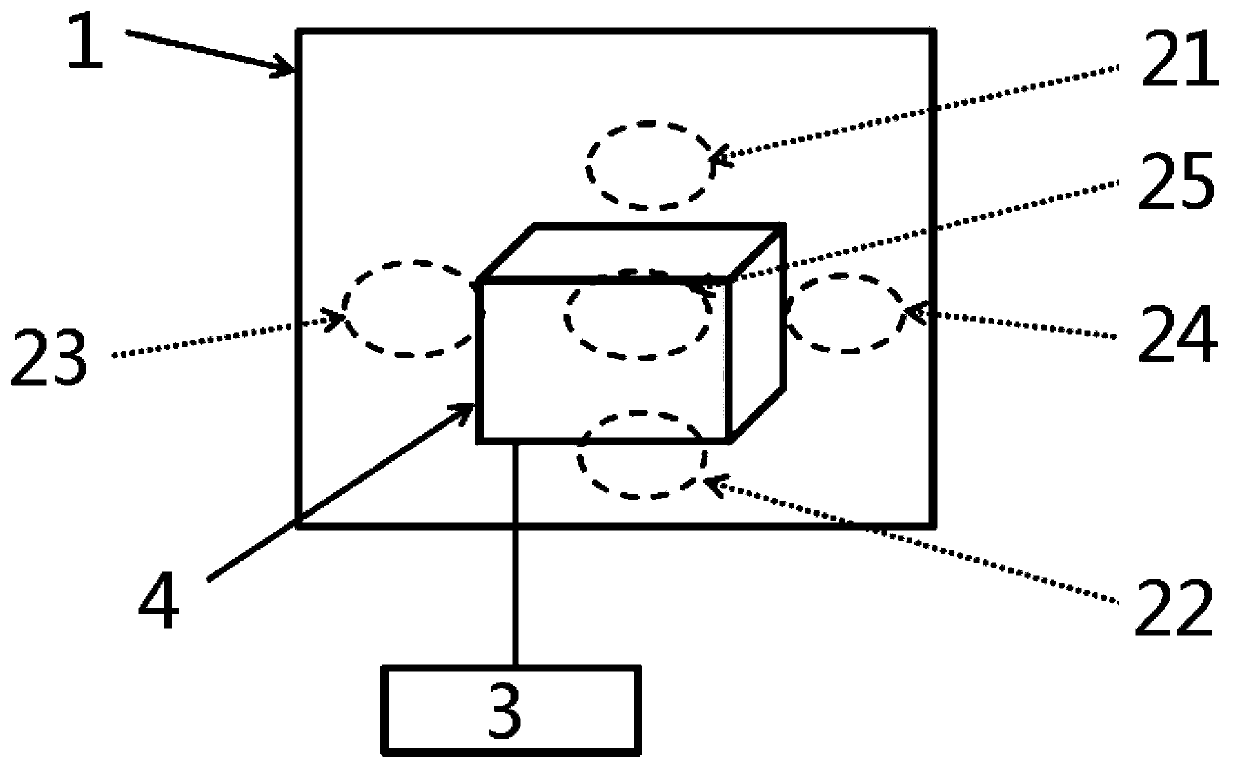

[0019] Such as figure 1 As shown, a car audio temperature calibration test device includes a temperature box 1, a fixing mechanism, a DC power supply 3, a temperature sensor and a temperature recorder. The rear of the car audio sample 4 is installed in the temperature box 1 through the fixing mechanism. There are 5 temperature sensors in total, including an upper sensor 21, a lower sensor 22, a left sensor 23, a right sensor 24 and a rear sensor 25, which are respectively arranged on the top, bottom, left, right and Rear, used to detect the real-time temperature of these locations. The temperature recorder is connected to each temperature sensor, and is used to record the real-time temperature collected by the temperature sensor to complete the temperature calibration. The temperature box 1 is provided with a wire hole, and the wire harness of the car audio sample 4 passes through the wire hole to connect to the DC power supply 3 .

[0020] In addition, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com