Process for preparing a functional fermented milk product and functional fermented milk product prepared therewith

A technology of fermented milk products and fermented milk, applied in the direction of dairy products, milk preparations, bacteria used in food preparation, etc., can solve the problems of undisclosed probiotics and unrevealed functional fermented dairy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

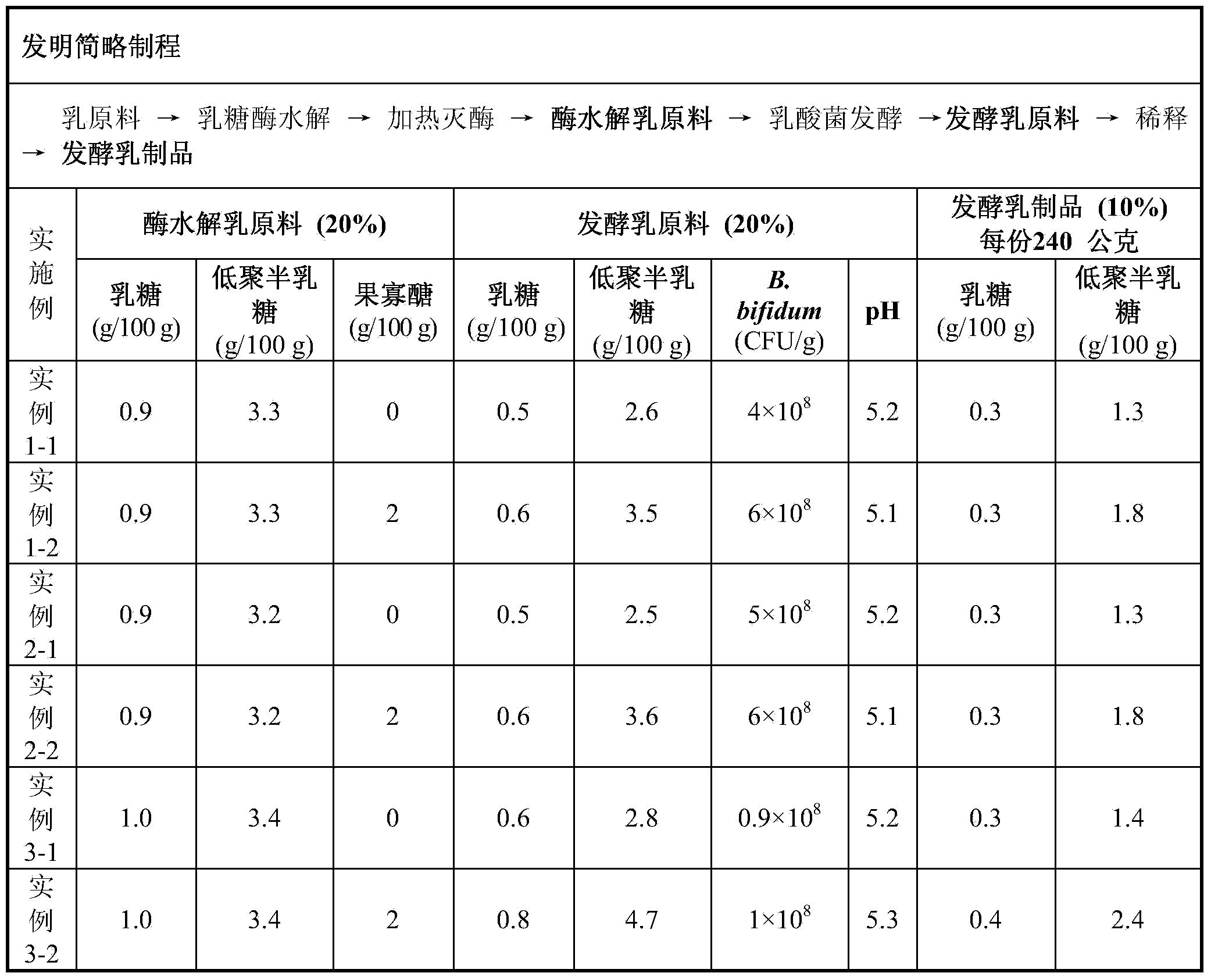

Method used

Image

Examples

example 1-1

[0047] Stir the milk powder evenly and dissolve it in water to form high-concentration milk (solid content is about 40%). Add lactose-decomposing enzyme at a rate of 0.1g lactose-decomposing enzyme per 100g lactose. After reacting for 60 minutes, heat it to 85-90°C. Inactivate enzymes. Dilute the high-concentration milk that has completed the enzyme reaction to a solid content of about 19.9%. The lactose content of the obtained enzyme-hydrolyzed milk raw material is 0.9 (g / 100g); the content of galacto-oligosaccharide is 3.3 (g / 100g). Add B.bifidum (3×10 6 (CFU / g)) was fermented at 37°C for 10 hours, and the lactose content of the obtained fermented milk raw material was 0.5 (g / 100g); the content of galacto-oligosaccharides was 2.6 (g / 100g); 8 (CFU / g), the final pH value is 5.2.

example 1-2

[0049] Stir the milk powder evenly and dissolve it in water to form high-concentration milk (solid content is about 40%). Add lactose-decomposing enzyme at a rate of 0.1g lactose-decomposing enzyme per 100g lactose. After reacting for 60 minutes, heat it to 85-90°C. Inactivate enzymes. Dilute the high-concentration milk that has completed the enzyme reaction to a solid content of about 20%. The lactose content of the obtained enzyme-hydrolyzed milk raw material is 0.9 (g / 100g); the content of galacto-oligosaccharide is 3.3 (g / 100g). Before the lactic acid fermentation process, add about 2% (w / w) fructooligosaccharides. Add B.bifidum (3×10 6 (CFU / g)) was fermented at 37°C for 10 hours, and the lactose content of the obtained fermented milk raw material was 0.6 (g / 100g); the content of galacto-oligosaccharides was 3.5 (g / 100g); 8 (CFU / g), the final pH value is 5.1.

example 2-1

[0051] Stir the milk powder evenly and dissolve it in water to form high-concentration milk (solid content is about 40%). Add lactose-decomposing enzyme at a rate of 0.1g lactose-decomposing enzyme per 100g lactose. After reacting for 60 minutes, heat it to 85-90°C. Inactivate enzymes. Dilute the high-concentration milk that has completed the enzyme reaction to a solid content of about 20.23%. The lactose content of the obtained enzyme-hydrolyzed milk raw material is 0.9 (g / 100g); the content of galacto-oligosaccharide is 3.2 (g / 100g). Add B.bifidum (2.8×10 6 (CFU / g)) was fermented at 37°C for 10 hours, and the lactose content of the obtained fermented milk raw material was 0.5 (g / 100g); the content of galacto-oligosaccharides was 2.5 (g / 100g); 8 (CFU / g), the final pH value is 5.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com