Steel wire bundling machine

A technology for bundling steel wires and steel wires, which is applied to parts of bundling machinery, bundling materials, paper/cardboard containers, etc., can solve problems such as not conforming to workers' usage habits, and achieve the effect of reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] This specific embodiment is only an explanation of the present invention, but not a limitation of the present invention. Any modifications made by those skilled in the art after reading the description of the present invention will be protected by the patent law as long as they are within the protection scope of the claims.

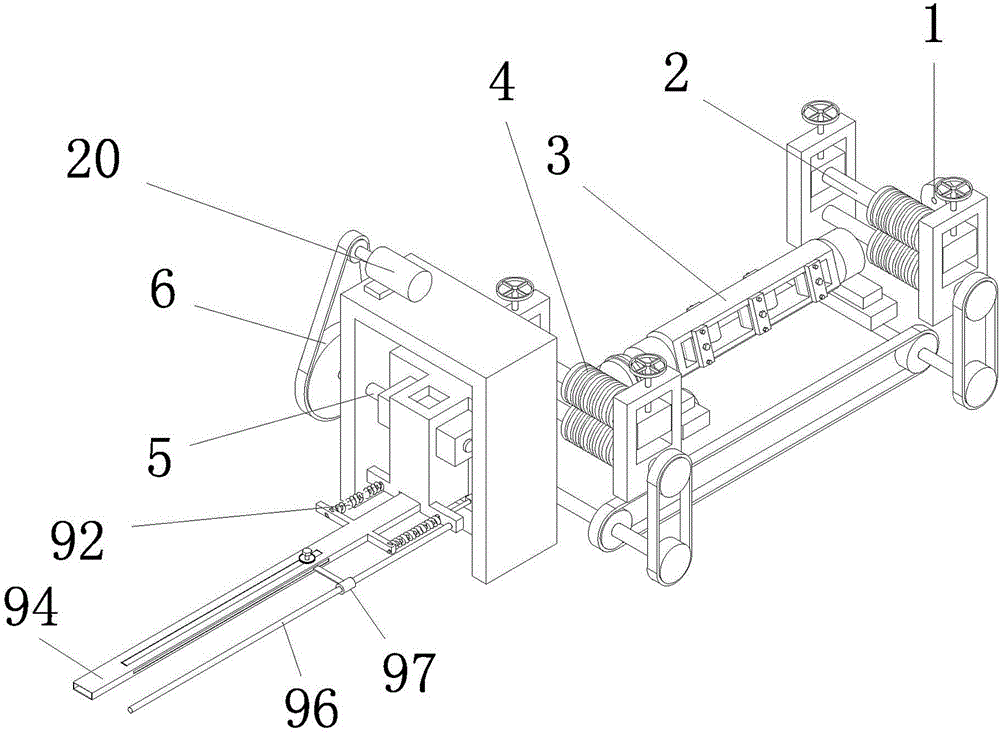

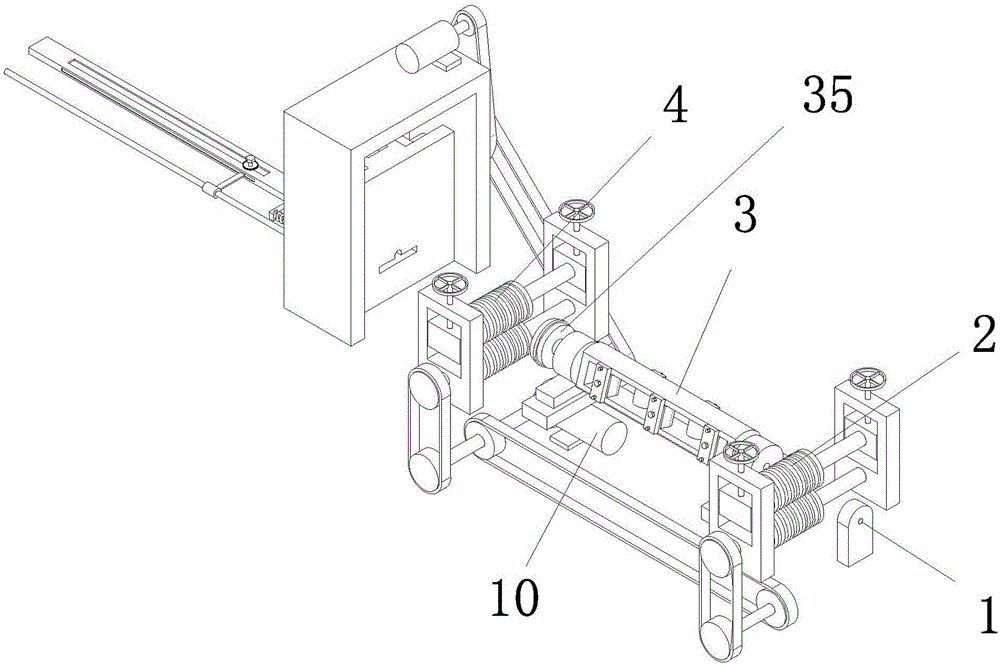

[0028] Such as Figure 1-5 As shown, the wire baler includes a straightening assembly and a cutting assembly.

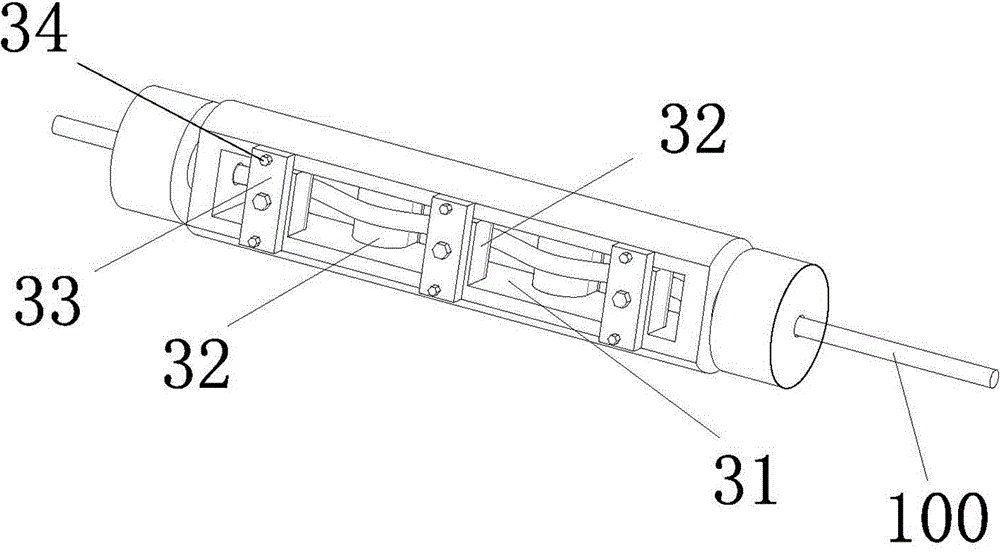

[0029] The straightening assembly includes a guide hole 1, a front pinch roller 2, a rotating bobbin 3 and a rear pinch roller 4, and the rotating bobbin 3 includes a bobbin body, a rotating shaft, several pads 32 and a pulley 35, and the bobbin body has For the front hole and the rear hole, the arrangement of the pads 32 makes the steel wire form a wavy line when passing through the rotating bobbin 3 . The bobbin body is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com