Air-bag type jack

A jack and airbag type technology, which is applied in the direction of lifting devices, etc., can solve the problems of shaking, unsmooth rise and fall, and inability to take out the airbag type jack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

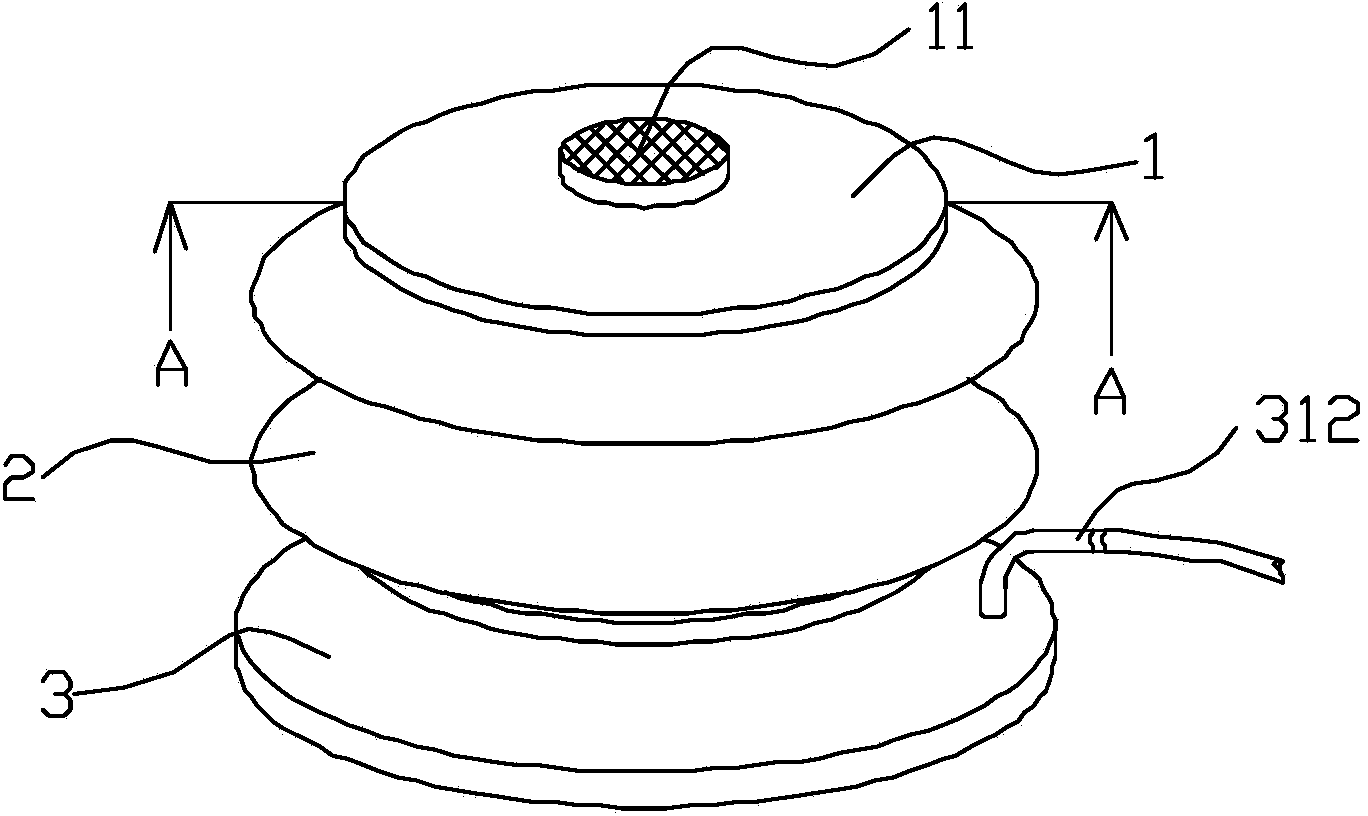

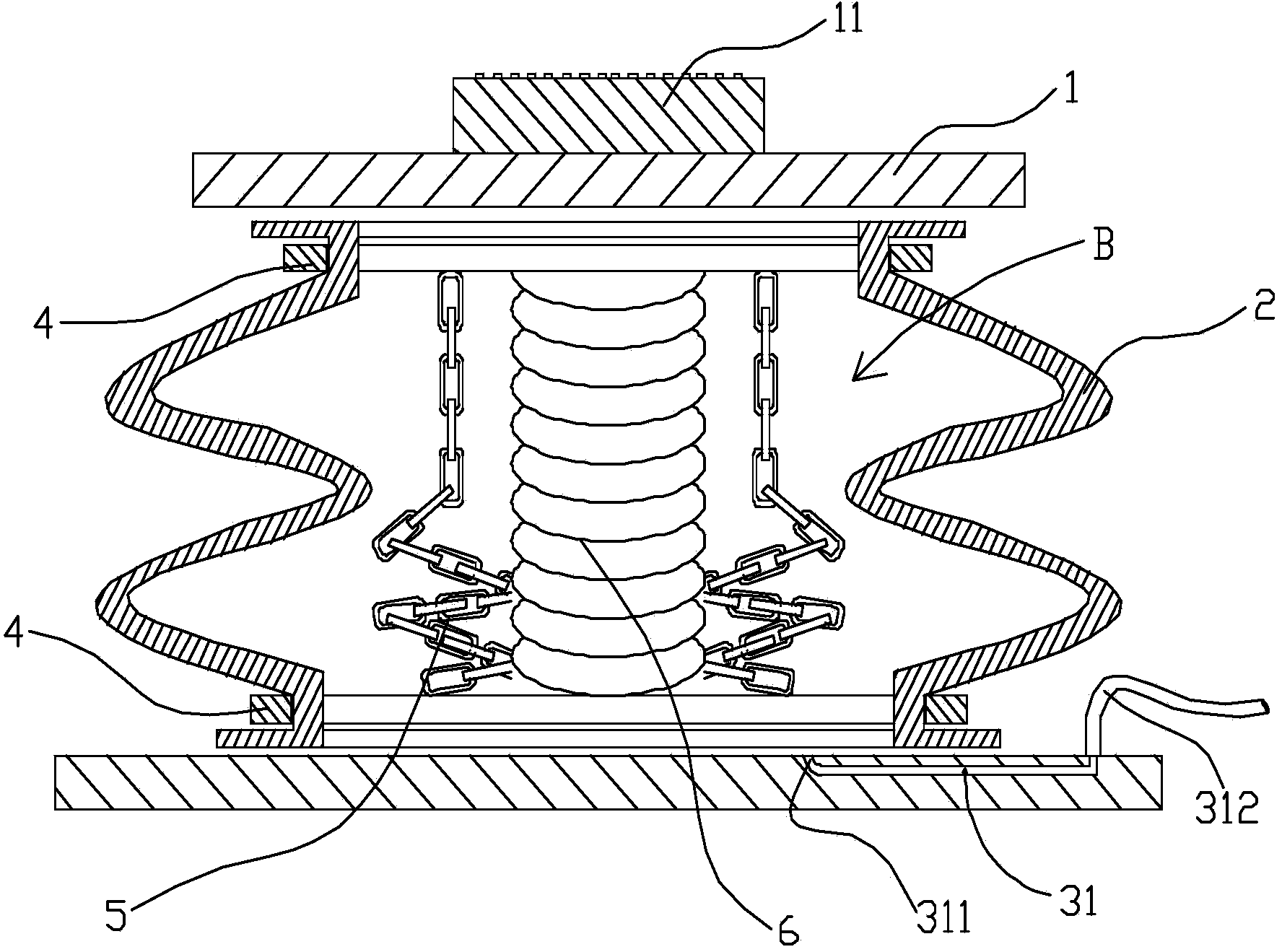

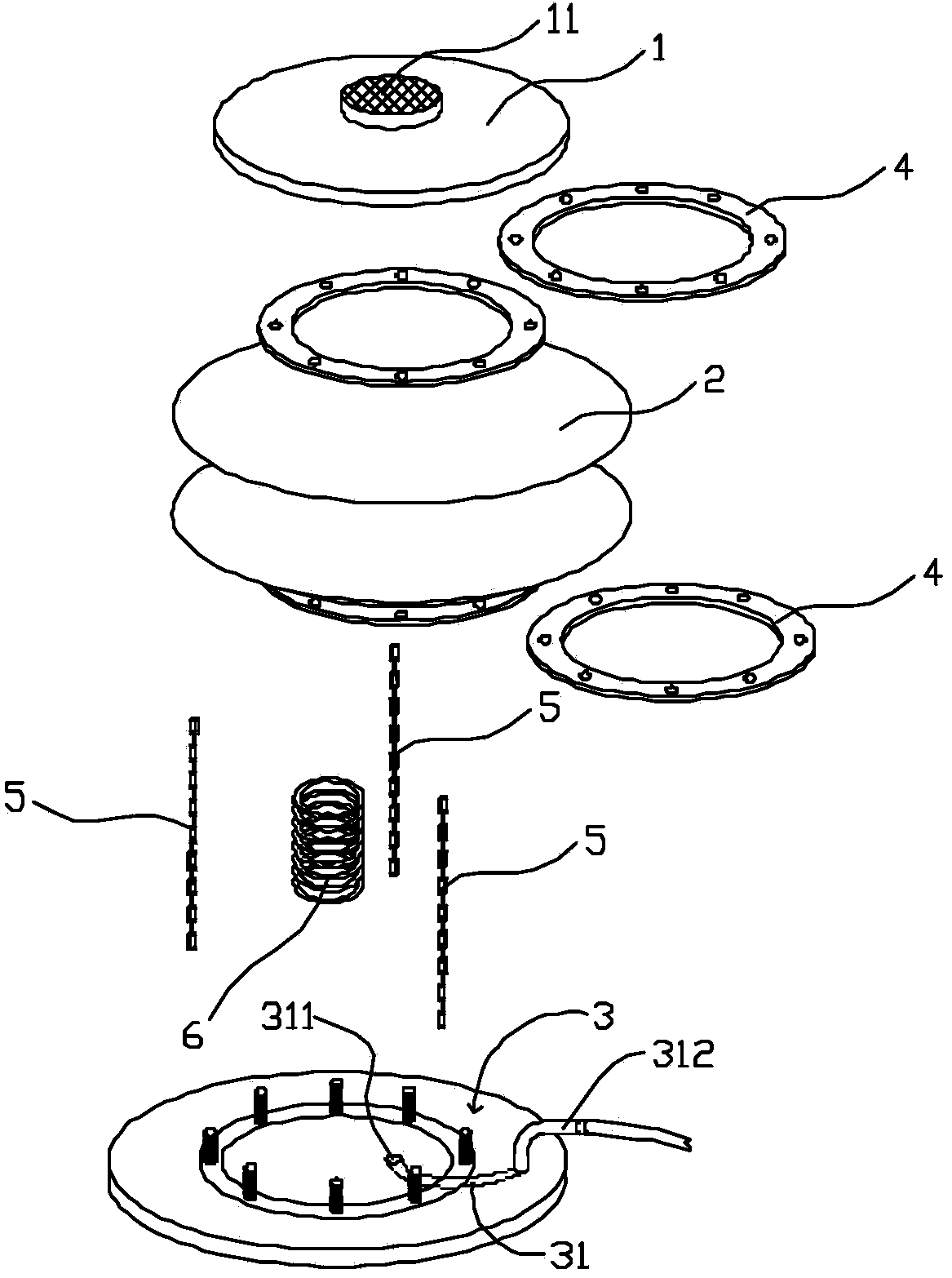

[0022] Figure 1 to Figure 3 A balloon jack according to one embodiment of the present invention is shown schematically. As shown in the figure, the device includes an upper top plate 1, a lower bottom plate 3, a rubber airbag 2 and a flange 4. The two ends of the rubber airbag 3 are sealedly connected to the upper top plate 1 and the lower bottom plate 3 through two flanges 4 respectively. The rubber airbag 2 A closed cavity B is thus formed inside.

[0023] A shock absorbing plate 11 is fixed on the upper top plate 1 .

[0024] The lower bottom plate 3 is connected to the high pressure air source through the air intake pipe 312 . An air inlet 31 is arranged in the lower bottom plate 3, and an air outlet 311 is arranged in the bag cavity B. The air intake pipe 312 is communicated with the air outlet 311 through the air intake passage 31 .

[0025] A balance limiting device is also provided inside the bladder cavity B.

[0026] In this embodiment, the balance limiting dev...

Embodiment 2

[0030] Figure 4 A balloon jack according to another embodiment of the present invention is schematically shown. The difference from Embodiment 1 is that a strap 7 is also included. As shown in the figure, the strap 7 bypasses the upper top plate 1 and is fixedly connected to the lower bottom plate 3 at both ends. In this embodiment, a hole and slot for the strap 7 to pass through is provided between the shock absorbing plate 11 and the upper top plate 1 . The straps 7 are not connected with the upper top plate 1 , and when the rubber airbag 2 rises, the straps 7 can slide on the upper top plate 1 , thereby achieving the purpose of keeping the upper top plate 1 in a balanced state. The strap 7 used in this embodiment is an industrial strength strap that can bear a force exceeding 2 tons.

[0031] In other embodiments, the balance limiting device may also be a strap 7 . When the air bag type jack works, the strap 7 slides on the upper top plate 1 , which can also ensure that...

Embodiment 3

[0034] Figure 5 A balloon jack according to yet another embodiment of the present invention is schematically shown. The difference from Embodiment 1 is that it also includes a control rod 8 and a heightening block 9 .

[0035] As shown in the figure, the height-increasing block 9 is placed on the upper top plate 1 to increase the lifting height of the air-bag type jack.

[0036] The control rod 8 is connected with the lower bottom plate 3 and includes a handrail 82 and a hollow straight rod 81 . The handrail 82 is arranged on one end of the straight rod 81 . The other end of the straight rod 81 is provided with a small wheel 83 . The air intake pipe 312 is penetrated inside the straight rod 81 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com