Ball bearing with self-measurement system

A ball bearing, self-measurement technology, applied in the direction of bearing components, shafts and bearings, bearing assembly, etc., can solve the problems of non-real-time, difficult to obtain the bearing running status in a timely and accurate manner, to improve reliability, determine reasonable configuration parameters, Structured novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

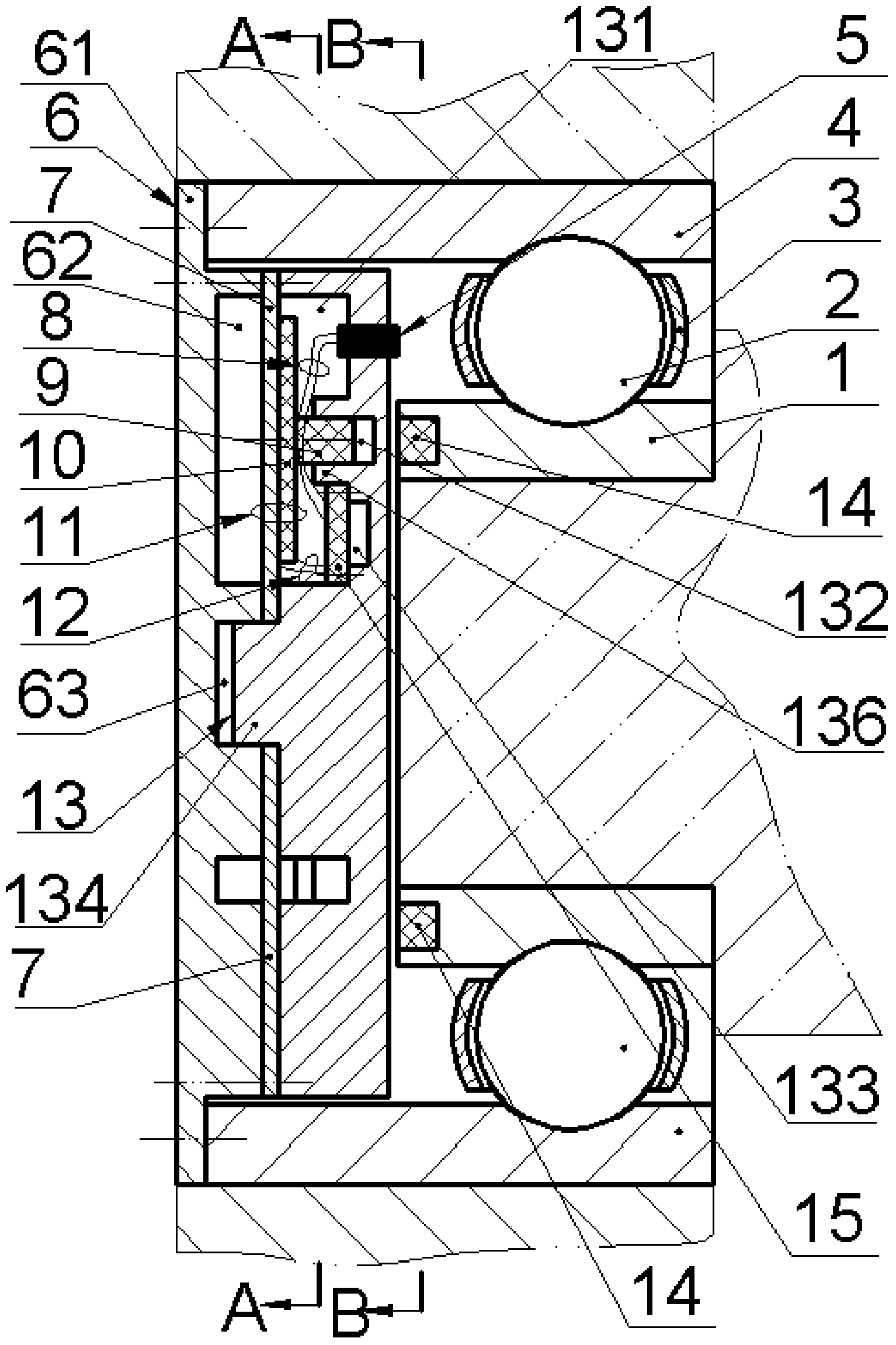

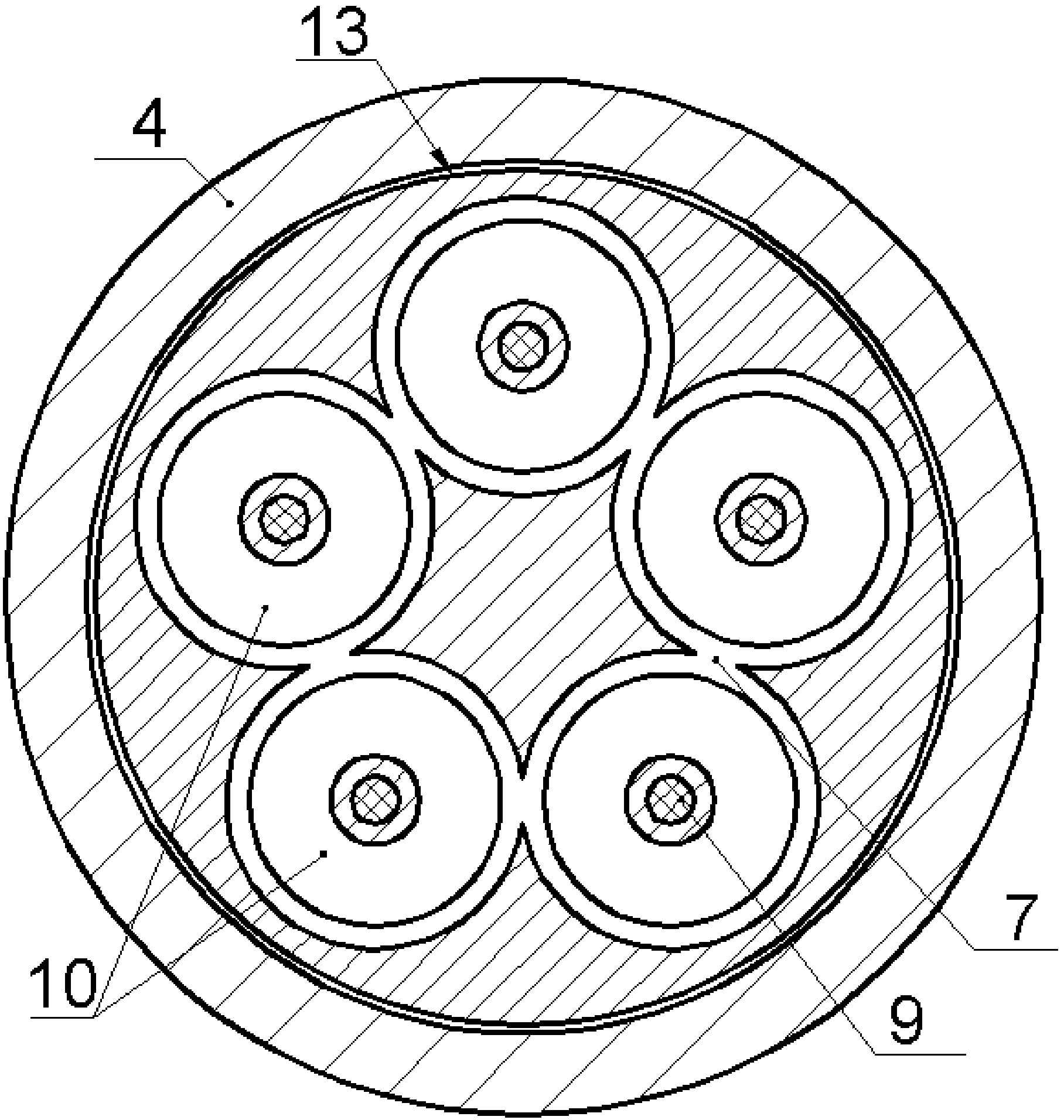

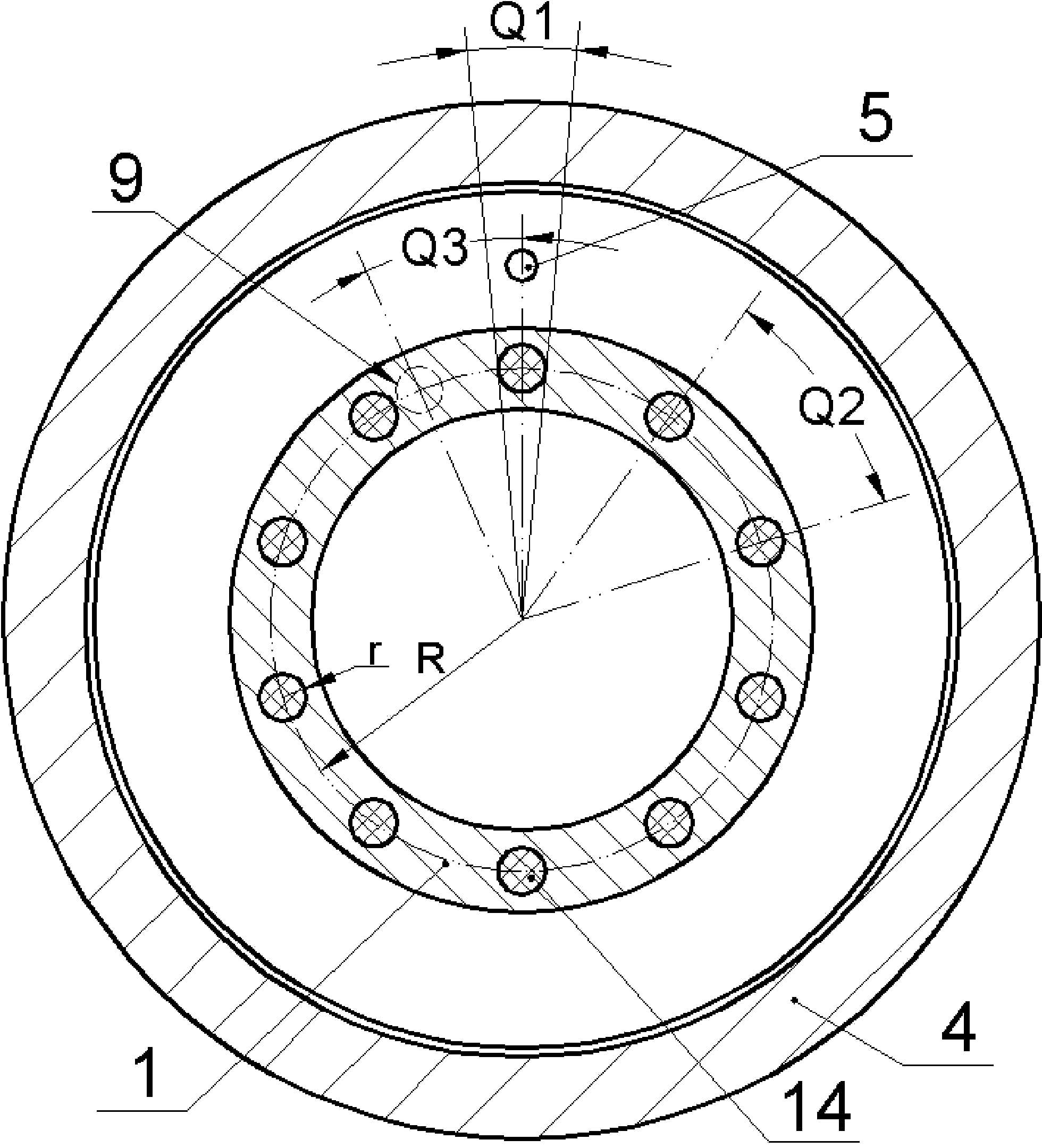

[0018] Such as Figure 1 ~ Figure 4 As shown, it includes inner ring 1, balls 2, cage 3, and outer ring 4. The width of the outer ring 4 is larger than that of the inner ring 1, and the inner ring 1 is installed in alignment with one side of the outer ring 4. On the non-aligned side, the end surface of the outer ring 4 is fixed with a connecting flange 61 of the cover plate 6 by screws, and the side of the cover plate 6 close to the inner ring 1 is provided with a set of concave cavity 1 62 and a positioning hole 63, and A guard plate 13 is installed by screws, and the guard plate 13 is provided with a cavity two 131 opposite to the cavity one 62 on the cover plate 6 and a positioning shaft opposite to the positioning hole 63 on the cover plate 6 134, at least one through hole 135 for installing the sensor 5, a ring groove 133 for installing the circuit board 15, a boss 136 and a guide hole 132 are provided at the bottom of the second concave cavity 131, and the cover plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com