Automobile reverse-transmission switchover device

A technology of reverse transmission and switching device, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of collision and impact, affecting the stability of transmission system and vehicle safety, and achieve long service life , Reasonable design, small shift impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

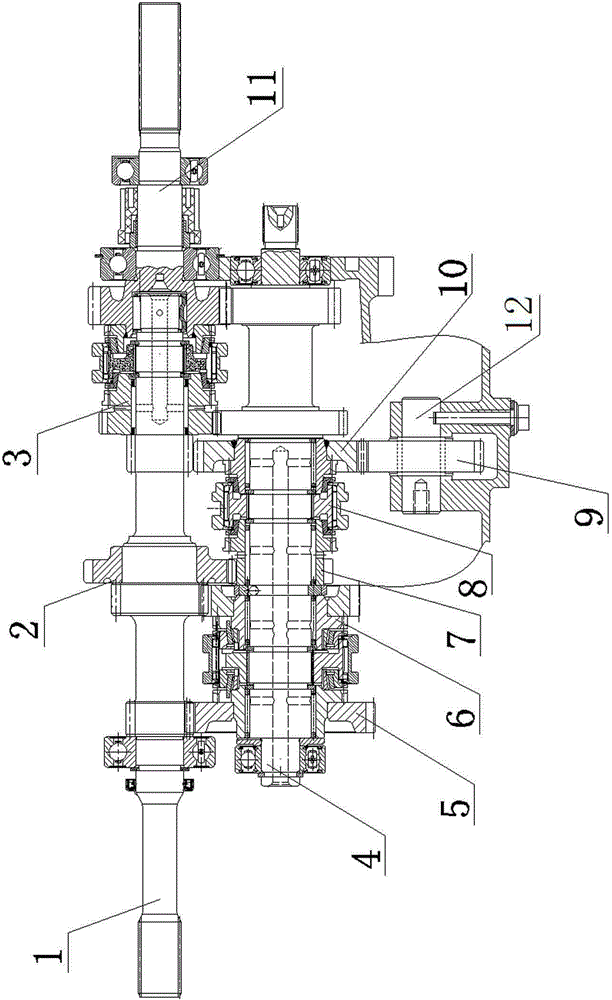

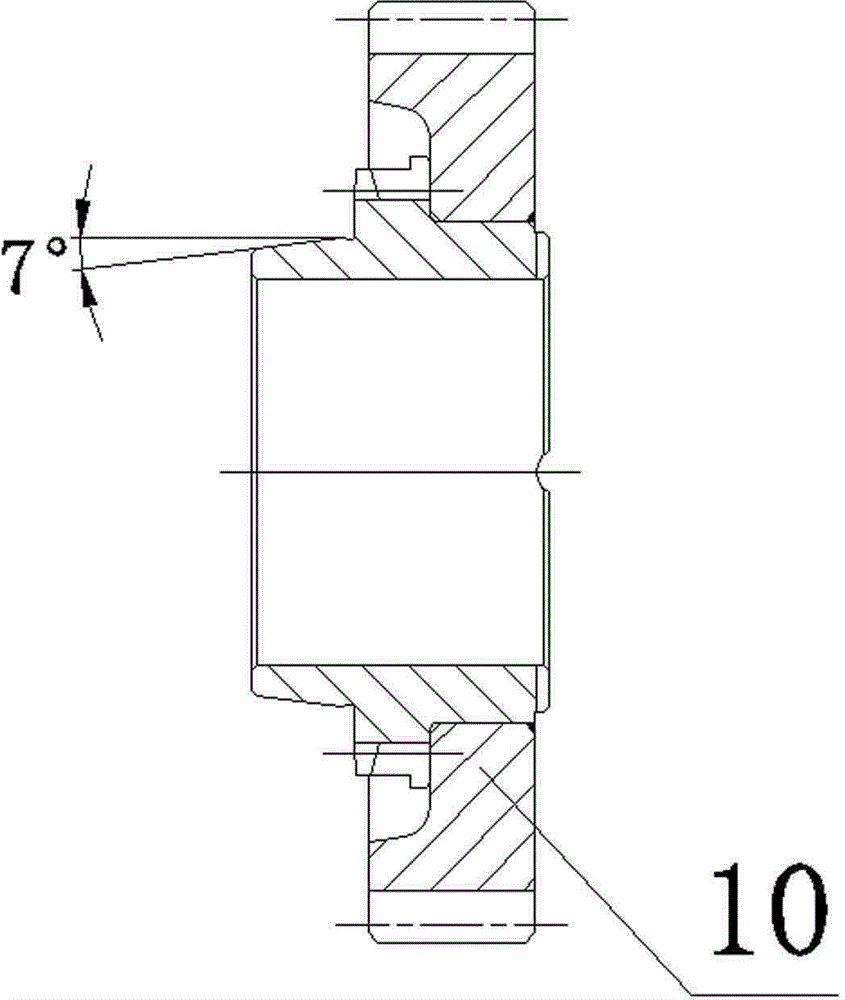

[0035] The automobile reverse transmission switching device comprises an input shaft 1, an intermediate shaft 4, an output shaft 11 and an idler shaft 12, the input shaft 1 and the output shaft 11 are on the same axis, and the input shaft No. 3 gear 2 and the input shaft 1 are installed on the input shaft 1. Shaft No. 5 gear 3; counter shaft 4 is equipped with counter shaft No. 1 gear 5, counter shaft No. 2 gear 6, counter shaft No. 5 gear 7, reverse transmission switching device 8 and reverse gear 10, and counter gear 10 The angle between the conical surface contacted by the reverse transmission switching device 8 and the horizontal direction is 7°; the idler shaft 12 is equipped with a reverse idler 9 .

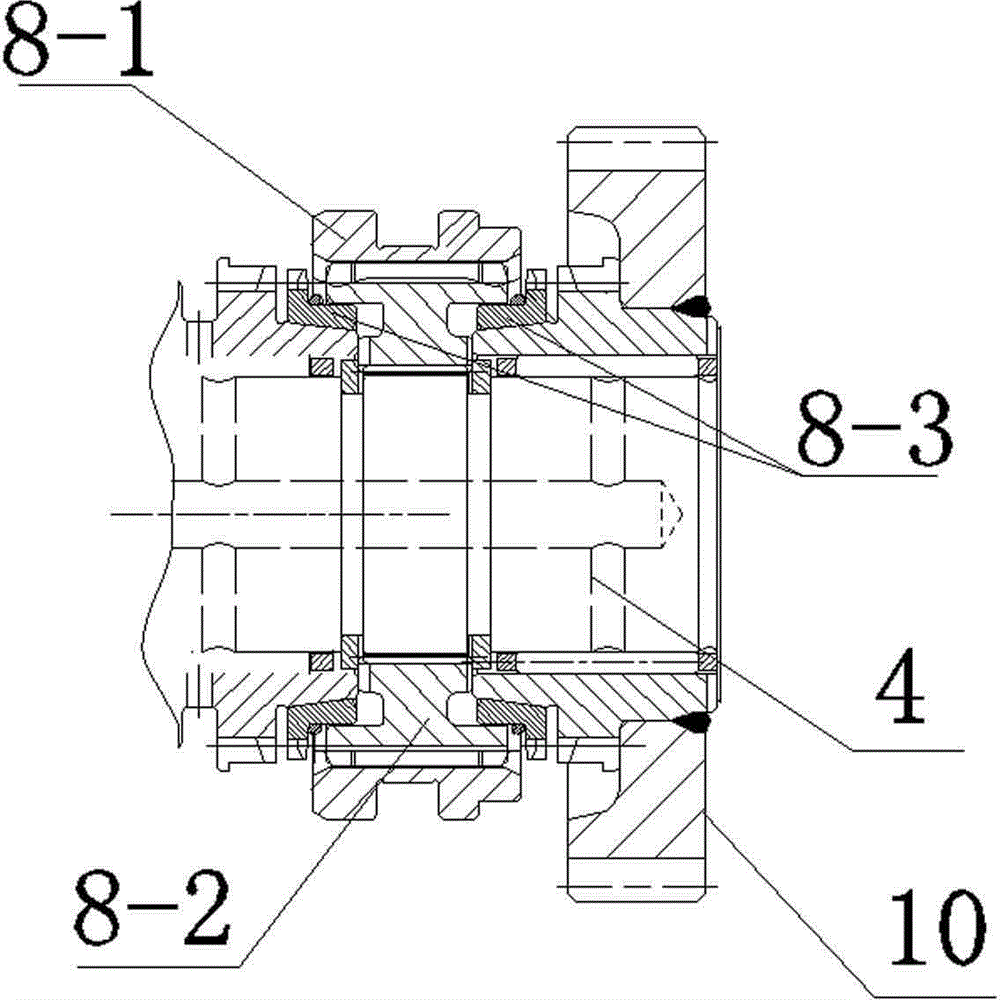

[0036] The reverse transmission switching device 8 is composed of a gear sleeve 8-1, a gear hub 8-2 and a gear ring 8-3, the gear hub 8-2 is installed in the gear sleeve 8-1, and the two sides of the gear hub 8-2 are respectively installed There is a gear ring 8-3. The...

Embodiment 2

[0038] The automobile reverse transmission switching device comprises an input shaft 1, an intermediate shaft 4, an output shaft 11 and an idler shaft 12, the input shaft 1 and the output shaft 11 are on the same axis, and the input shaft No. 3 gear 2 and the input shaft 1 are installed on the input shaft 1. Shaft No. 5 gear 3; counter shaft 4 is equipped with counter shaft No. 1 gear 5, counter shaft No. 2 gear 6, counter shaft No. 5 gear 7, reverse transmission switching device 8 and reverse gear 10, and counter gear 10 The angle between the conical surface contacted by the reverse transmission switching device 8 and the horizontal direction is 7°; the idler shaft 12 is equipped with a reverse idler 9 .

[0039] The reverse transmission switching device 8 is composed of a gear sleeve 8-1, a gear hub 8-2 and a gear ring 8-3, the gear hub 8-2 is installed in the gear sleeve 8-1, and the two sides of the gear hub 8-2 are respectively installed There is a gear ring 8-3. The...

Embodiment 3

[0041] The automobile reverse transmission switching device includes an input shaft 1, an intermediate shaft 4, an output shaft 11 and an idler shaft 12, the input shaft 1 and the output shaft 11 are on the same axis, and the input shaft No. 3 gear 2 and the input shaft 1 are installed on the input shaft 1. Shaft No. 5 gear 3; counter shaft 4 is equipped with counter shaft No. 1 gear 5, counter shaft No. 2 gear 6, counter shaft No. 5 gear 7, reverse transmission switching device 8 and reverse gear 10, and counter gear 10 The angle between the conical surface contacted by the reverse transmission switching device 8 and the horizontal direction is 7°; the idler shaft 12 is equipped with a reverse idler 9 .

[0042] The reverse transmission switching device 8 is composed of a gear sleeve 8-1, a gear hub 8-2 and a gear ring 8-3, the gear hub 8-2 is installed in the gear sleeve 8-1, and the two sides of the gear hub 8-2 are respectively installed There is a gear ring 8-3. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com