Double-rotation spraying and flushing device used for assisting in lifting marine drilling platform pile shoe

An offshore drilling platform, dual-rotation technology, which is applied in the direction of jetting device, spraying device with movable outlet, valve device, etc. Small and other problems, to achieve the effect of shortening the transfer cycle of the work area, speeding up the lifting, and improving the spray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

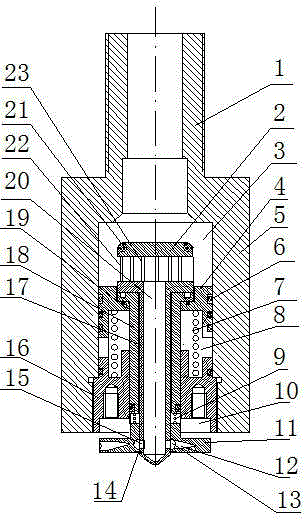

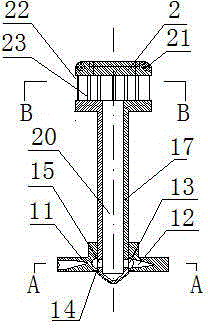

[0019] The spray flushing device working process of the present invention is as follows:

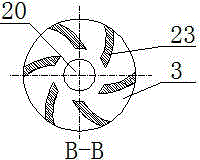

[0020] High-pressure water enters from the interface pipe, pushes the valve core to move down, and the valve core moves down in conjunction with the annular piston. During the process of the valve core moving down, the valve stem moves down to push the rotary nozzle plate away from the concave hole at the lower end of the end cover, exposing the turbojet hole , high-pressure water enters the water inlet hole of the valve core from the valve cavity and impacts the turbine blade in the water inlet hole to push the valve core to rotate, high-pressure water enters the water outlet channel in the center of the valve stem from the water inlet hole, and then sprays out from the water outlet hole at the lower end into the rotary valve. The annular groove of the spray plate, the annular groove distributes the water to the vortex spray hole on the vortex spray plate, and the vortex spray hole spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com