Waterproof connector and manufacturing method thereof

A technology of waterproof connector and manufacturing method, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of poor waterproofness, difficult terminal modules, etc., and achieve the effect of good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

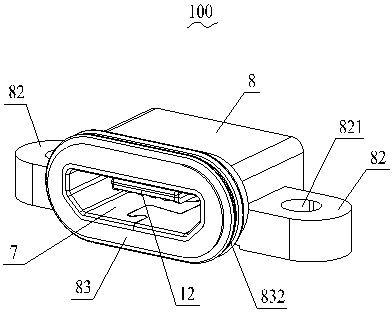

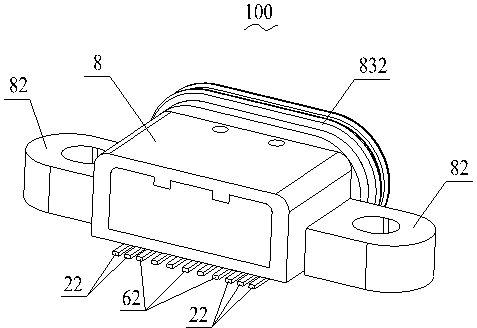

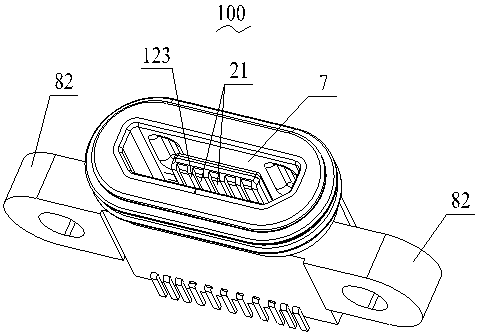

[0030] Please refer to Figure 1 to Figure 6 As shown, the illustrated embodiment of the present invention discloses a waterproof connector 100, which includes a first terminal module 10, a second terminal module 20 assembled with the first terminal module 10, and a covering The shielding housing 7 of the first and second terminal modules 10 and 20, and the injection molding on the first and second terminal modules 10 and 20 and the shielding housing 7 after the assembly of the first and second terminal modules 10 and 20 are completed 10, 20 and the injection molded parts 8 on the outside of the housing 7 . . In the illustrated embodiment of the present invention, the waterproof connector 100 is a Micro Universal Serial Bus (Micro USB) connector.

[0031] The first terminal module 10 includes a first insulating body 1, a number of first terminals 2 insert molded in the first insulating body 1, and a plurality of first terminals 2 insert molded in the first insulating body 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com