Three-axis voice coil motor for controlling camera movement

A voice coil motor and motion technology, applied in installation, optics, instruments, etc., can solve the problems of inability to adapt to the trend of ultra-light and ultra-thin smartphones, inability to install, complex structure, etc. Easy to install and assemble, simple and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

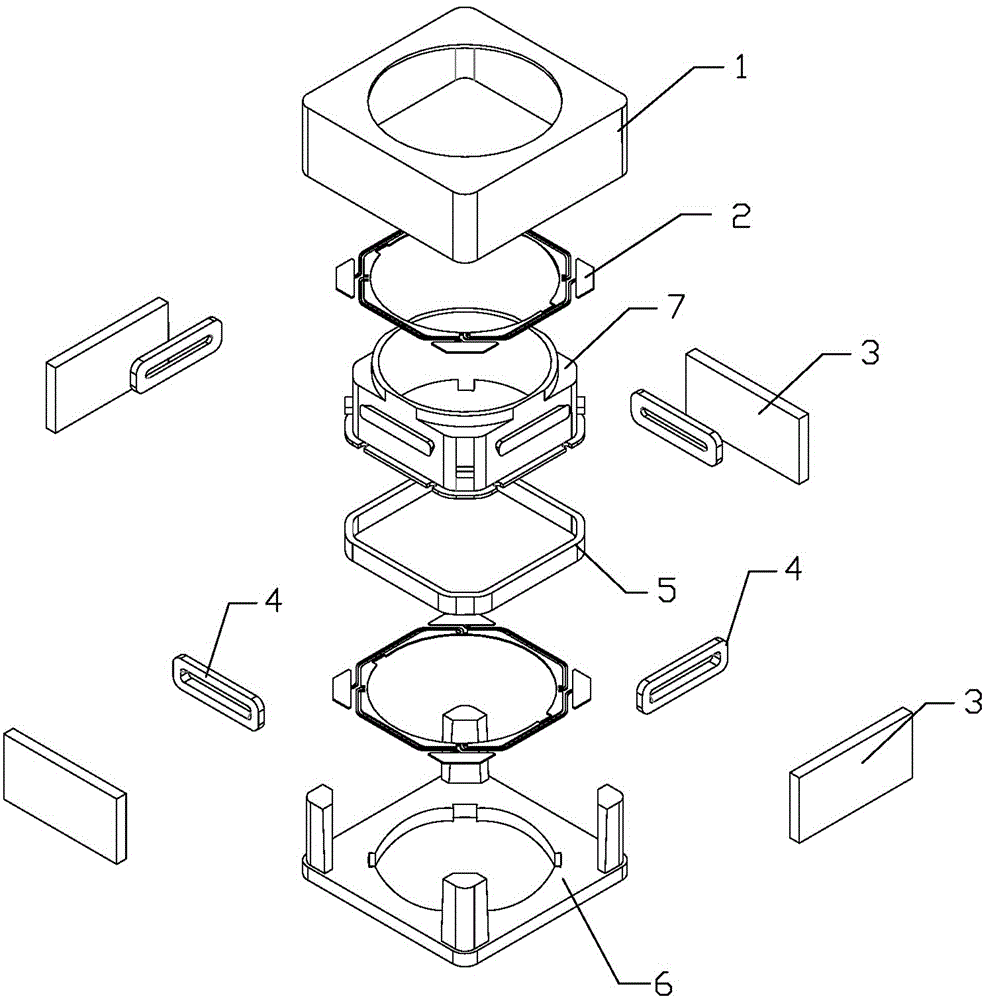

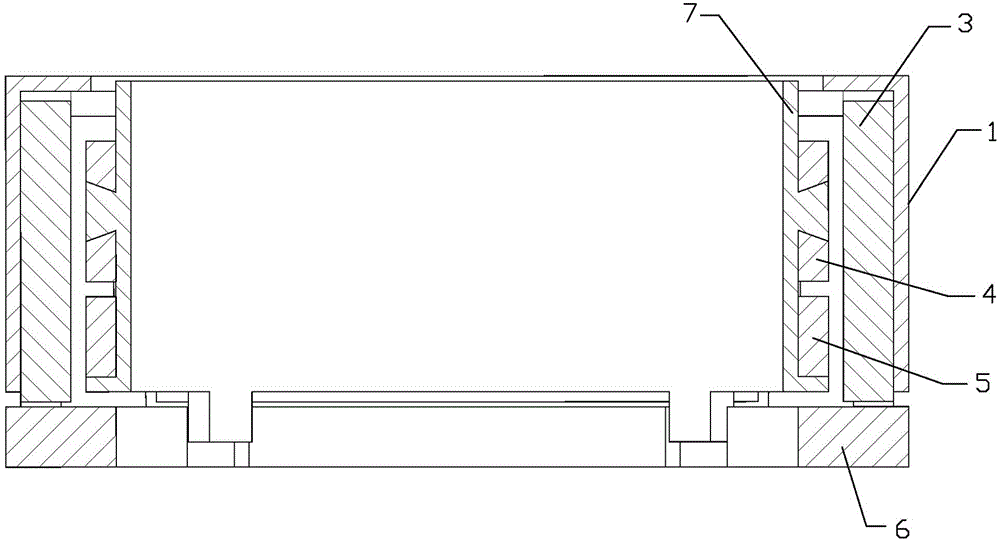

[0014] The 3-axis voice coil motor for controlling lens movement provided by the present invention mainly includes a housing, a lens mount 7 , a translation coil 4 , a focus coil 5 , a magnet 3 and a spring piece 2 .

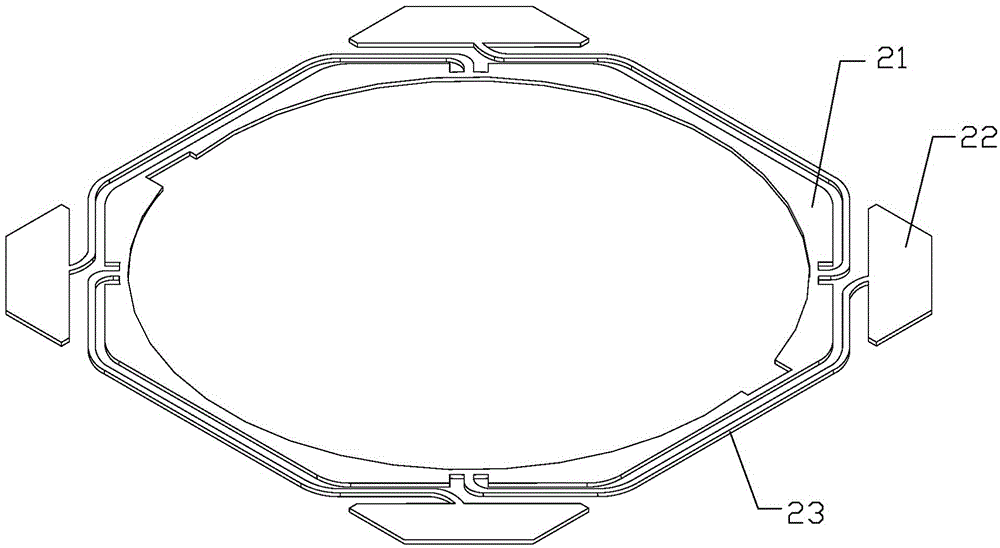

[0015] The shell is composed of a bottom cover 6 and a yoke 1. The yoke 1 is made of metal, which can effectively isolate the internal and external magnetic fields of the shell. The housing is provided with a lens holder 7 matching its shape. The lens holder 7 is elastically connected to the housing through a spring piece 2. For example, the end of the lens holder can be connected to the bottom cover or the top of the yoke through a spring piece 2. 2 leaf springs are connected to both of them. The translation coils 4 are arranged symmetrically on the periphery of the lens holder 7, and the number of the translation coils 4 can be set to 2, or more than 2, such as 4, etc. according to the situation. A focusing coil 5 is sheathed on the periphery of one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com