Splicing and compounding formation device of cracked stone

A molding device, stone technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of lack of combination, large impact force, etc., and achieve the effect of solving fragile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

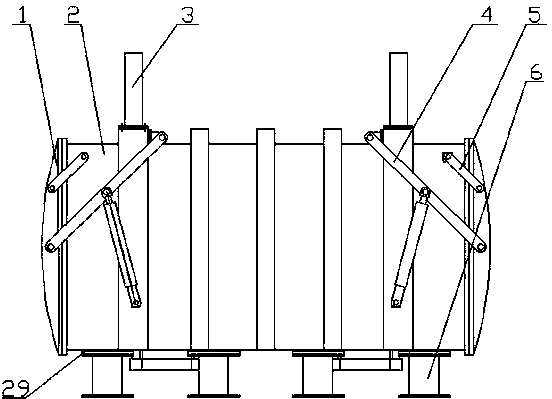

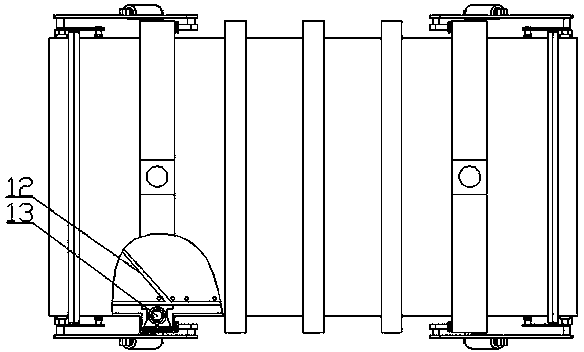

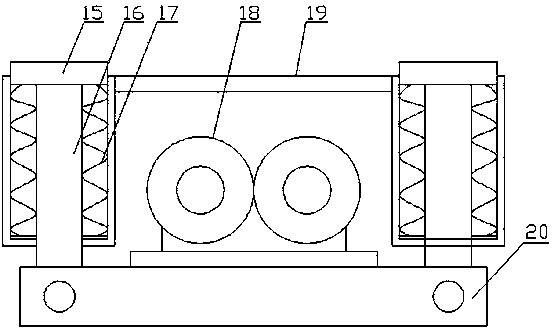

[0026] like figure 1 , 2 , shown in 3, the present invention comprises that two ends are provided with the vacuum box 2 of sealed door oil cylinder 4 and connecting rod 15 transmission sealed door 1, the trolley that runs along guide rail, the pressing plate 12 that slides along transmission rod 13 with oil cylinder 3 linkages, The template 8 placed between the pressure plate 12 and the boss of the vacuum box 2 and supported by interlayer springs 9, and the vibration assembly 11 hoisted from the lower part, the pressure plate 12 and the two oil cylinders 3 are connected by rotating shafts, with a stroke of 400-800mm Vertical movement, the two ends of its length direction are fixed with guide sleeves sliding along the transmission rod 13; the upper flange and the lower flange are passed between the pressure plate 12 and the oil cylinder 3, elastically supported by buffer springs, and fixed The movable chuck mounted on the pressure plate 12 lifts the piston-like lower piston ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com