elevator

An elevator and elevator car technology, applied in the elevator field, can solve problems such as counterweight collision, and achieve the effects of reducing shaking, realizing miniaturization, and convenient installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

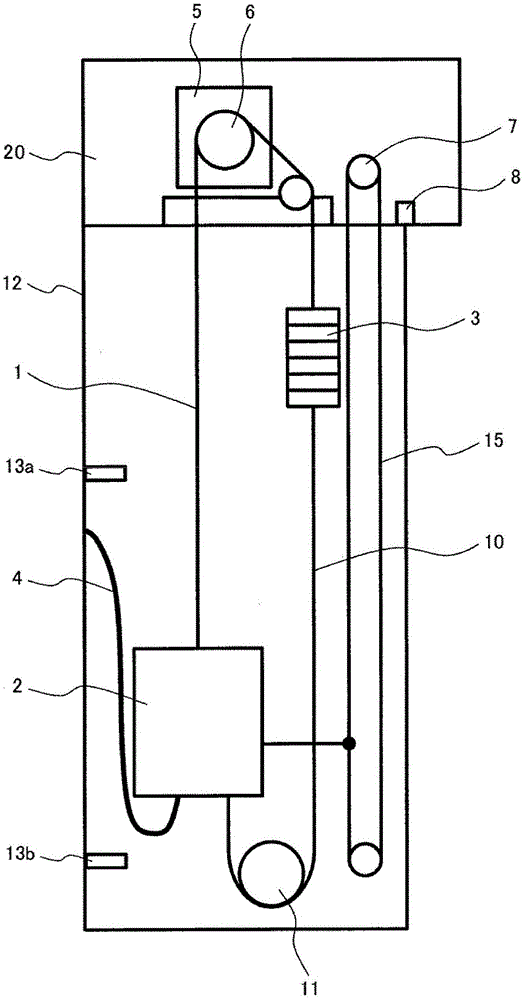

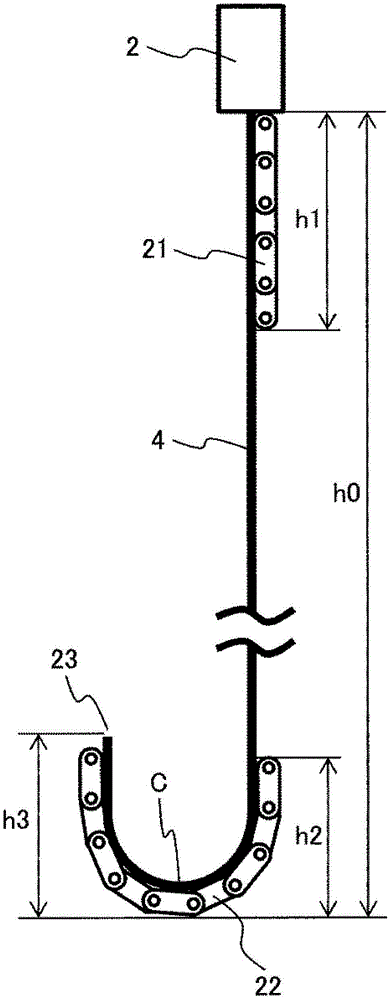

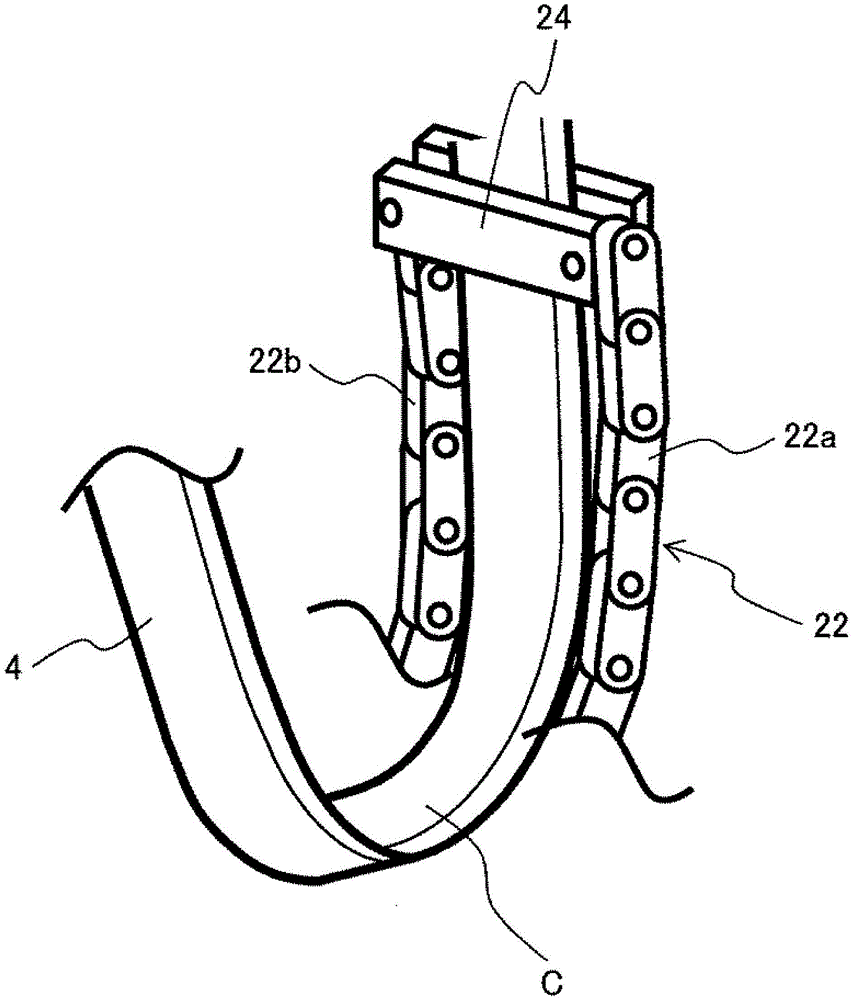

[0042] Below, refer to figure 2 and image 3 A first embodiment of the present invention will be described. In this embodiment, a vibration damping mechanism that shortens the natural period of the power supply cable 4 to be shorter than the natural period of a high-rise building is shown. Specifically, it shows that in the state where the elevator car 2 is located on the floor of the high-rise area, the part of the reinforced power supply cable 4 that is close to the wall surface of the hoistway 12 to the bent back portion of the power supply cable 4 is shown. The rigidity between, thereby effectively shortening the natural period of the structure.

[0043] exist figure 2 Shown in the case that elevator car 2 stops at the high-rise area floor (such as the highest floor) of high-rise building or the lower floor of several floors lower than this floor. In the following description, it is assumed that the elevator car 2 stops at the uppermost floor.

[0044] In general, w...

no. 2 example

[0078] Below, refer to Figure 4 and Figure 5 A second embodiment of the present invention will be described. In this embodiment, a vibration damping mechanism in which the natural period of the power supply cable 4 is extended to be longer than the natural period of a high-rise building is shown. Specifically, a structure is proposed in which, when the elevator car 2 is located on the floor of a high-rise area, a weight is fixed near the bent and bent portion of the power supply cable 4, thereby effectively extending the inherent length. cycle.

[0079] exist Figure 4 Shown in the case that elevator car 2 stops at the high-rise area floor (such as the highest floor) of high-rise building or the lower floor of several floors lower than this floor. In the following description, as in the first embodiment, it is assumed that the elevator car 2 stops at the uppermost floor.

[0080] The weight 25 for prolonging the natural period of the power supply cable 4 cannot be casua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com