Functional separation type combined support system and its construction method

A function separation and bearing technology, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of insufficient attenuation performance and reset ability of bearings, lack of horizontal shear deformation function of bearings, and high processing accuracy requirements. Achieve the effect of clear mechanical behavior, prolong the inherent cycle, and reduce the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The embodiments will be described in detail below in conjunction with the accompanying drawings.

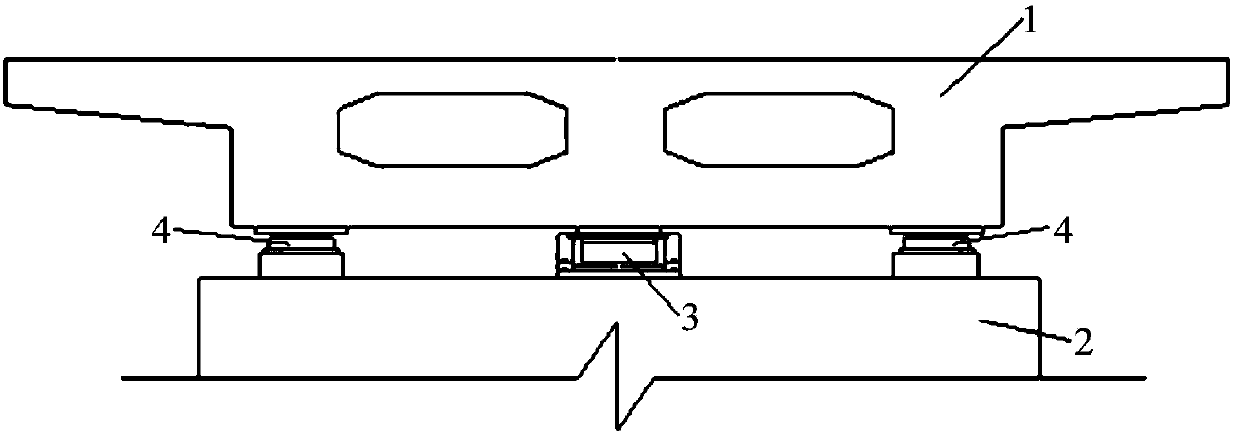

[0053] See attached figure 1 , a group of functionally separated combined bearing systems, fixed between the beam body 1 and the bridge pier 2 through anchor bolts, and the top cross bridge of the bridge pier 2 is provided with a self-resetting lead rubber bearing 3 in the middle to provide horizontal shear deformation Function: a basin-type rubber support 4 is provided on both sides of the cross bridge on the top of the pier 2, providing the function of rotation deformation and vertical support.

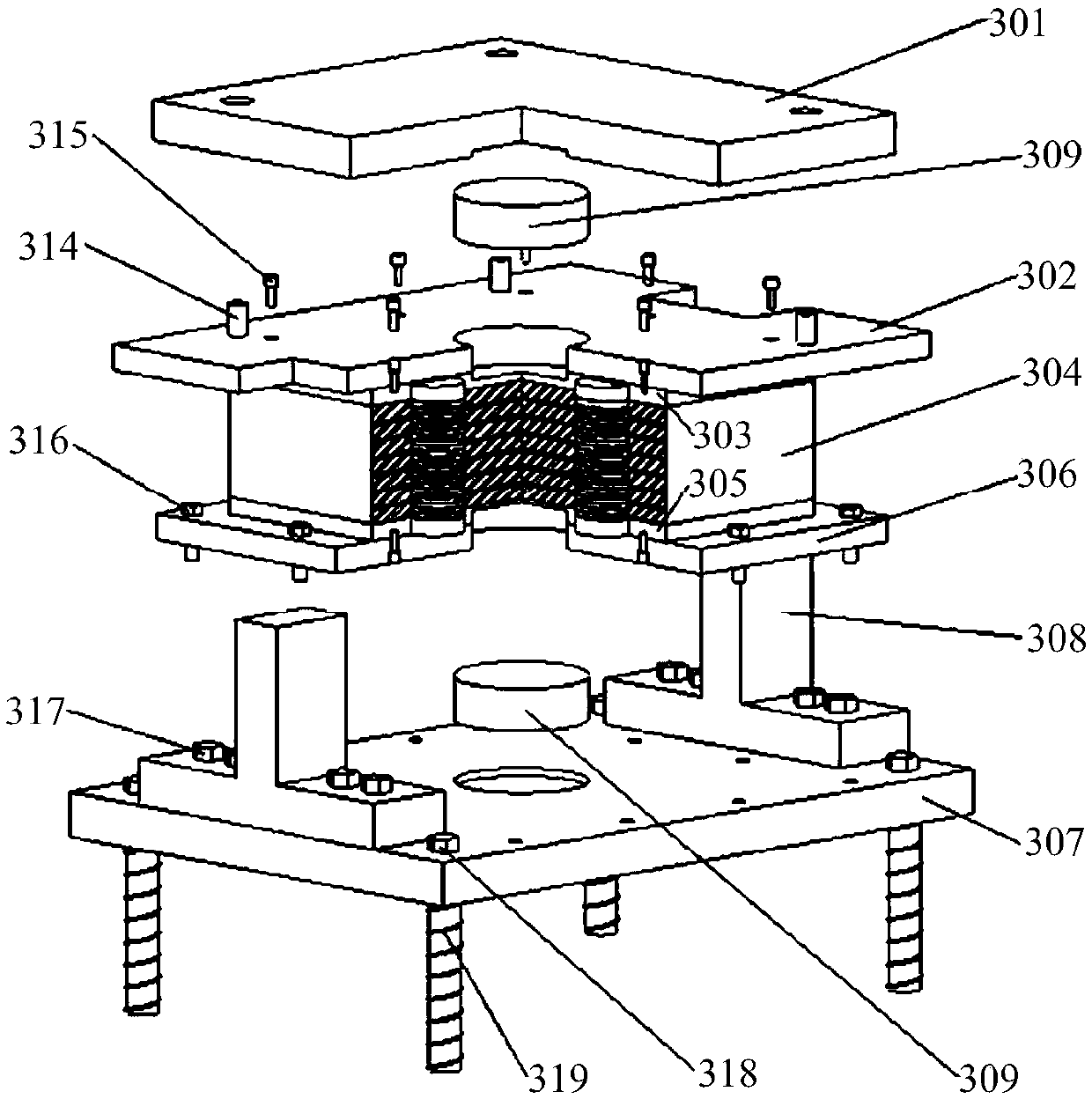

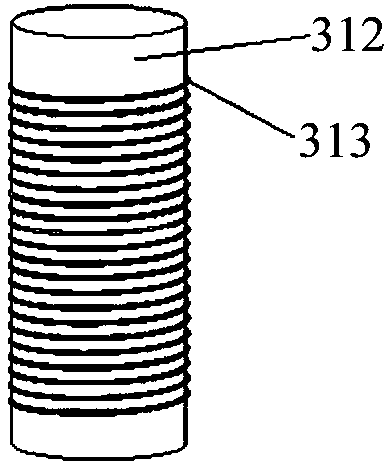

[0054] See attached figure 2 , the self-resetting lead rubber support 3 includes a steel plate A301 on the support, a deformation restraint plate 302, a first connecting steel plate 303, a rubber plate A304, a second connecting steel plate 305, a bottom plate 306 and a steel plate 307 under the support, the The steel plate A301 on the support is fixed on the bottom of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com