One-time molding crimping device for composite insulators

A technology of composite insulators and crimping devices, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of high labor intensity, low work efficiency, and inconvenient operation, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

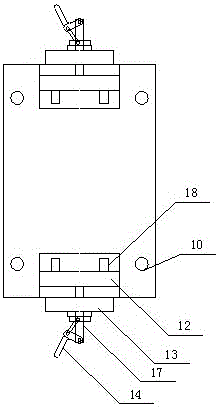

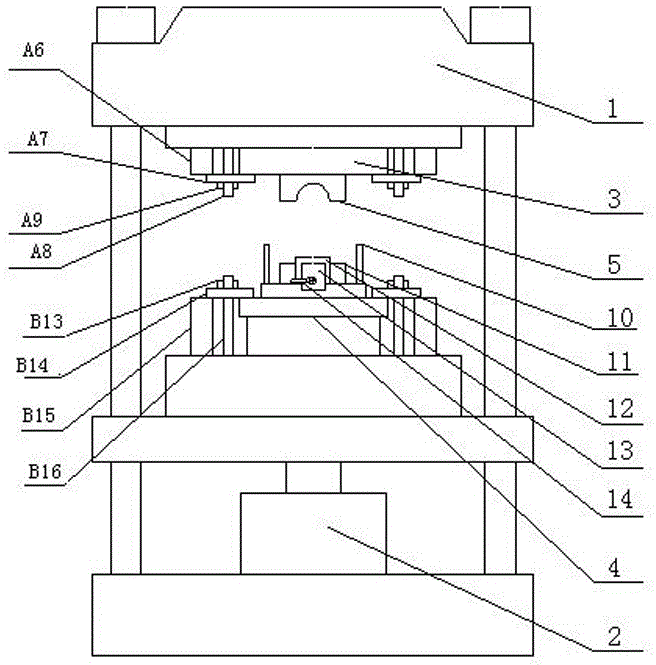

[0018] like figure 1 It can be seen from the schematic diagram that the composite insulator forming crimping device of the present invention includes a frame 1 , a working platform and a driving cylinder 2 .

[0019] Work platform is installed in the inside of frame, and work platform comprises upper fixed platform 3 and lower movable platform 4, and lower movable platform 4 can be driven away from or near upper fixed platform 3 by drive cylinder 2 installed in frame 1.

[0020] Mandrel limit blocks 5 are distributed on the lower surface of the upper fixed platform 3, guide holes are arranged at four corners of the lower surface of the upper fixed platform 3, and the upper fixed platform 3 is fixed on the machine by the platform holders A around it. inside the shelf.

[0021] The platform fixing seat A includes a threaded connecting rod A8, a pressure plate A7, a fixing seat A6 and a lock nut A9, the fixing seat A6 is installed on the frame 1, the threaded connecting rod A8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com