Co-doped polypyrrole material and its preparation method and application

A polypyrrole, co-doping technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of polypyrrole and high impedance that cannot be overcome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

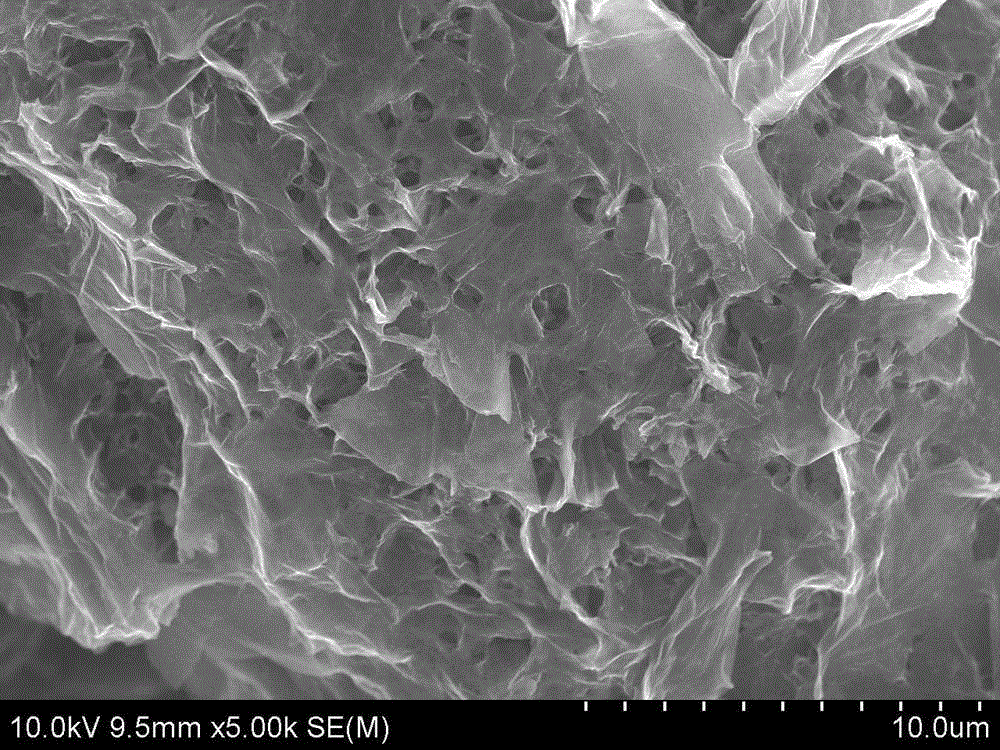

[0021] Prepare an aqueous solution containing 0.1M pyrrole monomer, 0.0005MAQS sulfate, and 1.0mg / ml graphene oxide (GO), and pass N 2 After 30 min, the three-electrode system was used for constant current electrodeposition, and the applied current was 0.5mAcm -2 , the electric quantity of electrodeposition is 1.2 coulombs; the obtained PPy / AQS / GO composite material is washed and placed in a three-electrode system for electrochemical reduction, the applied voltage is 1.1V, and the electrolyte is PBS buffer solution. After the reaction The PPy / AQS / r-GO electrode material can be obtained by repeated washing with water.

Embodiment 2

[0023] Prepare an aqueous solution containing 0.2M pyrrole monomer, 0.0005MAQS sulfate, and 1.0mg / ml graphene oxide (GO), and pass N 2 After 30 min, the three-electrode system was used for constant current electrodeposition, and the applied current was 2mAcm -2 , the electric quantity of electrodeposition is 2.0 coulombs; the obtained PPy / AQS / GO composite material is washed and placed in a three-electrode system for electrochemical reduction, the applied voltage is 1.2V, and the electrolyte is PBS buffer solution. After the reaction The PPy / AQS / r-GO electrode material can be obtained by repeated washing with water.

Embodiment 3

[0025] Prepare an aqueous solution containing 0.05M pyrrole monomer, 0.1MAQS sulfate, and 1mg / ml graphene oxide (GO), and pass N 2 After 30 min, the three-electrode system was used for constant current electrodeposition, and the applied current was 1mAcm -2 , the electric quantity of electrodeposition is 1.6 coulombs; the obtained PPy / AQS / GO composite material is washed and placed in a three-electrode system for electrochemical reduction, the applied voltage is 1.0V, and the electrolyte is PBS buffer solution. After the reaction The PPy / AQS / r-GO electrode material can be obtained by repeated washing with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com