Catalyst for fuel cell, preparation method of catalyst and fuel cell

A technology of fuel cells and catalysts, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor catalytic activity and stability of Pt catalysts, and cannot meet the needs of practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

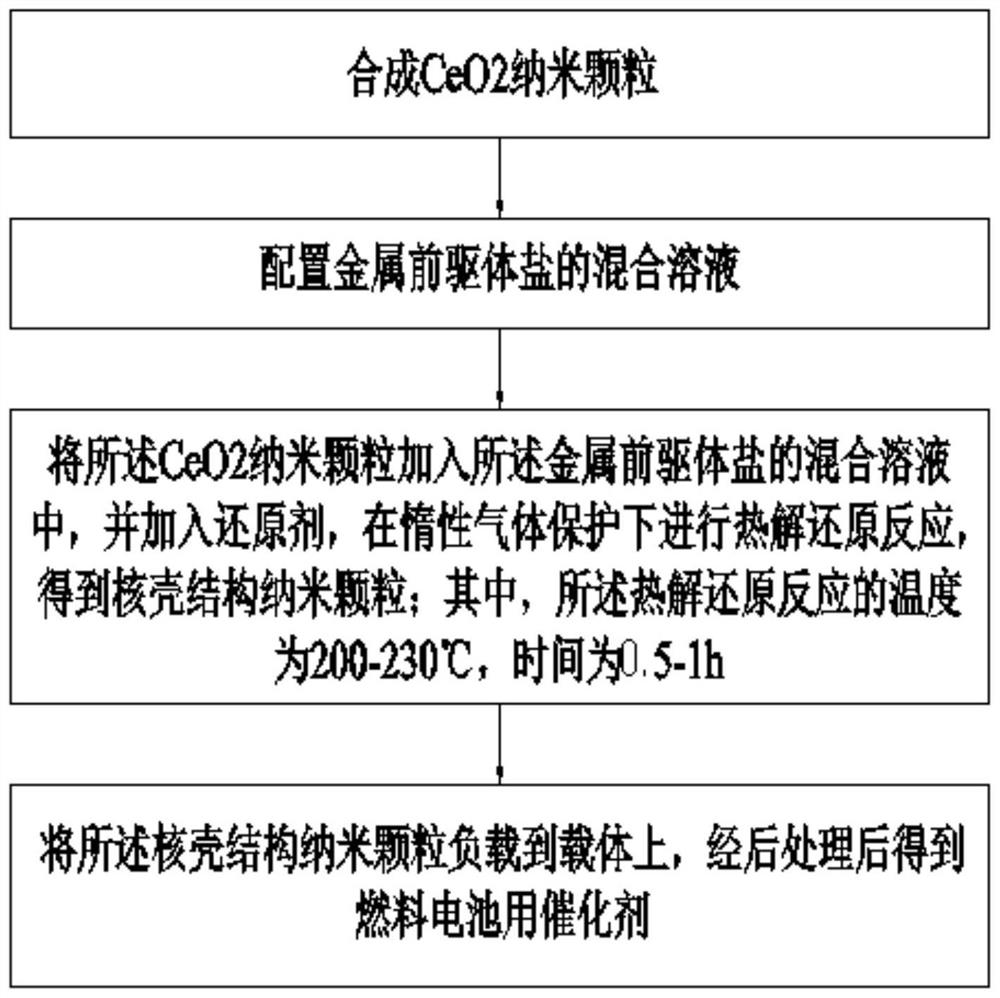

[0037] combine figure 1 As shown, the preparation method of the catalyst for a fuel cell according to the embodiment of the present invention includes the following steps:

[0038] Synthetic CeO 2 Nanoparticles;

[0039] Configure the mixed solution of metal precursor salt;

[0040] the CeO 2 Nanoparticles are added to the mixed solution of the metal precursor salt, and a reducing agent is added, and a pyrolysis reduction reaction is carried out under the protection of an inert gas to obtain core-shell structure nanoparticles; wherein, the temperature of the pyrolysis reduction reaction is 200- 230℃, the time is 0.5-1h;

[0041] The core-shell structure nanoparticles are supported on a carrier, and after post-treatment, a catalyst for a fuel cell is obtained.

[0042] In this example, a smaller CeO is first synthesized 2 The metal nanoparticles are used as the core, and then the mixed solution of metal precursor salt is configured, and the CeO 2 Nanoparticles and a redu...

Embodiment 1

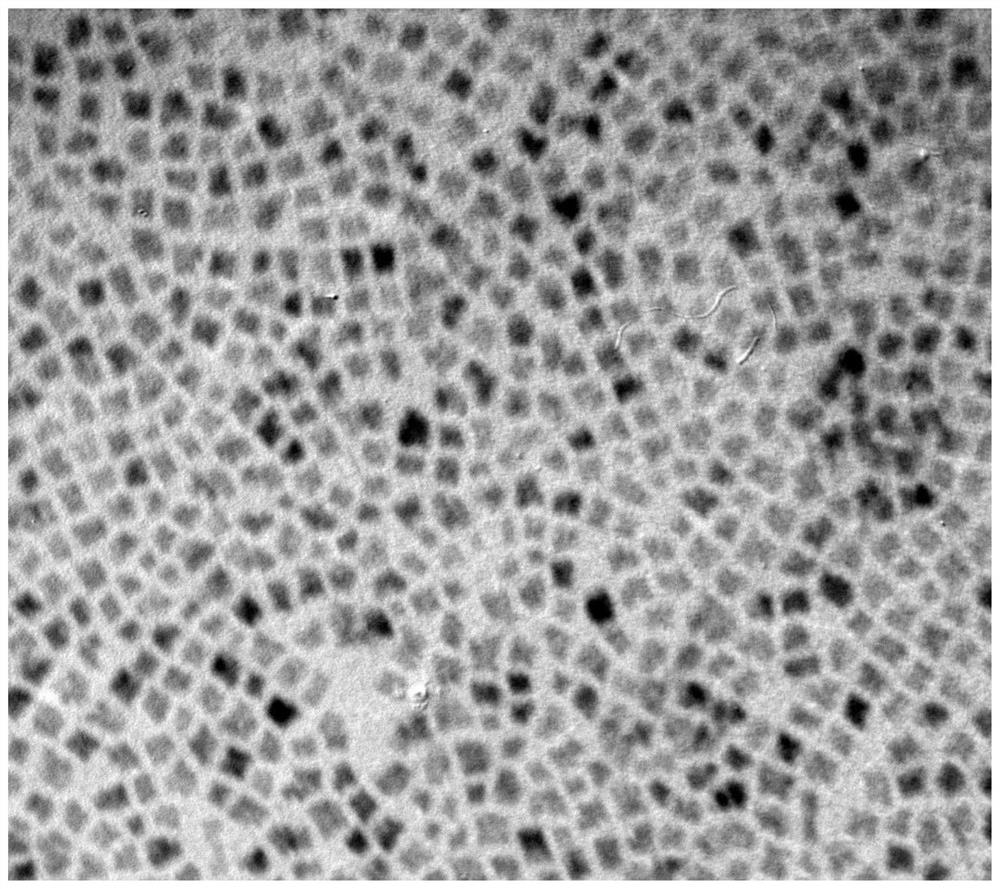

[0064] Step S1: Synthesis of CeO 2 Nanoparticles, including:

[0065] Step S11: under mild nitrogen protection, mix and stir 170 mg of cerium nitrate, 15 mL of octadecene and 5 mL of oleylamine, slowly heat to 260° C. for 20 min and keep the temperature for one hour to obtain a first mixed solution;

[0066] Step S12: cooling the mixed solution obtained in step S11, centrifuging with ethanol to obtain CeO 2 Nanoparticles, the CeO 2 The nanoparticle size is 10 nm.

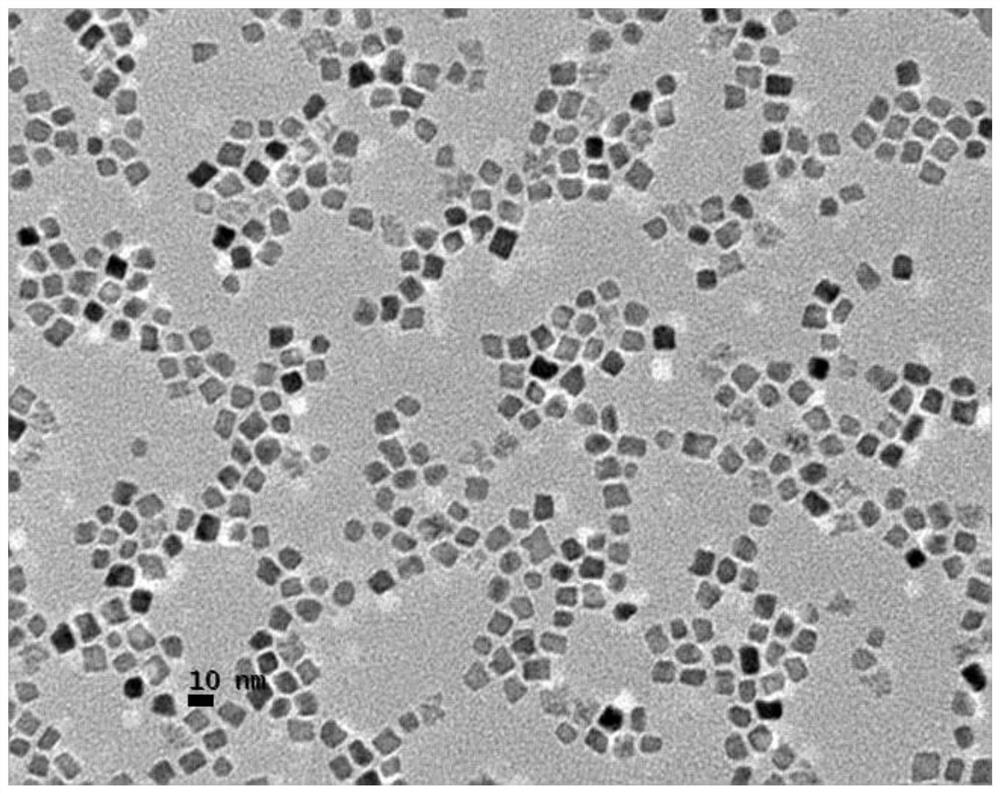

[0067] Step S2: Using Pt(acac)2 as a precursor, a mixed solution of metal precursor salts is prepared, and CeO 2 Nanoparticles are added to it, and the reducing agent Fe(CO) is added 5 (Pentahydroxy iron), carry out a pyrolysis reduction reaction under the protection of an inert gas to obtain core-shell structure nanoparticles, specifically including:

[0068] Step S21: Dissolve 100 mg of sodium oleate in 12 mL of ODE (Octadecene, octadecene) solution under nitrogen protection, stir and heat it to 180°C, then l...

Embodiment 2

[0084] The difference between this embodiment and Embodiment 1 is that the CeO 2 The particle size of the nanoparticles is 18nm, including:

[0085] Step S1: Synthesis of CeO 2 Nanoparticles;

[0086] Step S11: under mild nitrogen protection, mix and stir 170 mg of cerium nitrate, 10 mL of octadecene and 1.5 mL of oleylamine, slowly heat to 260° C. for 20 min and keep the temperature for one hour to obtain a first mixed solution;

[0087] Step S12: cooling the mixed solution obtained in step S11, centrifuging with ethanol to obtain CeO 2 nanoparticles.

[0088] Step S2: Using Pt(acac)2, sodium oleate, ODE, OAM and OA solution as raw materials to prepare a mixed solution of metal precursor salts, CeO 2 Nanoparticles are added to it, and the reducing agent Fe(CO) is added 5 (Pentahydroxy iron), under the protection of an inert gas, a pyrolysis reduction reaction is carried out to obtain core-shell structure nanoparticles;

[0089] Step S3: the core-shell structure CeO 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com