Mining truck and regenerative braking strategy therefor

A technology for regenerative braking and trucks, applied in trucks, control drives, electric braking systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

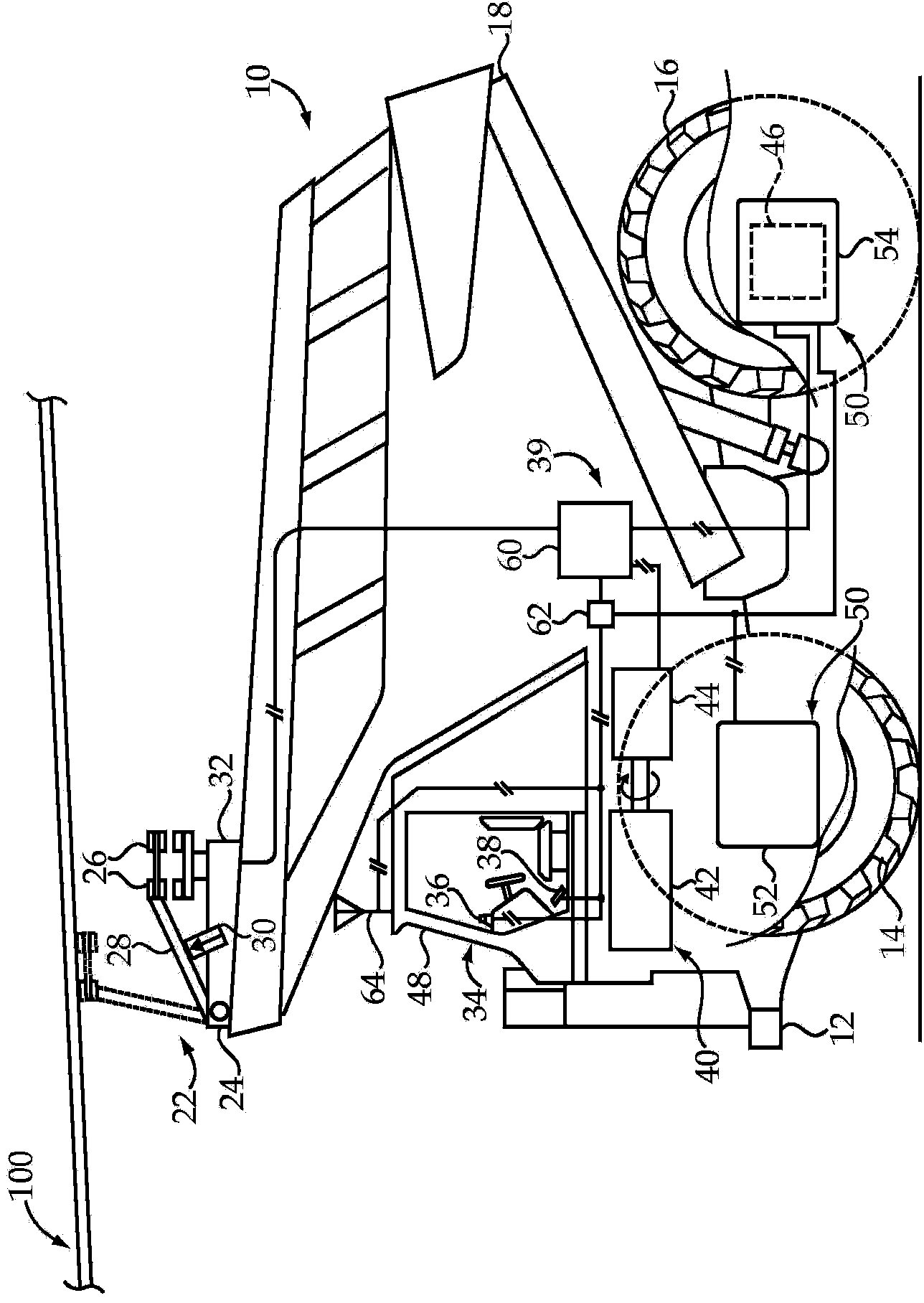

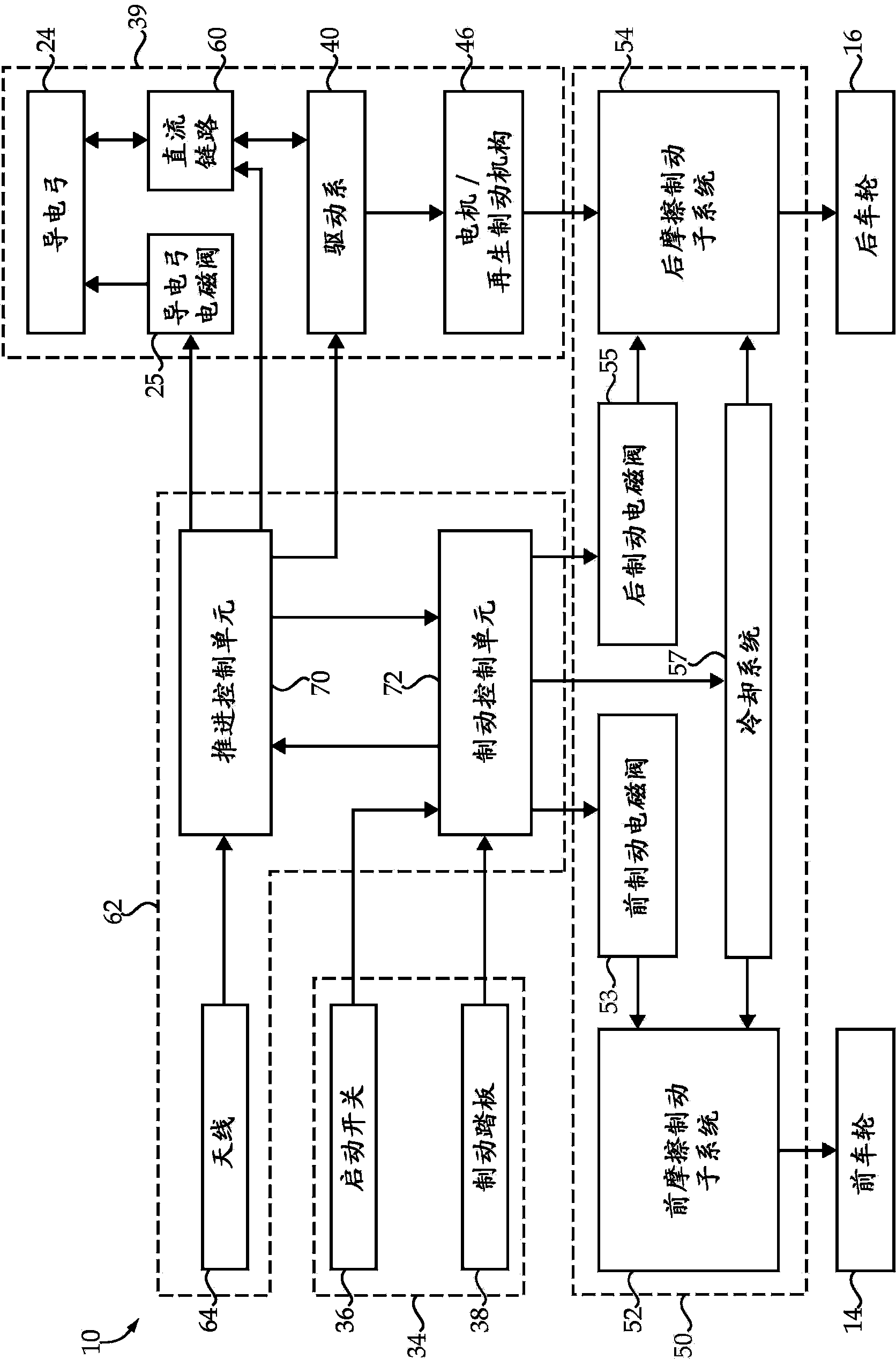

[0015] refer to figure 1 , which shows a trolley assist capable mining truck 10 according to one embodiment. The mining truck may include a frame 12 having a set of front ground engaging wheels 14 and a set of rear ground engaging wheels 16 coupled to the frame 12 . In the illustrated embodiment, a set of two front wheels 14 configured to steer the truck 10 and a set of two pairs of rear wheels 16 on one axle for propelling the truck 10 are provided, although the invention is not limited thereto. The bed 18 is coupled to the frame 12 and can be tilted between a lowered position as shown and a raised position to dump material within the bed 18 in a conventional manner. The mining truck 10 may also include a propulsion system 39 of which the ground contact wheels 14 and / or 16 may be part, the system 39 including a drive train 40 having an internal combustion engine 42 and a generator 44 providing electrical power via the internal combustion engine 42 . In a practical implement...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap