Forming device and method for high-precision hollow component

A hollow component, high-precision technology, applied in the direction of forming tools, hollow objects, and other household appliances, to achieve the effects of eliminating inhibition, improving mechanical properties, and ensuring uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A method for forming a high-precision hollow member, the technical solution of which is to include the following steps:

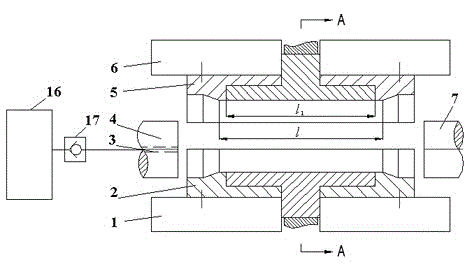

[0042] Step 1: Die preparation, first design the corresponding lower die 2, upper die 5, left punch 4 and right punch 7 according to the shape of the component, the above is the same as the prior art, and will not be repeated here. The lower mold 2 is connected to the lower workbench 1 of the press, the upper mold 5 is connected to the upper slider 6 of the press, and a check valve 17 is installed between the left punch 4 and the high pressure source 16;

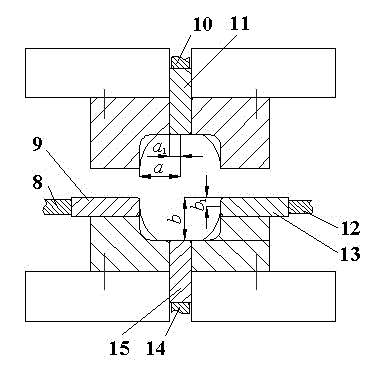

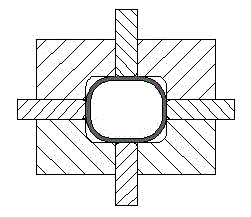

[0043] Step 2: Install the anti-deformation mechanism 9, 11, 13, 15 on the mold, one end of the anti-deformation mechanism faces the mold cavity, and the other end extends out of the mold cavity, and is connected with the ejection mechanism 8, 10, 12, 14 of the press . The main point is the width of the anti-deformation mechanism a 1 about 0.1 a ~0.3 a , b 1 about 0.1 b ~0.3 b ,length l1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com