Transfer printing film, transfer printing device and transfer printing method

A transfer film and transfer printing technology, applied in the direction of transfer printing, rotary printing machine, copying/marking method, etc., can solve the problem that the film cannot be reused, and achieve the effect of non-reusable and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

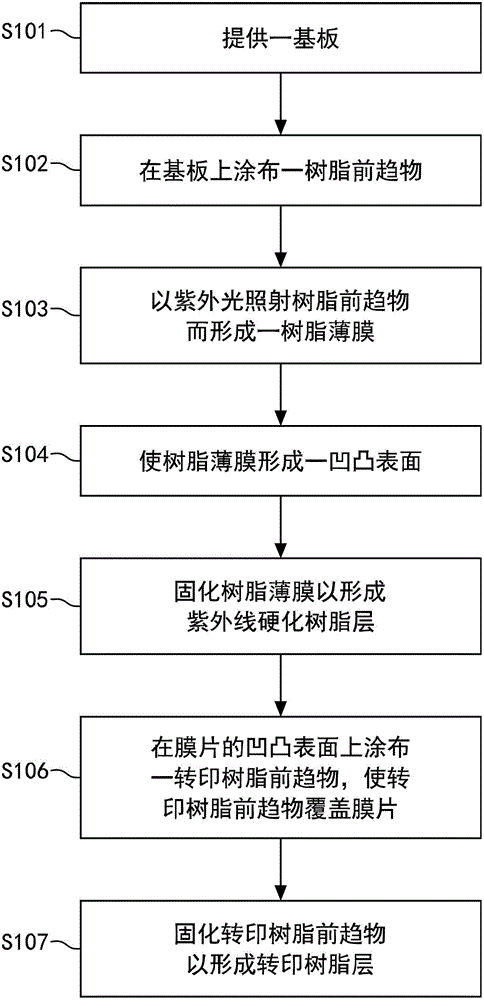

[0030] The detailed features and advantages of the present invention are described in detail below in the embodiments, which are sufficient to enable those skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the contents, claims and drawings disclosed in this specification, this The related objects and advantages of the present invention can be easily understood by those skilled in the art. The following examples further describe the concepts of the present invention in detail, but do not limit the scope of the present invention in any way.

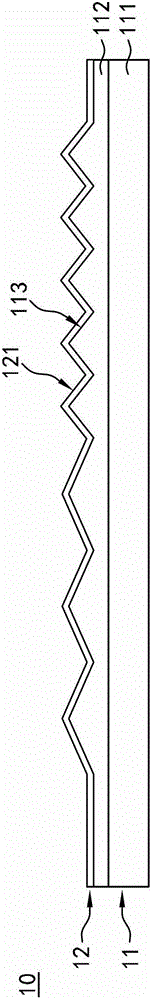

[0031] First, please refer to figure 1 , figure 1 It is a schematic diagram of a transfer film disclosed according to an embodiment of the present invention. The transfer film 10 includes a film 11 and a transfer resin layer 12 .

[0032] The diaphragm 11 includes a substrate 111 and an ultraviolet curing resin layer 112 . The material of the substrate 111 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com