Rail-type reciprocating conveying trolley

A reciprocating, transport vehicle technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of consuming manpower and material resources, low efficiency, time-consuming and laborious, and achieve the effect of saving manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

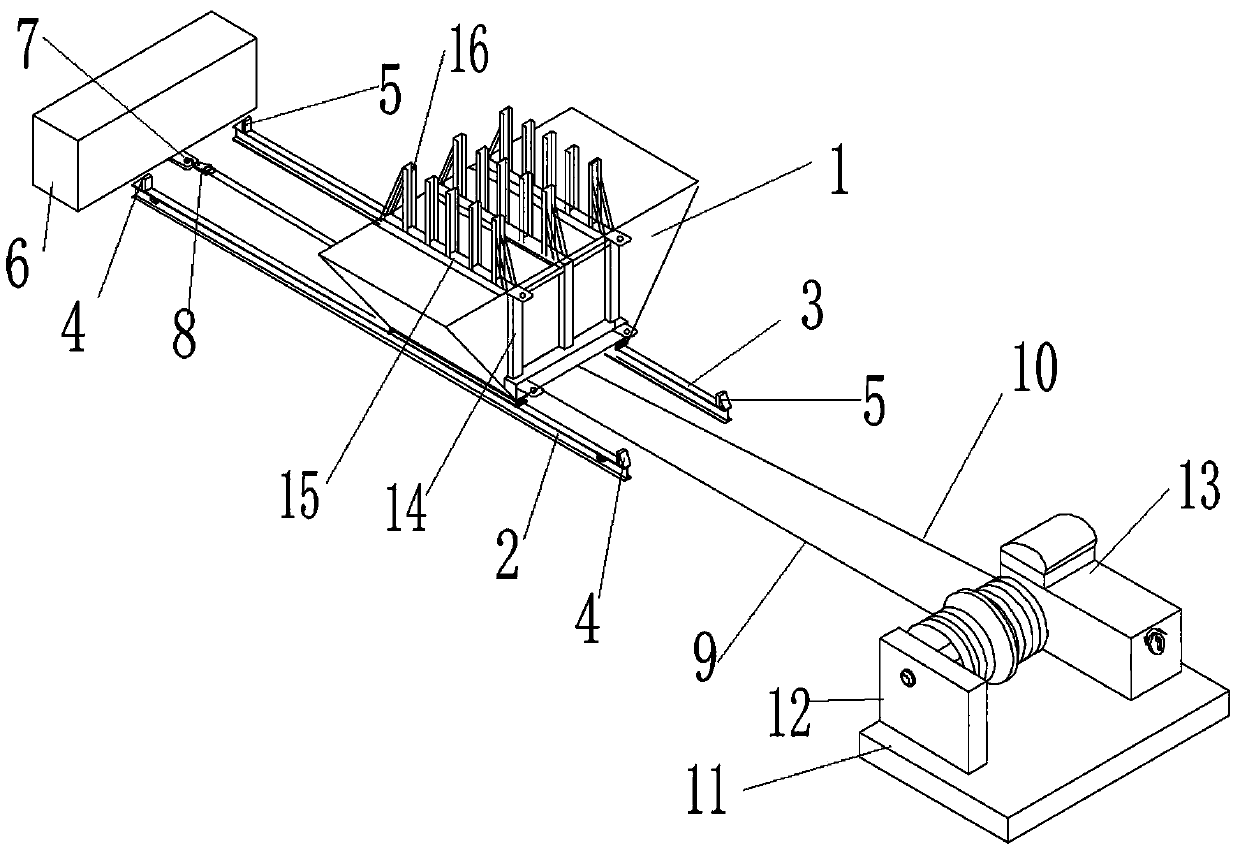

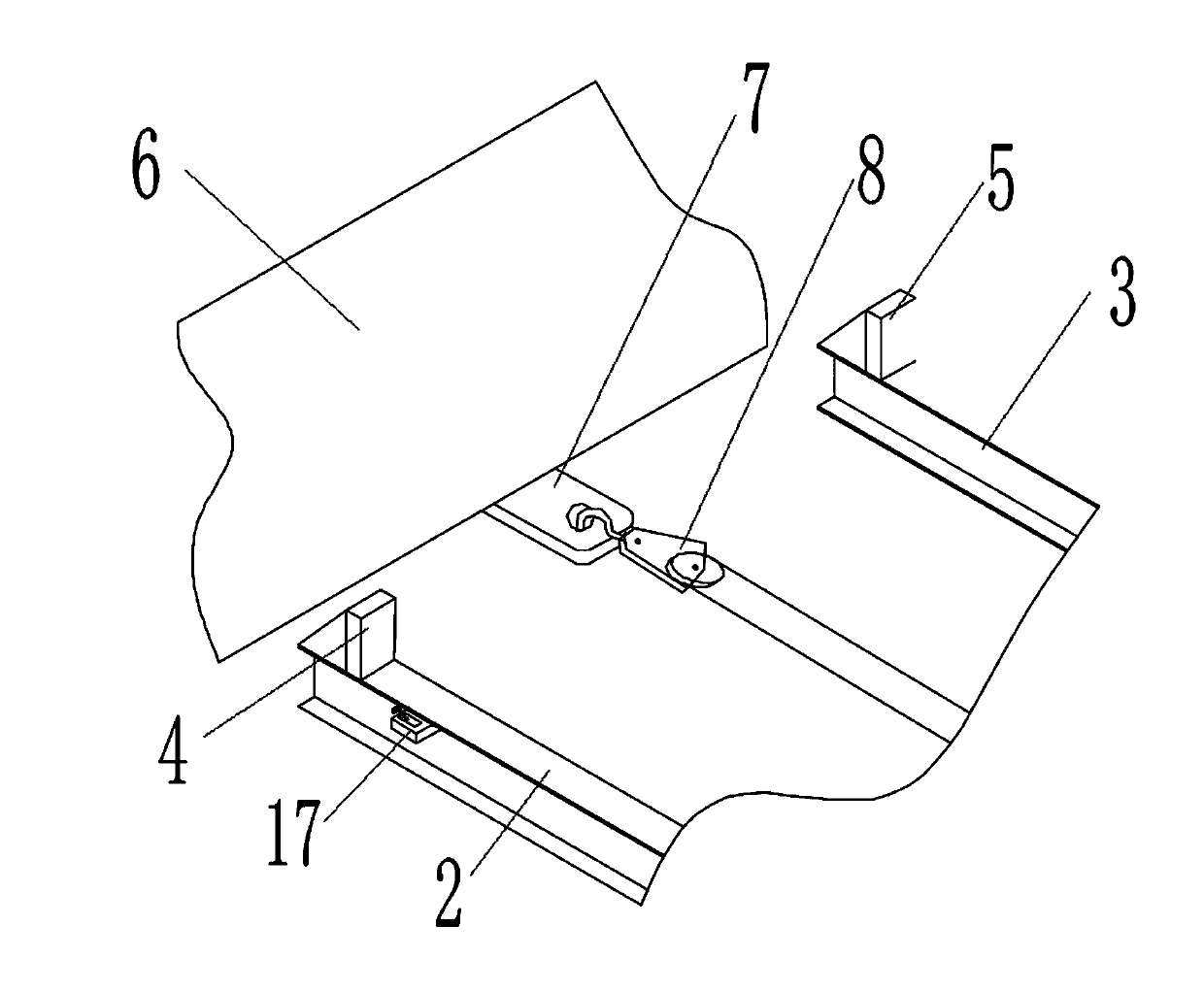

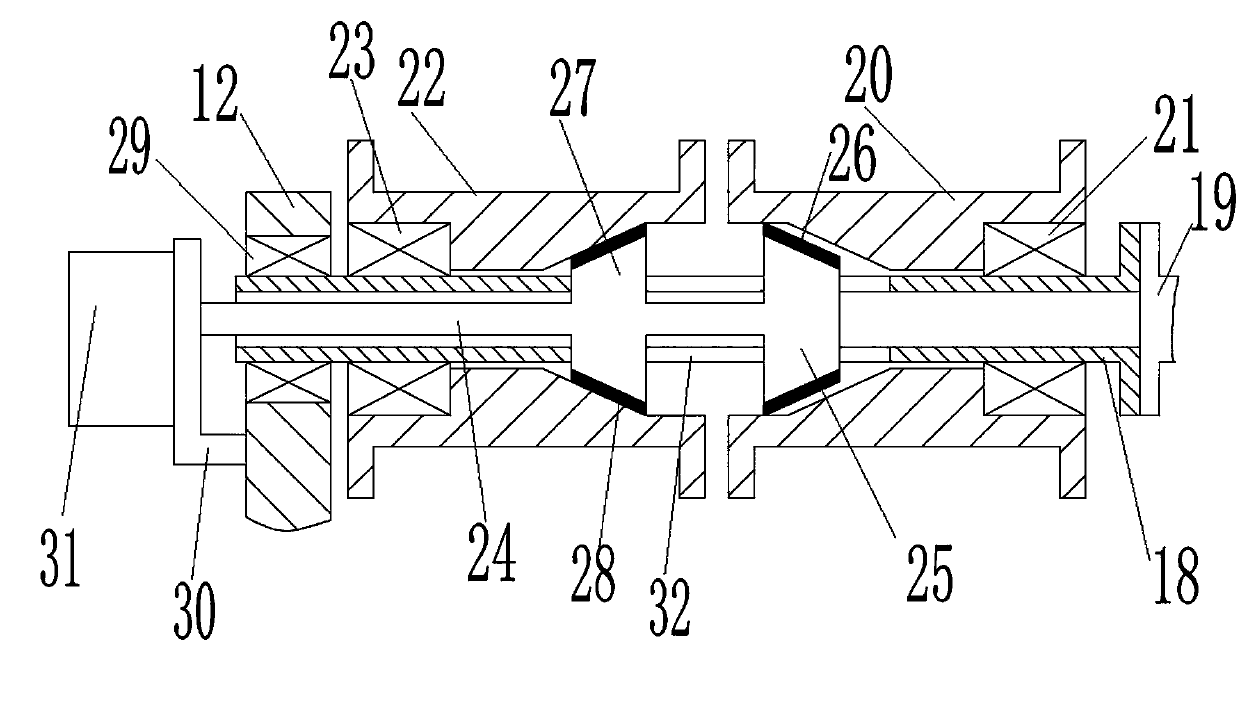

[0016] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0017] This track reciprocating transport vehicle includes a left guide rail 2 and a right guide rail 3 fixed on the ground parallel to each other, a trolley 1 set on the left guide rail 2 and the right guide rail 3 through wheel rolling, and a trolley fixed on the left guide rail 2 and the right guide rail 3 The fixed anchor point 6 at the rear end, the pulley 8 installed on the fixed anchor point 6 through the ear seat 7, and the power device arranged at the front end of the left guide rail 2 and the right guide rail 3, one end of the steel wire rope I 9 is fixed on the front side of the trolley 1, and the other One end is fixed on the power device, one end of the wire rope II 10 is fixed on the rear side of the trolley 1 around the pulley 8, and the other end is fixed on the power device, and the power device drives the wire rope I 9 or the wire rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com