Space cam for slot machine transmission mechanism

A technology of transmission mechanism and space cam, which is applied in the direction of driving device, metal processing machinery parts, metal processing equipment, etc., can solve the problems of poor work reliability, complex structure, inconvenient maintenance, etc., and achieve convenient and fast installation, high work reliability, The effect of simplifying the transformation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

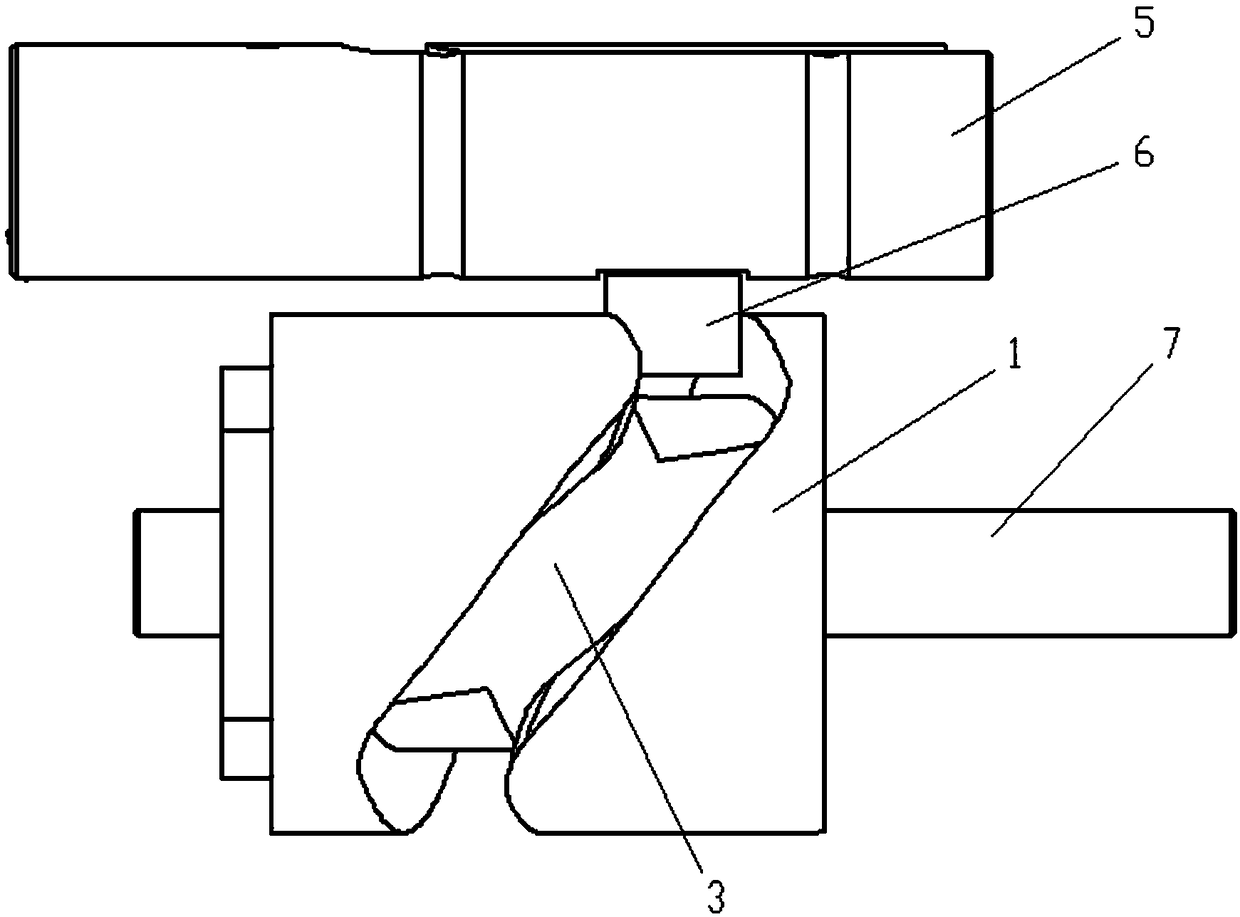

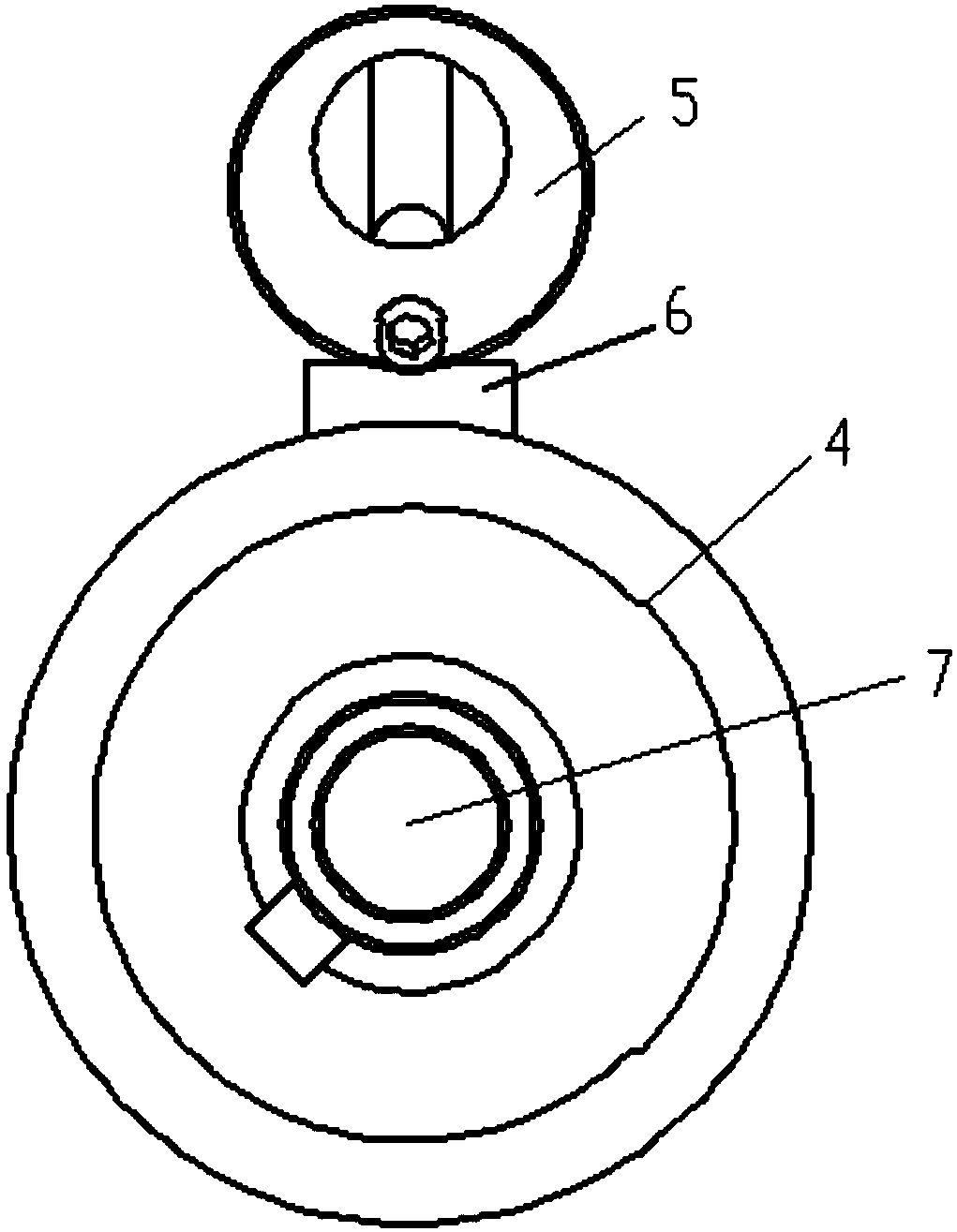

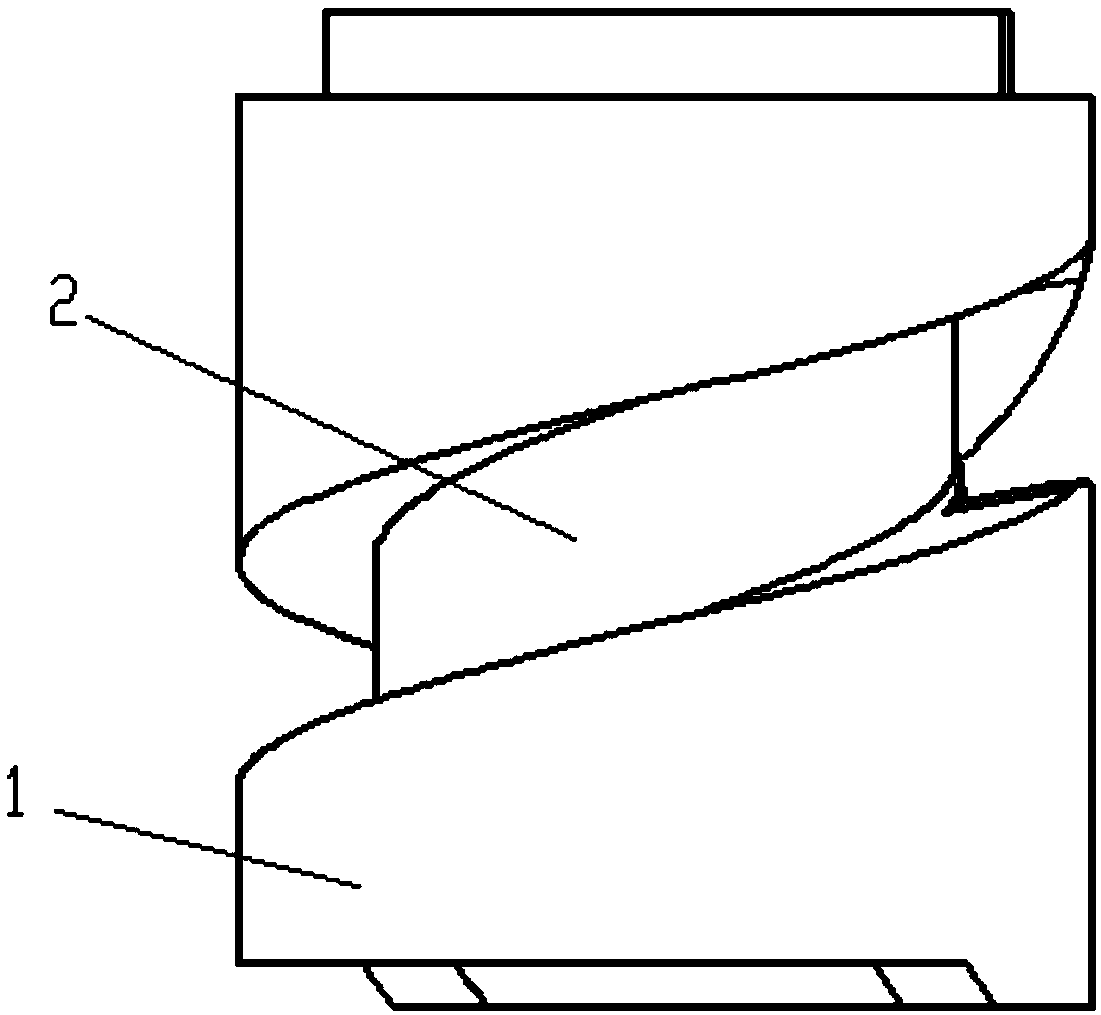

[0014] Attached below Figure 1-3 An embodiment of the present invention is described.

[0015] The space cam used in the slot machine transmission mechanism has a cam body 1, and the outer peripheral wall of the cam body 1 is formed with a process spiral groove 2 and a return spiral groove 3, and the process spiral groove 2 and the return spiral groove 3 The direction of rotation is opposite and connected at the intersection of the two ends to form a closed-loop structure. The outer peripheral wall of the step at one end of the cam body 1 is in contact with the cam follower I installed on the shaft seat of the tool bar, and the outer circumference of the step at one end of the cam body 1 The circumferential wall is shaped on an arc-shaped protrusion 4, and the tool bar shaft seat is provided with a tool bar shaft 5 that can move along the length direction of the tool bar shaft seat, and the process spiral groove 2 and the return spiral groove 3 are fixed to the knife bar shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com