Road ramming machine for civil engineering

A technology of civil engineering and earth rammer, which is applied in the field of civil engineering, can solve the problems that the corners cannot be compacted well and increase the repair work, and achieves the effect of good compaction effect and reduced repair workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

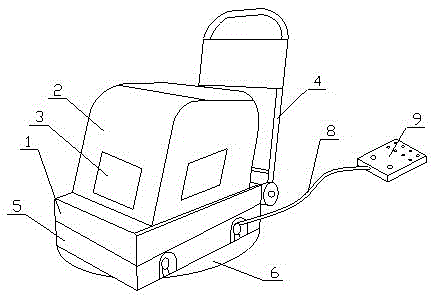

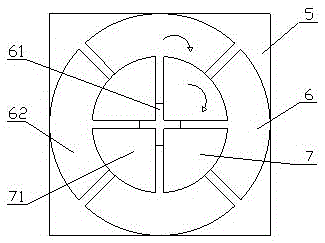

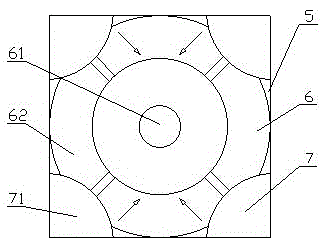

[0017] like Figure 1 to Figure 4 The shown road ramming machine for civil engineering includes a base 1, the upper surface of the base 1 is provided with a motor, the periphery of the motor is covered with a motor protection cover 2, and a plurality of cooling windows are opened on the side wall of the protection cover 2 3. The rear side of the base 1 is hinged with a push handle 4, the lower surface of the base 1 is provided with a square control panel 5, and the lower surface of the control panel 5 is provided with a circular main rammed earth disc 6, and the main rammed earth disc 6 A circular installation hole 61 is opened at the center, and a sub-rammed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap