A construction method of full width segment

A construction method and wide-shaped technology, which can be used in ship construction, ship design, ships, etc., can solve the problem of difficult construction of full-width sections, and achieve the goal of improving construction efficiency, reducing repair workload, and reducing the problem of upturning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

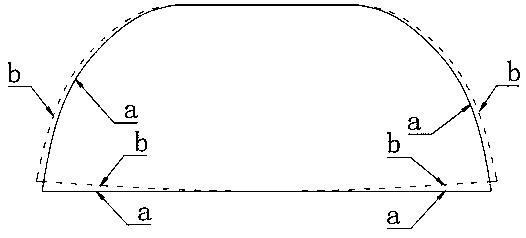

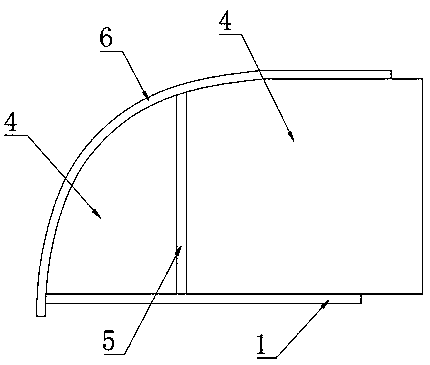

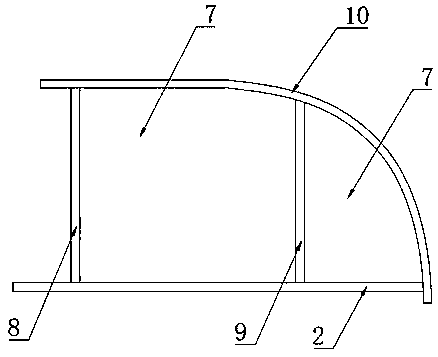

[0030] Embodiment: a kind of construction method of full-width type segment, such as Figure 2 to Figure 5 shown, including the following steps:

[0031] Step 1. Divide the full-width segmented bottom plate into the first bottom plate 1 and the second bottom plate 2 according to the existing plate seams. the most recent weld;

[0032] Step 2: Fabricate the tire frame 3, lay the first bottom panel on the tire frame, fix the first bottom panel on the tire frame 3, and perform tack welding on the gaps between the first bottom panels to form the first bottom panel 1 , laying the second base plate assembly on the tire frame, fixing the second base plate assembly on the tire frame 3, tacking the gap between the second base plate assembly to form the second base plate 2;

[0033] Step 3. Install the first rib 4 on the first bottom plate 1. The installation sequence of the first rib 4 in the left and right direction of the ship is to install gradually from the side close to the cent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap