A method for repairing inner heat insulation layer

A technology of heat insulation layer and heat insulation pad, which is applied in the direction of aerospace vehicle heat protection device, aerospace safety/emergency device, fuselage insulation, etc., and can solve the difficulty of removing and laying the inner heat insulation layer Problems such as poor thermal performance and easy falling off of the repaired structure achieve the effect of reducing the repairing workload, making repairs convenient, and improving the strength and appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

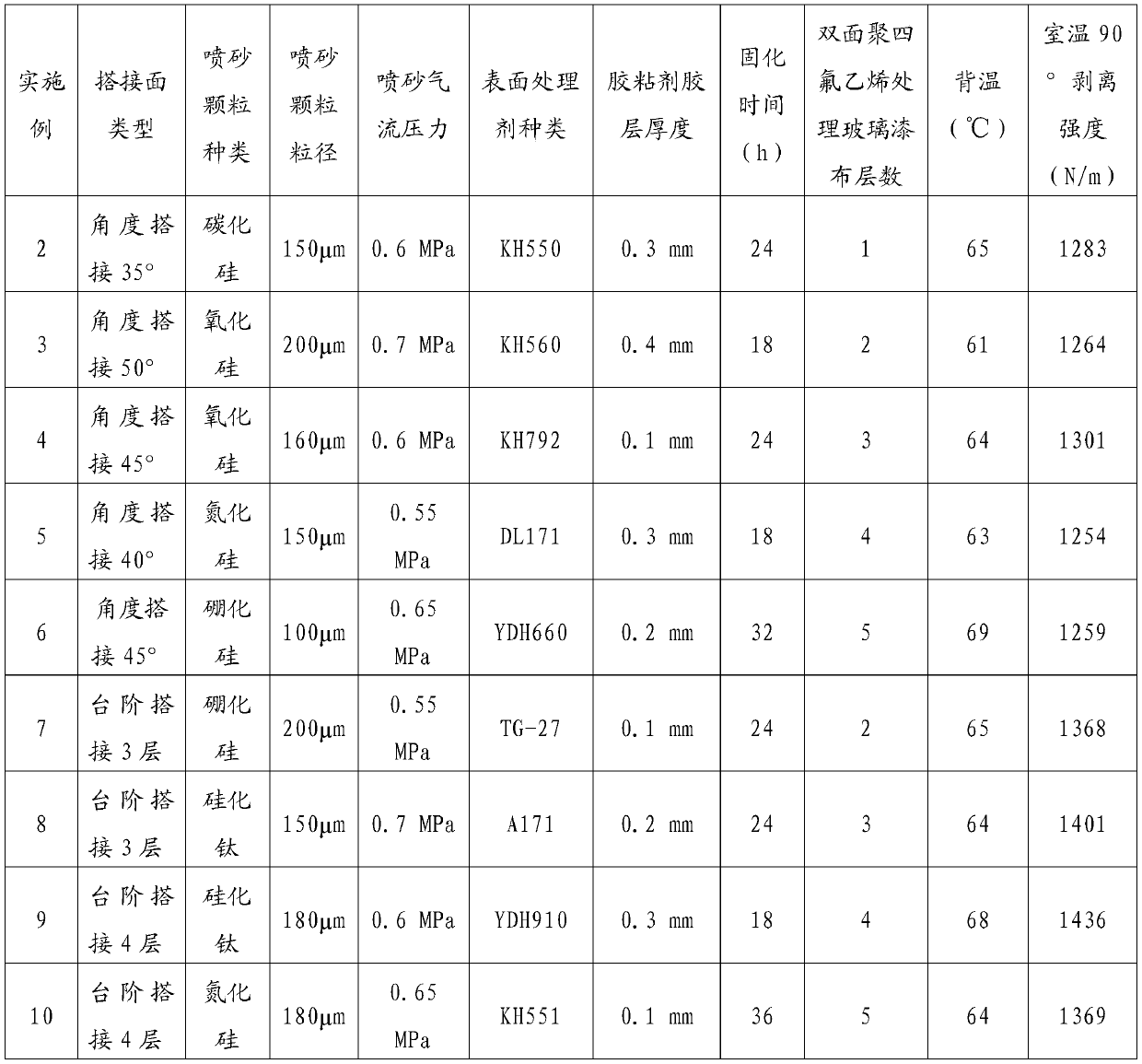

Examples

Embodiment 1

[0046]Completely clean the heat insulation layer at the damaged position, and remove the residual adhesive layer on the metal surface. The thickness of the heat insulation layer is 13mm, and the damaged length is 18mm, and the damaged width is 10mm. Metal surfaces are grit blasted and then wiped clean with acetone. After drying, apply surface treatment agent KH550 on the metal surface and the overlapping surface, and then apply silicone rubber adhesive, the thickness of the adhesive layer is 0.2mm. Cut the heat insulation material for filling according to the size and shape of the damaged part and the overlapping method, and fill it in the damaged part, and then use the gap heat insulation material to heat-insulate and seal the gap between the heat insulation layers. The gap heat insulation material is made of silicone rubber Adhesive, glass hollow microspheres with a particle size of 75 μm and glass fibers with a diameter of 7 μm and a length of 5 mm, with a mass ratio of 10...

Embodiment 7

[0050] Completely clean the heat insulation layer at the damaged position, and remove the residual adhesive layer on the metal surface. The thickness of the heat insulation layer is 21mm, and the damaged length is 35mm, and the damaged width is 40mm. When repairing, the step lap method is used, and the lap joint surface is repaired into three lap steps. The inclined face joint method is used, and the thickness of the step is 6mm. , the width is 12mm, the angle of the step slope is 30°, the metal surface is sandblasted with expanded silicon particles with a particle size of 200μm at an air pressure of 0.55MPa, and then wiped clean with acetone. After drying, apply the surface treatment agent TG-27 on the metal surface and the overlapping surface, and then apply the silicone rubber adhesive, the thickness of the adhesive layer is 0.1mm. Cut the heat insulation material according to the size and shape of the damaged part and the overlapping method, and fill it in the gap, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com