Comprehensive powder metallurgy sintering operation system and operation method

A technology of powder metallurgy and operation system, applied in the field of powder metallurgy sintering, can solve the problems of low high temperature sintering efficiency, prolonged sintering operation, low product quality, etc., and achieve the effect of improving metallurgical sintering efficiency, improving product quality, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] DESCRIPTION OF DRAWINGS The invention further.

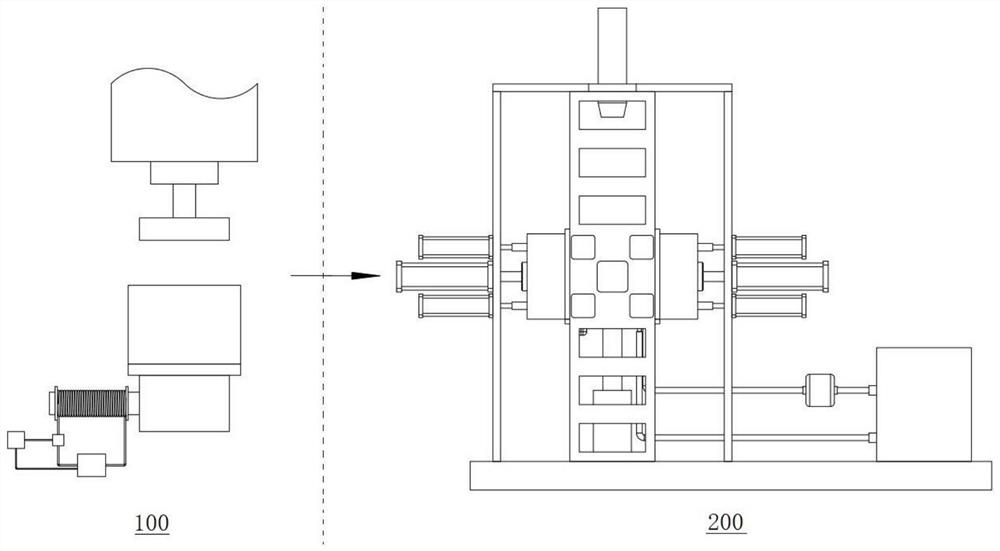

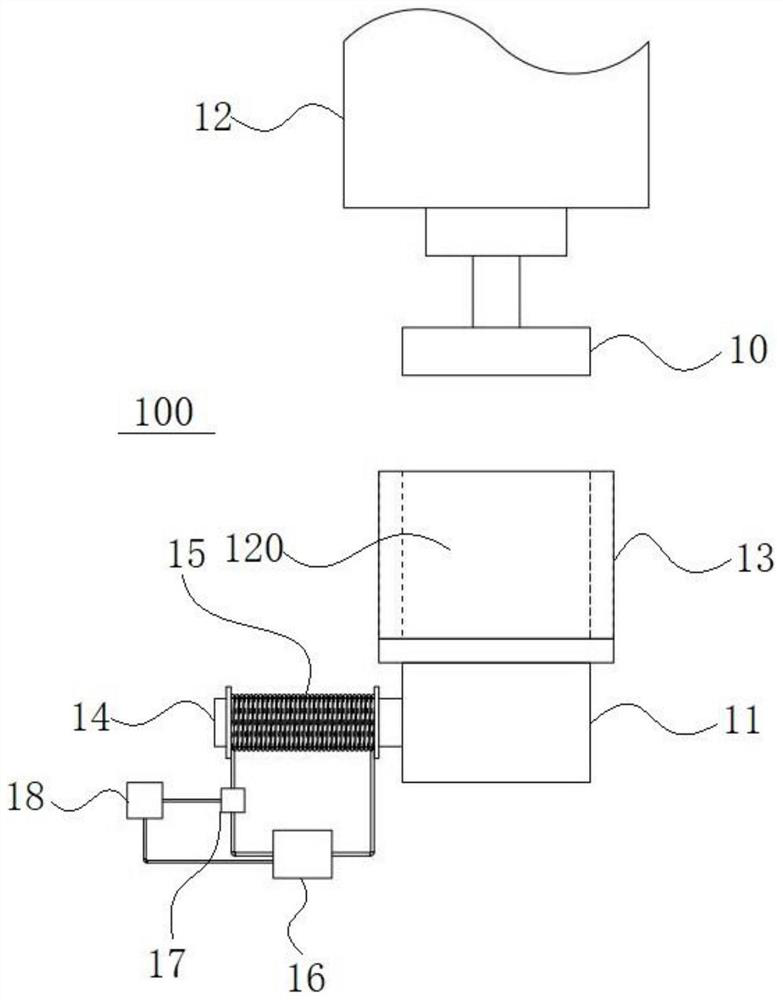

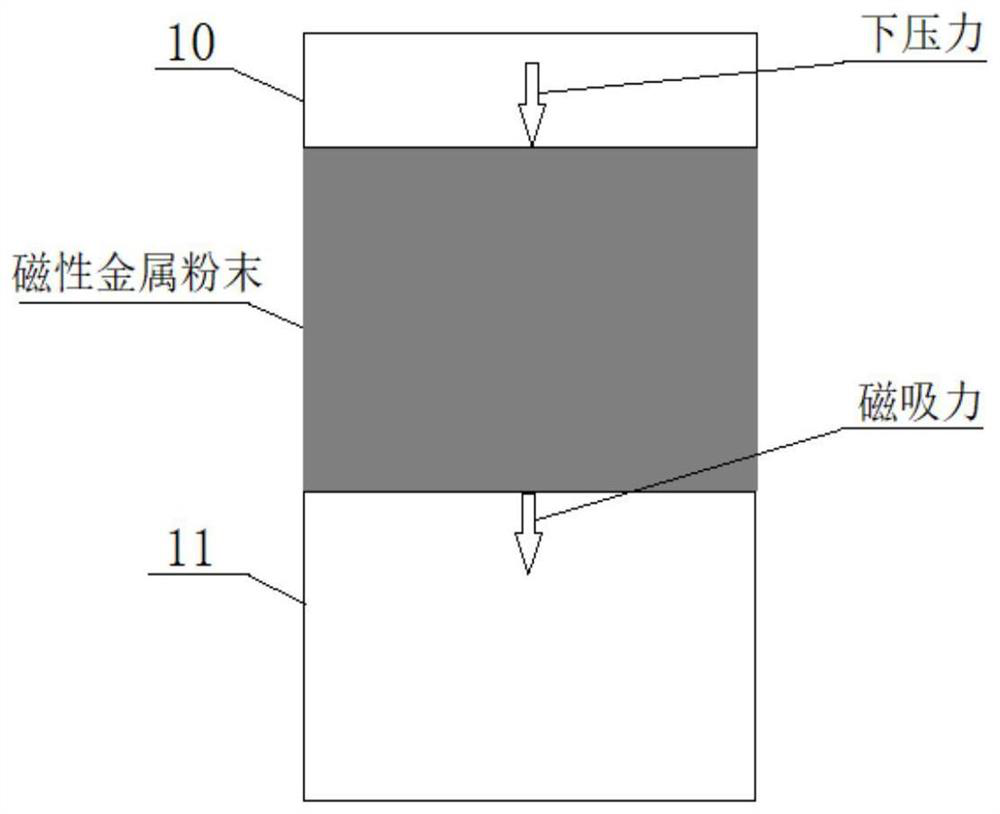

[0039] Append figure 1 Attachment figure 2 Attach image 3As shown in a powder metallurgy sintering integrated operating systems, including magnetic type powder forming apparatus 100, for which the magnetic metal powder press molding operations constituting the magnetic metallic powder-molded compact; the magnetic powder forming apparatus 100 of formula 10 comprises a compact, magnetic body 11 and the forming chamber 120, the pressure piece 10 is located above the molding chamber 120, the magnetic body 11 positioned below the forming chamber 120, the magnetic metal powder is spread on the molding cavity 120, the magnetic member 11 downward magnetic attraction magnetic metal powder, the magnetic metal powder compact depression 10 extends into the molding cavity 120. Before pressing the magnetic metal powder is pressed downwardly to move closer, reducing the gap between the particles, is more conducive to subsequent compaction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com