Angular-contact ball bearing capable of realizing grease repeatable-injection at outer ring

A technology of angular contact ball bearing and outer ring, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of scrapped bearings and angular contact ball bearings that cannot be re-filled with grease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

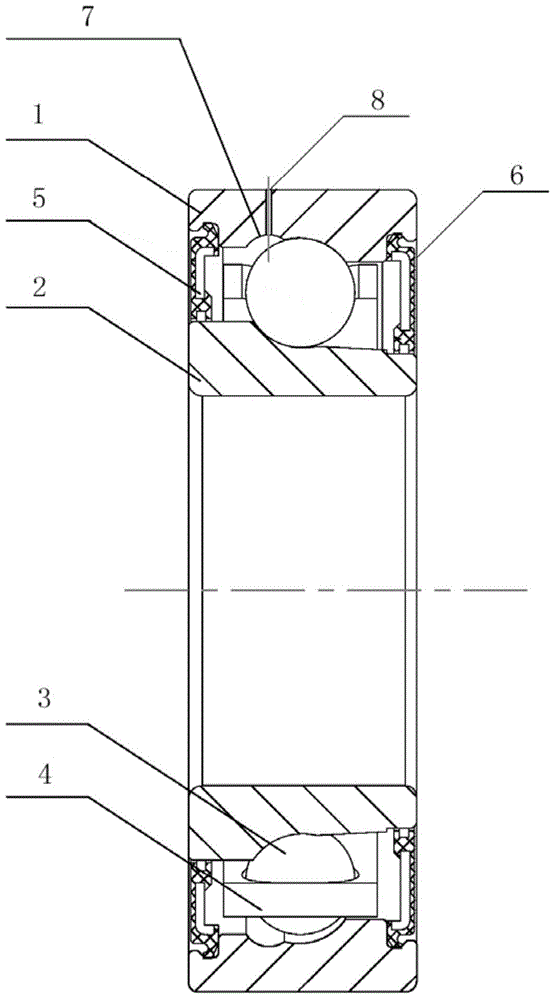

[0018] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the angular contact ball bearing with the outer ring that can be repeatedly greased according to the present invention will be given with reference to the accompanying drawings and preferred embodiments. , Structure, characteristics and effects are described in detail later.

[0019] See figure 1 As shown, figure 1 It is a schematic diagram of the assembly structure of an angular contact ball bearing with repeatable grease injection on the outer ring of the present invention.

[0020] The present invention proposes an angular contact ball bearing with repeatable grease injection on the outer ring, including: outer ring 1, inner ring 2, rolling elements 3, cage 4, first sealing ring 5, second sealing ring 6, and grease storage tank 7. Grease injection hole 8; among them:

[0021] Rolling elements 3 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com