Handle screwing type American valve joint

A technology of beautiful mouth and handle, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, functional valve type, etc., it can solve the problems such as the valve is not safe enough, the mouth body is broken and the root is broken, and it is laborious, so as to speed up the operation. Speed, uniformity and ease of force, to prevent the effect of breaking or even breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

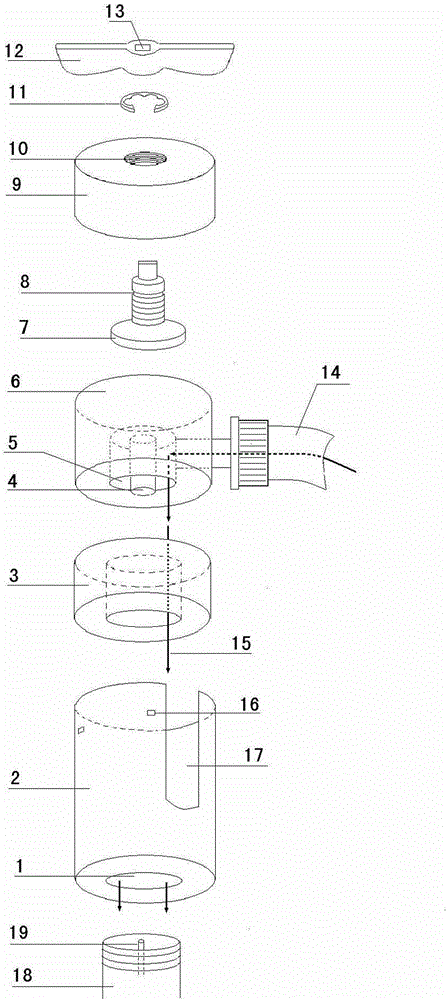

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the technical solution of the present invention, and provides detailed implementation methods and specific operating procedures, but the scope of protection of the present invention is not limited to the following embodiments. .

[0018] As shown in the figure, a rotary handle type American mouth joint is characterized in that it includes a joint body 2 and a joint upper cover 9 connected to the upper end of the joint body, and the bottom of the joint body 1 is provided with a valve body on the tire. 18 matched joint pipe body bottom hole 1, in the inner cavity of the joint pipe body 2, a cylindrical elastic ring 3, a cylindrical movable body and an adjustment bolt are arranged in sequence from bottom to top, and the upper end of the adjustment bolt After passing through the threaded hole of the joint upper cover 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com