Determination method for aluminium content in aluminium alloy alkaline chemical milling solution

A determination method and technology for aluminum alloys, which are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., to achieve the effect of ensuring quality, sufficient basis, and stabilizing the quality of milling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

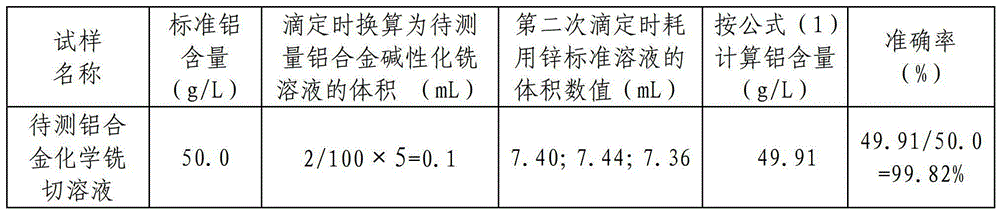

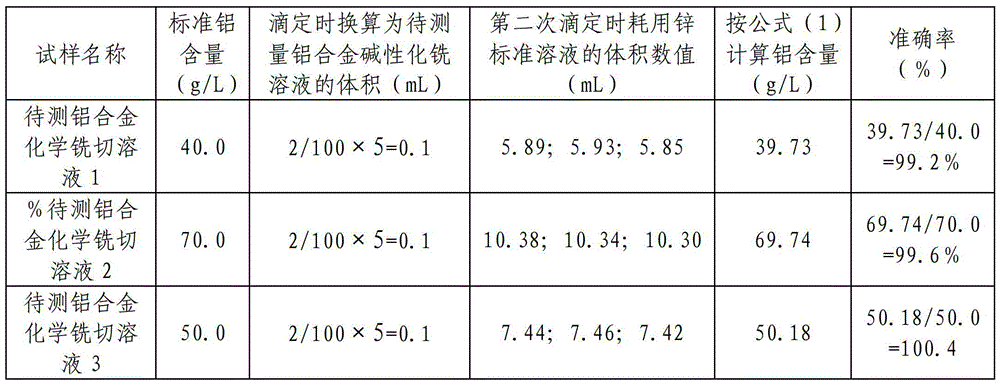

[0048] According to the test method determined in the present invention, aluminum alloy milling baths with standard aluminum contents of 40.0g / L, 70.0g / L, and 50.0g / L were respectively prepared and tested. The test data are shown in Table 1.

[0049] Determination test method embodiment test data of table 2 aluminum content

[0050]

[0051] It can be seen from Table 2 that the accuracy rate of the determination results is 99.2% to 100.4%, which proves that the analysis method is accurate and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com