Determination method for sodium hydroxide in alkaline chemical milling solution for aluminum alloy

A technology of sodium hydroxide and determination method, which is applied in the field of chemical cutting to achieve the effect of ensuring quality and stabilizing the quality of chemical milling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] According to the test method determined in the present invention, respectively prepare the aluminum alloy chemical milling groove liquid of standard sodium hydroxide content 220.0g / L, 180.0g / L, 200.0g / L and carry out implementation test, test data see table 1, table 2 and Table 3.

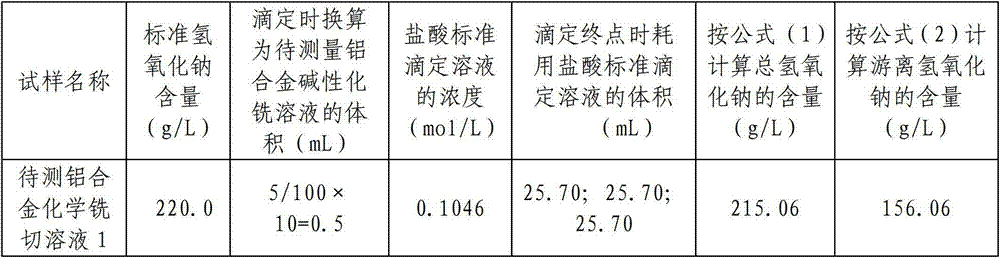

[0048] The mensuration test method embodiment verification test data 1 of table 1 sodium hydroxide content

[0049]

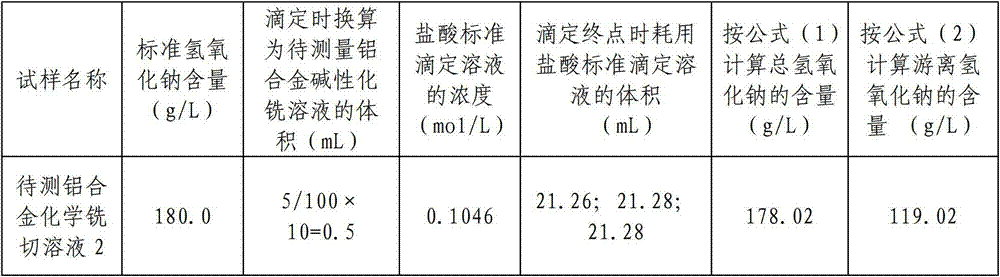

[0050] The determination test method embodiment verification test data 2 of table 2 sodium hydroxide content

[0051]

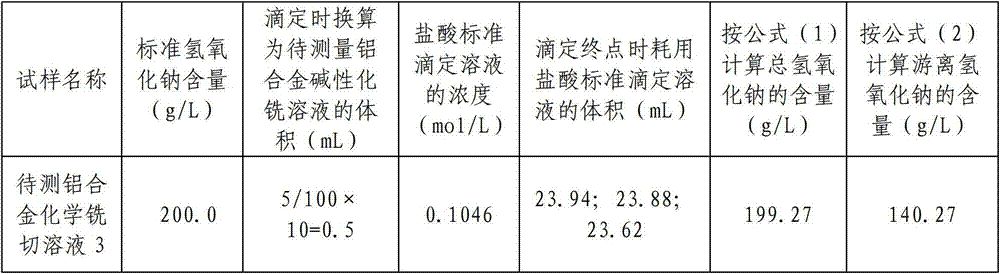

[0052] The determination test method embodiment verification test data 3 of table 3 sodium hydroxide content

[0053]

[0054] Seen from the above examples, the assay result of total sodium hydroxide is basically consistent with the addition amount, fully satisfying the test requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com