A cylindrical visual inspection equipment support that can rotate freely at multiple angles

A technology for appearance inspection and equipment support, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., and can solve problems such as visual defects of cylinder blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

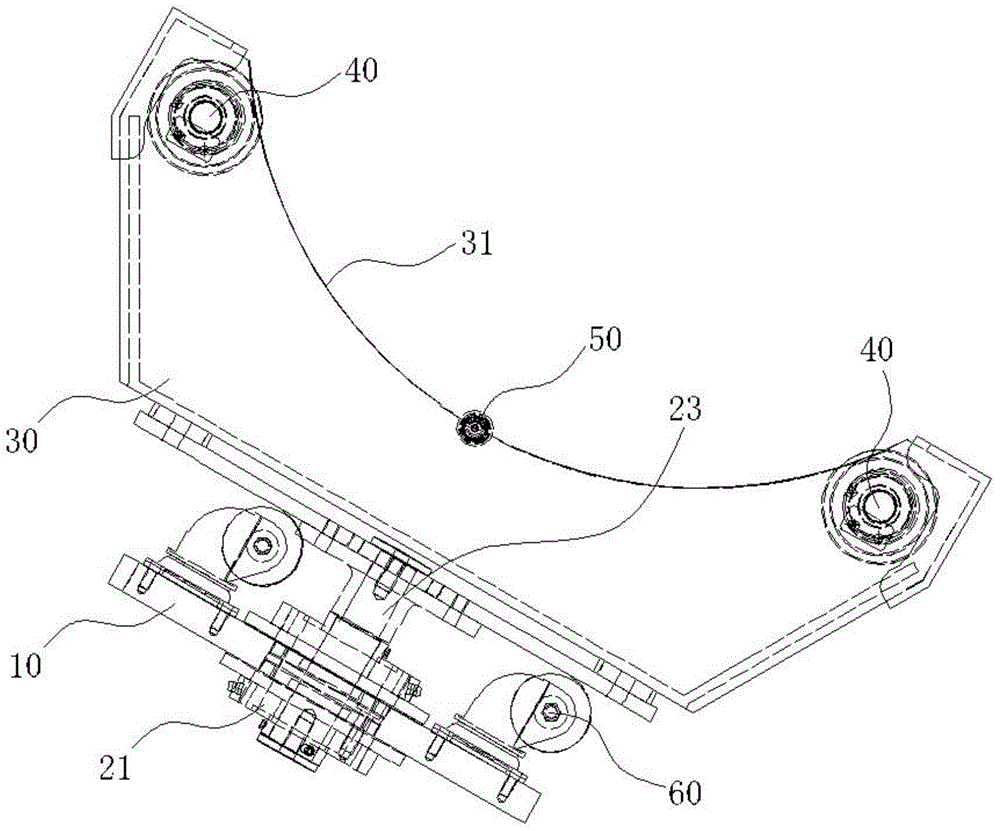

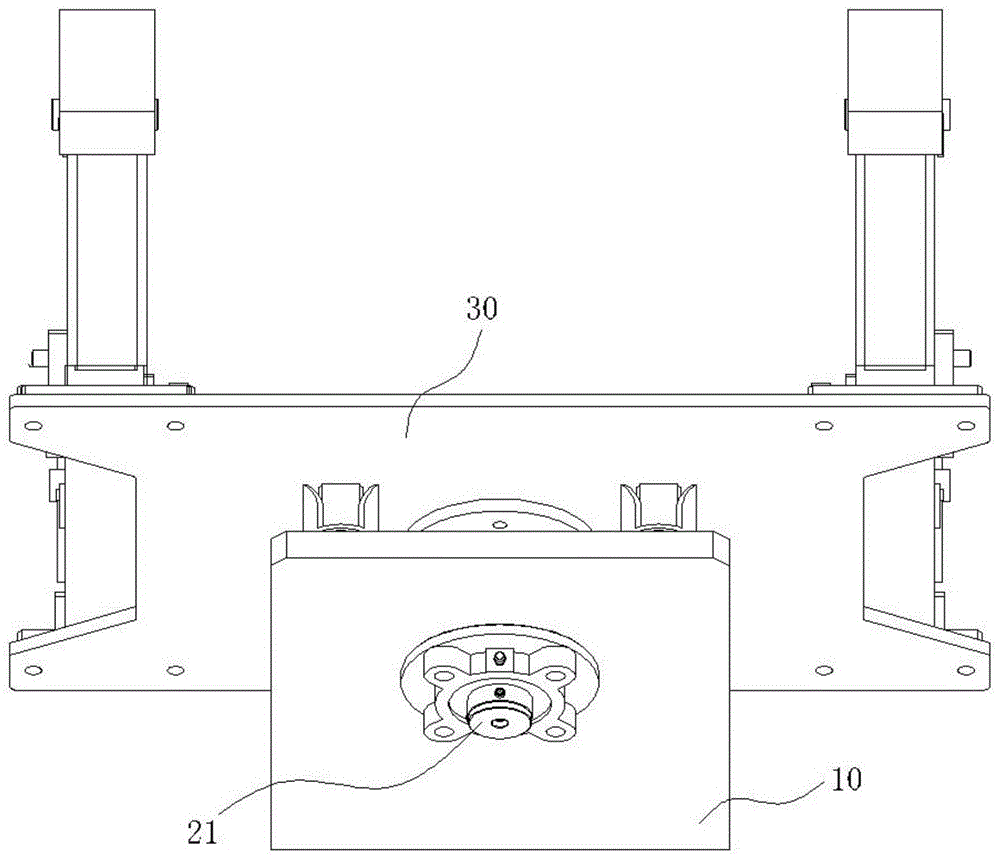

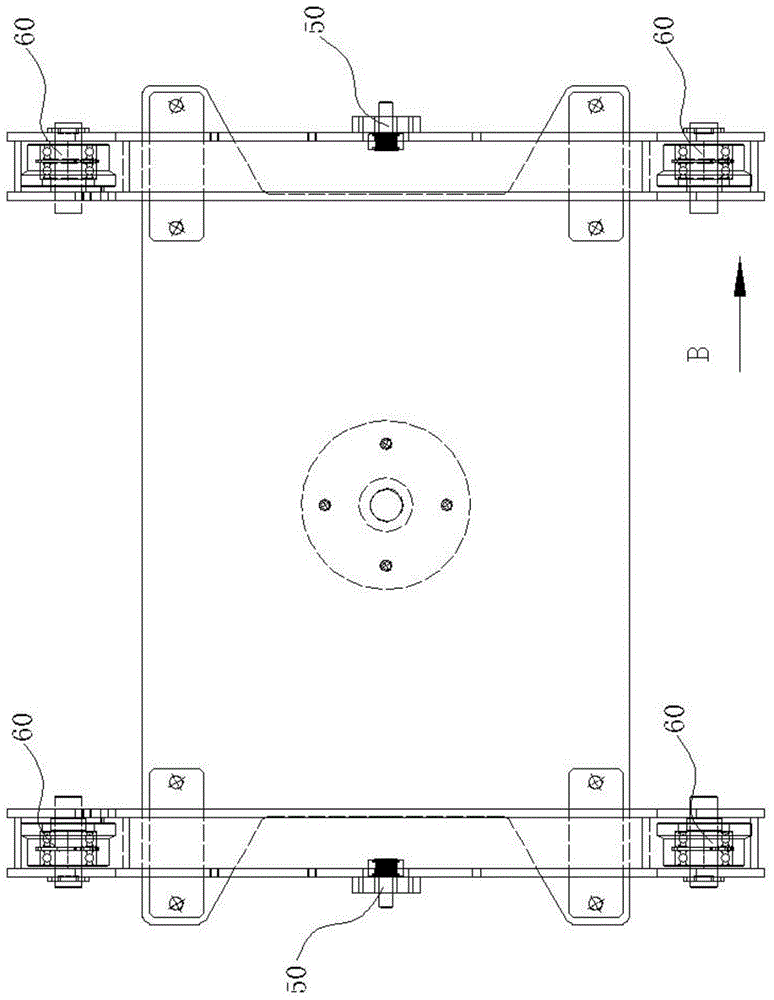

[0023] Such as Figure 1 to Figure 5 As shown, a cylindrical appearance inspection equipment bracket that can freely rotate at multiple angles includes a stand 10, a bearing unit 21 installed on the stand 10, a movable frame 30 installed above the stand 10 through the shaft and the bearing unit 21, A shaft seat is installed on the bottom plate of the movable frame 30, and the movable frame 30 is used to place cylindrical appearance inspection equipment, and the contact surface between the movable frame 30 and the cylindrical appearance inspection equipment is in the shape of an arc The contact portion 31 is provided with bearings 40 at both ends of the contact portion 31 and a bearing follower 50 is installed in the middle.

[0024] Casters 60 are also installed on the stand 10 , and the number of the casters 60 is four, which are distributed at the four corners of the stand 10 .

[0025] The bearing unit 21 on the platform 10 cooperates with the shaft to freely rotate the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com