Automatic feeder

A feeder, automatic technology, applied in animal feeding devices, program control in sequence/logic controllers, animal husbandry, etc., can solve the problems of feed backlog, overflow, waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

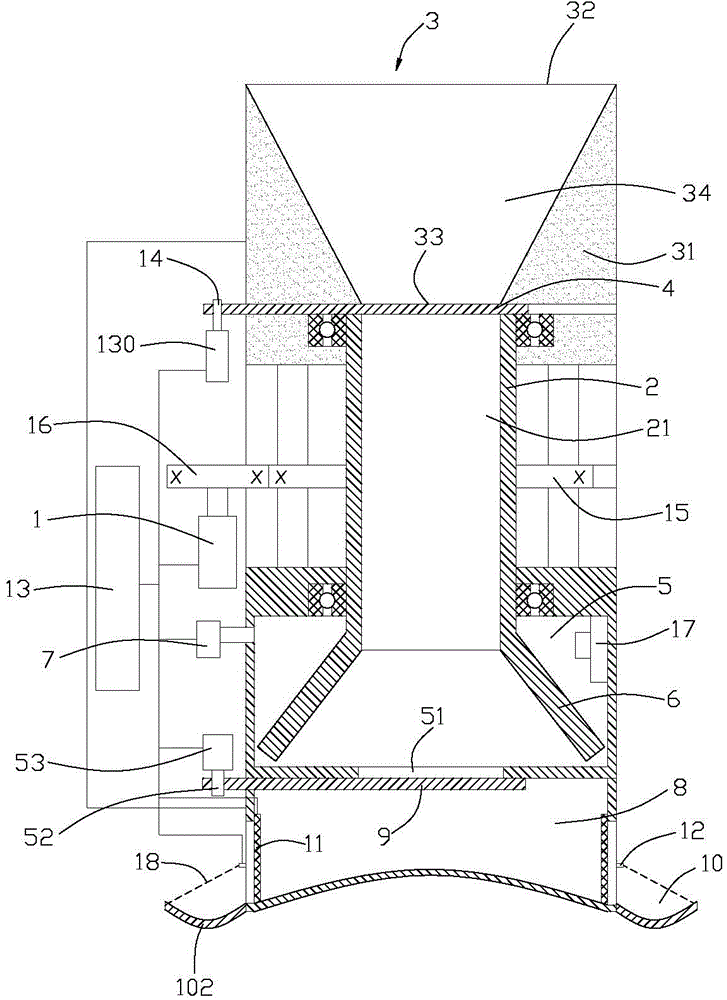

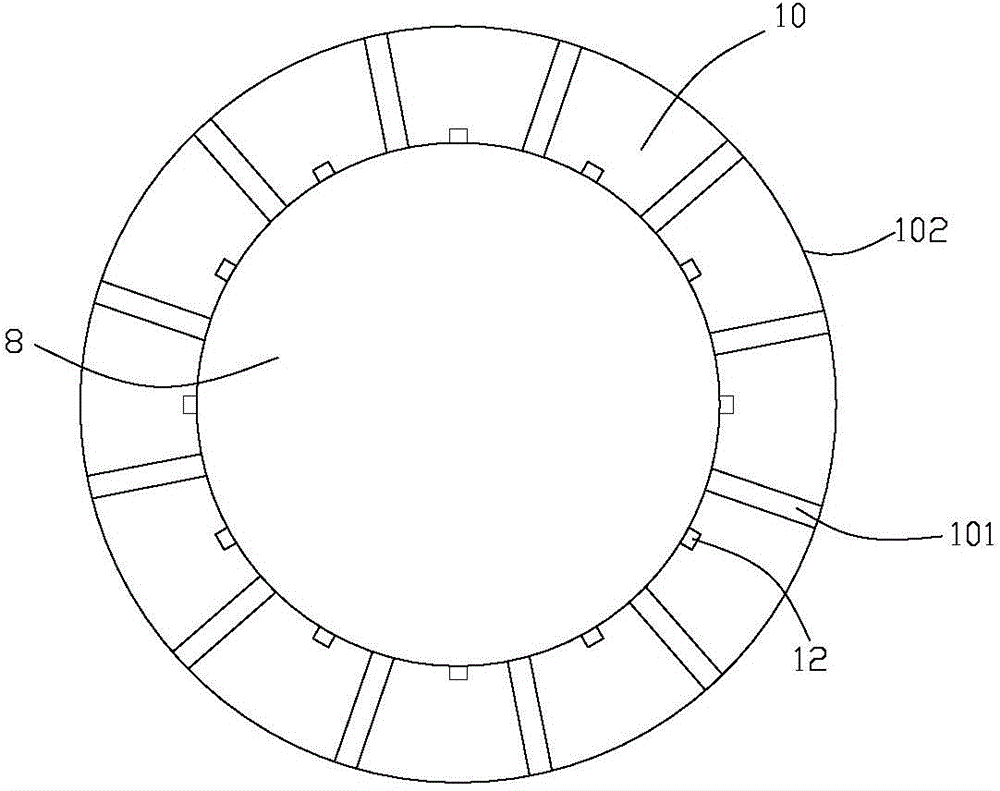

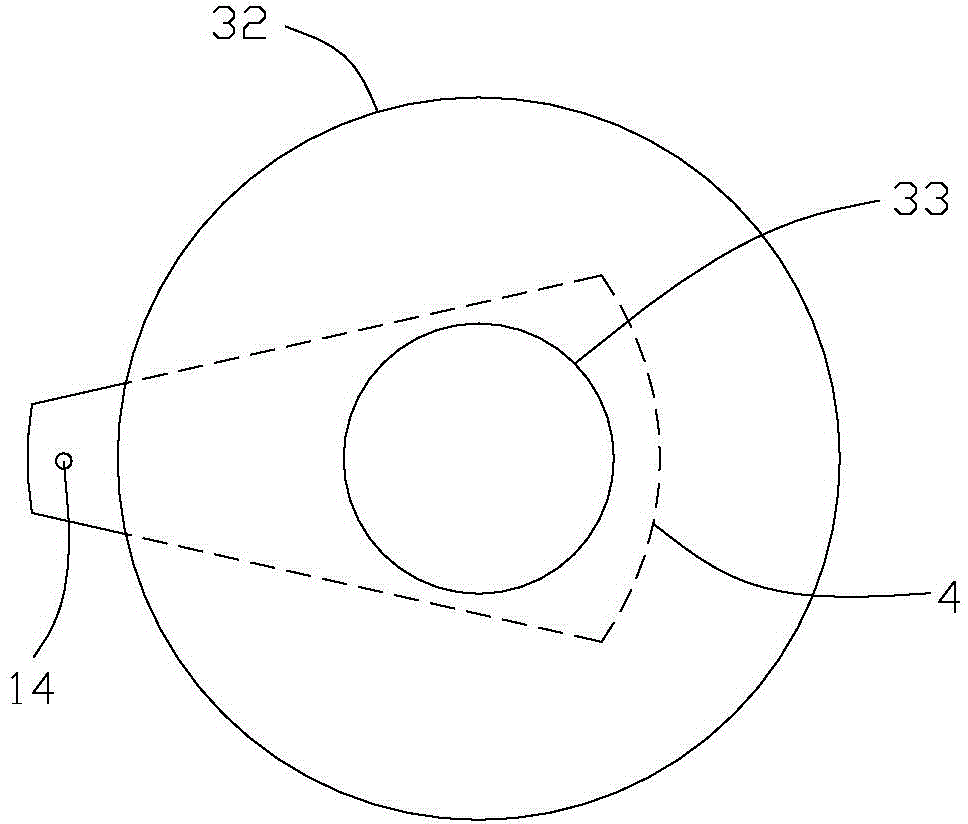

[0018] Combine below figure 1 , figure 2 , image 3 and Figure 4 The automatic feeder of the present invention is introduced in detail, including a hollow rotating shaft 2 driven by a motor 1, the upper end of the rotating shaft is provided with a storage room 3 for storing feed, and the storage room is communicated with the inner cavity 21 of the rotating shaft through a lower material door 4, and the rotating shaft The lower end extends into a mixing chamber 5, which communicates with the inner cavity of the rotating shaft, and a stirring blade 6 is fixed at the lower end of the rotating shaft, and a water pump 7 delivers water to the mixing chamber; the lower side of the mixing chamber is provided with a circular Feeding chamber 8, the bottom of the mixing chamber communicates with the feeding chamber through the discharge door 9; several feeding areas 10 are distributed on the outer periphery of the bottom of the feeding chamber, and each feeding area communicates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com