Lens cleaning device

A technology for cleaning devices and lenses, which is applied in the directions of cleaning methods using liquids, cleaning flexible objects, cleaning methods and utensils, etc., and can solve the problems of low applicability and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

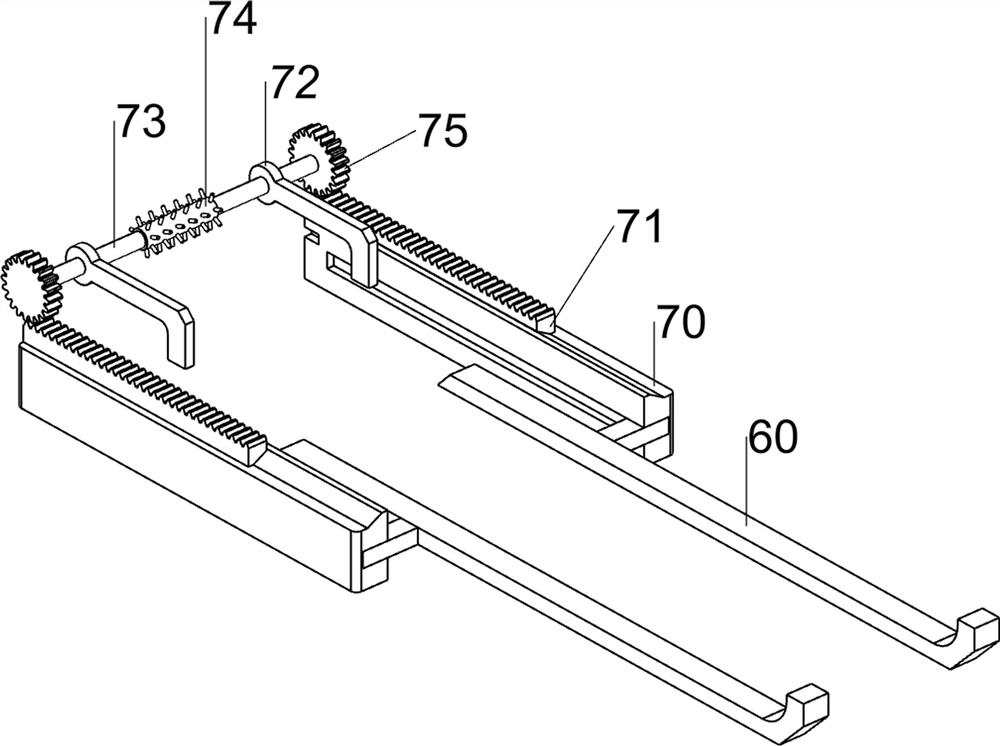

[0066] A device for lens cleaning, such as figure 1 As shown, it includes a base 1, a support 2, a detergent adding mechanism 3, a flushing mechanism 4 and a cleaning frame 9. Two supports 2 are connected to the front and rear sides of the upper part of the base 1, and the upper side of the base 1 is connected to a cleaning frame 9. Cleaning The frame 9 is located on the left side of the support 2, the detergent adding mechanism 3 is slidably connected between the support 2, and the flushing mechanism 4 is connected between the front and rear sides of the upper part of the base 1.

[0067] When the device needs to be used, the user can place the lens in the cleaning frame 9, add detergent to the detergent adding mechanism 3, pour clean water into the flushing mechanism 4, and the user can pull the detergent to the left to add Mechanism 3, and then push the detergent adding mechanism 3 to the right, at this time, the detergent can drop from the detergent adding mechanism 3 to t...

Embodiment 2

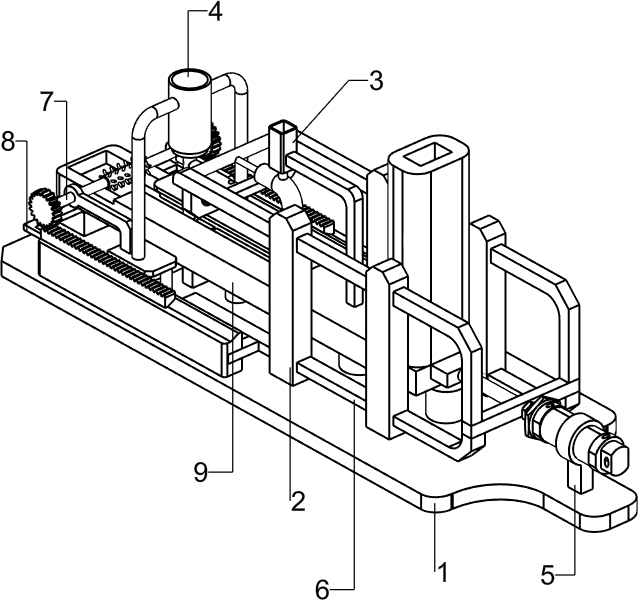

[0069] On the basis of Example 1, such as figure 2As shown, the detergent adding mechanism 3 includes a push rod 30, a support rod 31, a detergent bin 32, a moving rod 33, a piston 34 and an L-shaped pipe 35, and the upper parts of the two brackets 2 on the same side are slidingly connected. There is a push rod 30, a moving rod 33 is connected between the inner side of the left part of the pushing rod 30, a piston 34 is connected to the right side of the moving rod 33, an L-shaped pipe 35 is connected to the outside of the piston 34 in a sliding manner, and a washing machine is connected to the upper side of the L-shaped pipe 35. The detergent material box 32 is connected with a support rod 31 on the right side of the detergent material box 32 .

[0070] After the user places the lens in the cleaning frame 9, the detergent is added to the detergent material box 32, the cleaning water is poured into the flushing mechanism 4, the user can pull the moving rod 33 to the left, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com