The locking structure of the sliding sleeve of the main shaft of the centering machine and the claw

A technology of locking structure and walking machine, which is applied in the directions of metal processing machinery parts, clamping, and support, can solve the problems of easy deformation and low rigidity of the ejector rod, and achieve the effect of increasing rigidity, solving easy deformation and improving rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

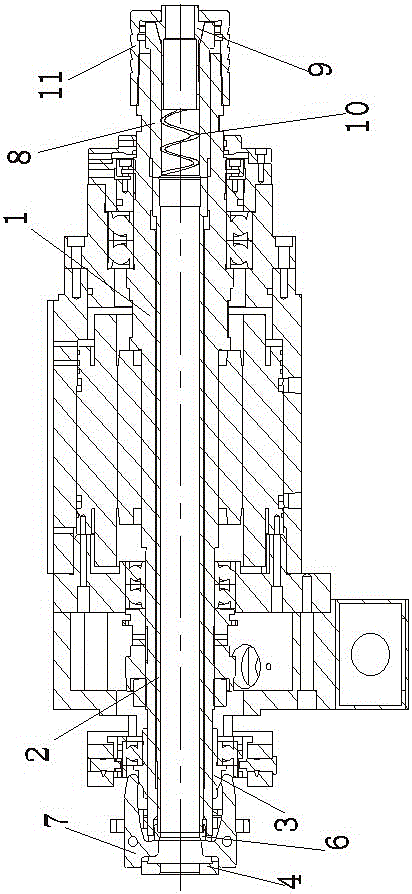

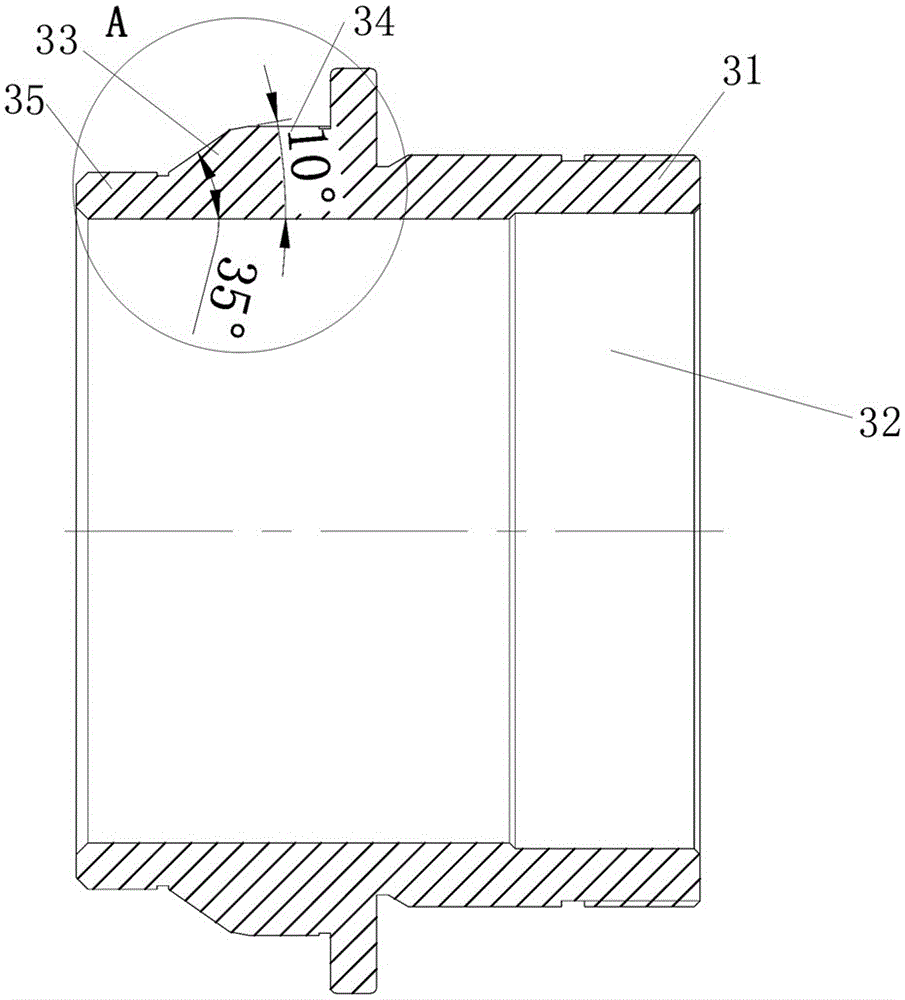

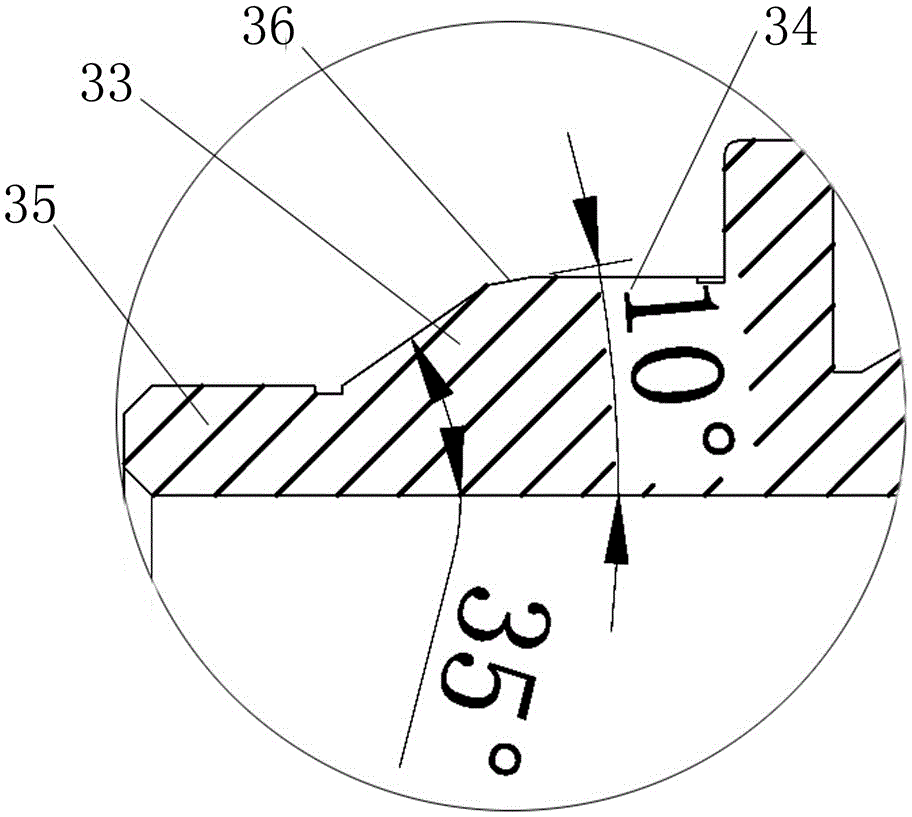

[0020] Such as figure 1 The shown locking structure of the sliding sleeve of the main shaft of the walking machine with the jaws includes a main shaft 1 with a first central hole penetrating both ends of the main shaft 1 along the axial direction; A movable mandrel 2; a jacket 8 that is arranged in the front end of the first central hole of the main shaft 1 and can be pushed by the mandrel 2 to move axially. The jacket 8 has a second central hole penetrating both ends of the jacket 8 in the axial direction. The front end of the center hole is provided with a chuck 9 (standard part, available in the market according to the required model) and the front end of the second center hole is a horn with a large front end and a small rear end that matches the chuck 9 The rear end of the second central hole is provided with a compression spring 10, the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com